The Ultimate Guide to Caterpillar Excavator Parts: Everything You Need to Know

I understand the importance of creating high-quality, original, and optimized content that can effectively market products or services. I will provide detailed information about Caterpillar excavator parts, focusing on Kyotechs' comprehensive range of offerings. By utilizing the keyword "caterpillar excavator parts" strategically throughout the article, I will ensure that the content is not only informative but also optimized for search engines.

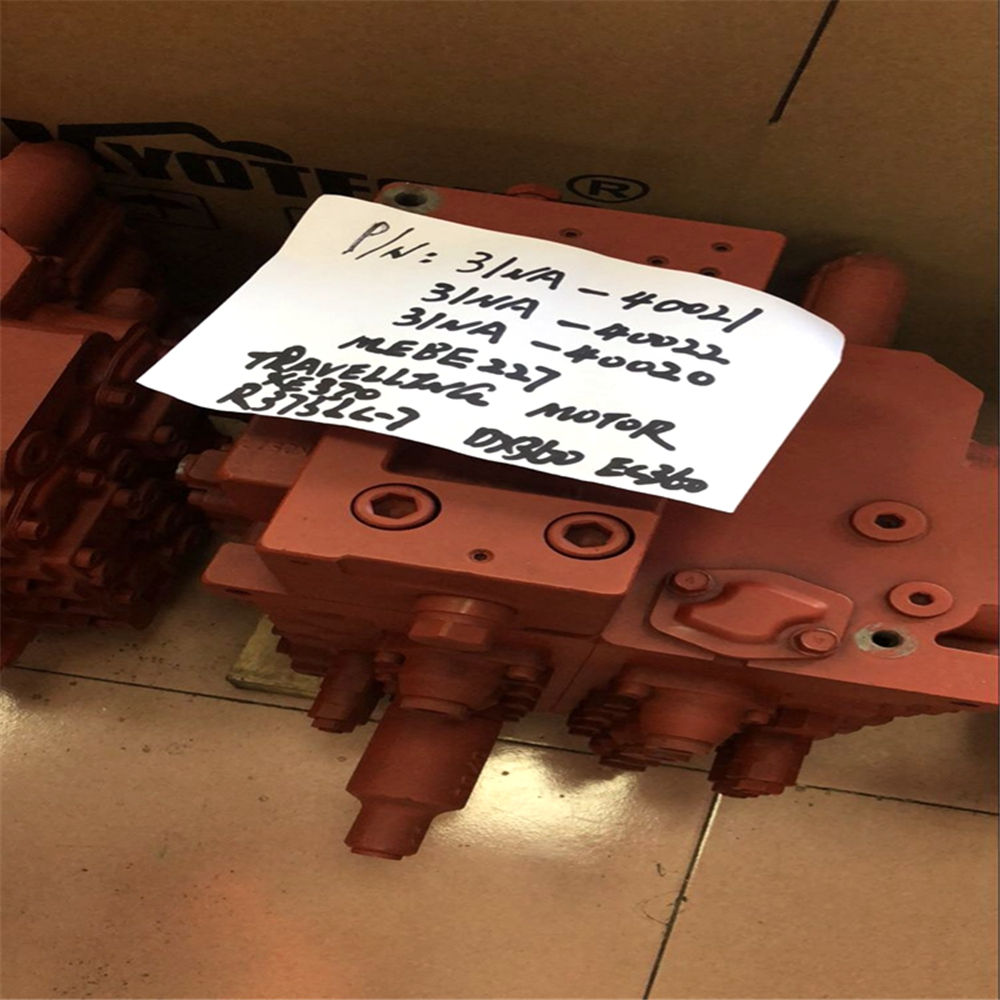

At Kyotechs, customers can find a wide array of parts for various excavator brands such as Hitachi, Sany, Kawasaki, Volvo, Hyundai, Doosan, Komatsu, Caterpillar, Case, and Kobelco. The product range includes engine assemblies and parts, hydraulic pumps and parts, hydraulic motor assemblies and parts, control valve assemblies and parts, cylinder assemblies and seal kits, driving cabin assemblies and inside parts, electric parts, undercarriage parts, mini excavator, pile drivers, hammers, and more. This extensive selection ensures that customers can find all the necessary parts to meet their specific excavation needs.

1. Understanding Caterpillar Excavator Parts

In this section, I will provide an overview of the different types of Caterpillar excavator parts and their functions. I will explain the importance of quality parts in ensuring the optimal performance and longevity of excavators.

2. Engine Assemblies and Parts

I will delve into the details of engine assemblies and parts offered by Kyotechs, highlighting their compatibility with Caterpillar excavators and their role in powering these heavy machinery.

3. Hydraulic Pumps and Parts

This section will focus on the hydraulic pumps and parts available for Caterpillar excavators, explaining their significance in facilitating the movement and operation of the machine's hydraulic system.

