Discover the 1698Slewing Gear Reduction

Introducing the 1698Slewing Gear Reduction, a revolutionary solution for smooth and efficient gear reduction. This innovative product is designed to optimize performance and deliver unparalleled results, making it the ideal choice for a wide range of applications.

With its advanced technology and precision engineering, the 1698Slewing Gear Reduction offers unmatched durability and reliability. Its compact design and superior construction ensure seamless operation, while its high-quality materials guarantee long-lasting performance. Whether you're tackling heavy-duty tasks or demanding industrial projects, this gear reduction system is built to handle the toughest challenges with ease.

One of the key advantages of the 1698Slewing Gear Reduction is its ability to provide exceptional power transmission while reducing friction and wear. This results in improved efficiency, reduced maintenance requirements, and extended equipment lifespan. Additionally, its smooth and quiet operation enhances overall workplace safety and comfort, creating a more productive and enjoyable user experience.

Thanks to its user-friendly design and easy installation process, the 1698Slewing Gear Reduction is suitable for both professionals and DIY enthusiasts. Its intuitive interface and hassle-free maintenance make it a hassle-free addition to any operation. Plus, its compatibility with a variety of equipment and machinery makes it a versatile and cost-effective solution for countless industrial and commercial settings.

In summary, the 1698Slewing Gear Reduction is a game-changer in the world of gear reduction systems. Its exceptional performance, durable construction, and user-friendly design set it apart from the competition, making it the go-to choice for anyone seeking superior quality and unmatched reliability.

Our Advantages

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

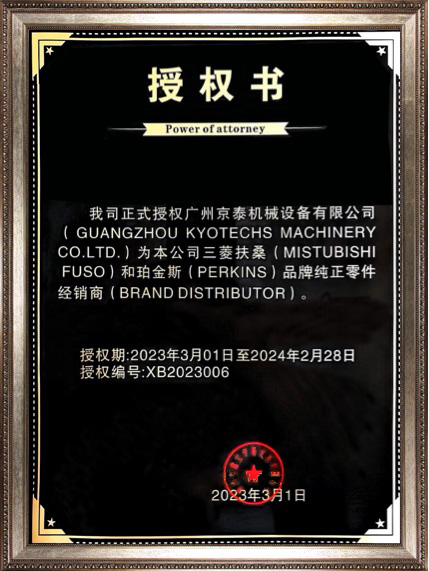