4. Control Valve Assemblies and Parts

I will provide an in-depth explanation of control valve assemblies and parts, emphasizing their role in regulating the flow of hydraulic fluid within the excavator's hydraulic system.

5. Cylinder Assemblies and Seal Kits

In this section, I will discuss the importance of cylinder assemblies and seal kits, detailing how they contribute to the smooth and efficient operation of Caterpillar excavators.

6. Electric Parts

I will highlight the range of electric parts offered by Kyotechs, emphasizing their crucial role in powering and controlling various electrical components of Caterpillar excavators.

7. Undercarriage Parts

This section will focus on the undercarriage parts available for Caterpillar excavators, explaining how they contribute to the stability and mobility of the machine during excavation tasks.

8. Mini Excavator, Pile Drivers, and Hammers

Finally, I will discuss additional equipment such as mini excavators, pile drivers, and hammers, outlining their significance in expanding the capabilities of Caterpillar excavators for diverse construction and excavation projects.

Conclusion

In conclusion, I will reiterate the comprehensive range of Caterpillar excavator parts offered by Kyotechs and emphasize the company's commitment to providing high-quality, reliable parts for various excavator brands. I will also encourage readers to explore Kyotechs' product range to find the perfect parts for their excavation needs.

FAQs

1. What types of Caterpillar excavator parts does Kyotechs offer?

- Kyotechs offers a wide range of parts, including engine assemblies, hydraulic pumps, control valve assemblies, cylinder assemblies, electric parts, undercarriage parts, and more for Caterpillar excavators.

2. Are Kyotechs' excavator parts compatible with other excavator brands?

- Yes, Kyotechs' parts are designed to be compatible with various excavator brands, ensuring versatility and flexibility for customers' equipment needs.

3. Can Kyotechs provide custom solutions for specific excavation requirements?

- Kyotechs has the capability to provide custom solutions tailored to customers' specific excavation needs, ensuring optimal performance and efficiency.

4. How does Kyotechs ensure the quality of its excavator parts?

- Kyotechs maintains stringent quality control measures and works with reputable manufacturers to ensure the quality and reliability of its excavator parts.

5. Does Kyotechs provide warranty or after-sales support for its excavator parts?

- Yes, Kyotechs offers warranty options and after-sales support to ensure customer satisfaction and peace of mind when using its excavator parts.

Your Ultimate Guide to John Deere 290D Excavator Parts – Kyotechs

Get the Most Out of Your Excavator with the 9224BG1 Liner Kit from Kyotechs

Kyotechs best professional volvo excavator parts Manufacturers and supplier brand

Wholesale Kobelco excavator parts manufacturer and supplier

FAQS

What should be done if an excavator engine has trouble starting?

If the engine has trouble starting, first check the battery charge and connections. Ensure the fuel system is supplying fuel by inspecting the fuel pump and fuel lines for blockages. Check the glow plugs (for diesel engines) or spark plugs (for gasoline engines) for wear and replace them if necessary. Use a diagnostic tool to check for any fault codes that might indicate issues with the engine control unit (ECU) or sensors.

How to avoid the derailment (chaining) of the crawler chain of the excavator?

1. When walking on the construction site, please try to place the travel motor behind the walking to reduce the squeezing of the sprocket.

2. The continuous walking time of the machine cannot exceed 2 hours. The walking time on the construction site should be minimized. If necessary, it is recommended to walk after a short stop in the middle.

3. Avoid raised hard objects when walking to avoid stress concentration on the track chain.

4. Confirm the tightness of the crawler, adjust the crawler tighter in soft places such as soil, and adjust the crawler looser when walking on stones. It is not good to have a crawler that is too loose or too tight. Too loose will cause the crawler to derail easily, and too tight will cause the chain sleeve to wear too quickly.

5. Check whether there are foreign objects such as stones in the crawler frequently, and clean them if there are.

6. When working on a muddy construction site, it is necessary to frequently idle to discharge the soil deposited in the crawler.

7. Try to avoid the excavator turning in circles on the spot.

8. Regularly check the rail guard and the rail guard welded under the guide wheel.

What should be checked when the hydraulic pump has insufficient pressure?

When the pressure is insufficient, check the hydraulic oil level, filter, hydraulic line leakage, pressure relief valve and internal wear of the pump.

How to address travel system issues in an excavator?

Inspect the tracks, travel motors, and travel reducers. Test the pressure and flow of the hydraulic drive system, check if the control valves are functioning correctly, and perform necessary repairs or replacements.

What to do if the excavator's fuel system is clogged?

Check and clean the fuel filters, clean sediment from the fuel tank, inspect the fuel lines for blockages or leaks, and use appropriate cleaning agents to flush the fuel system.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs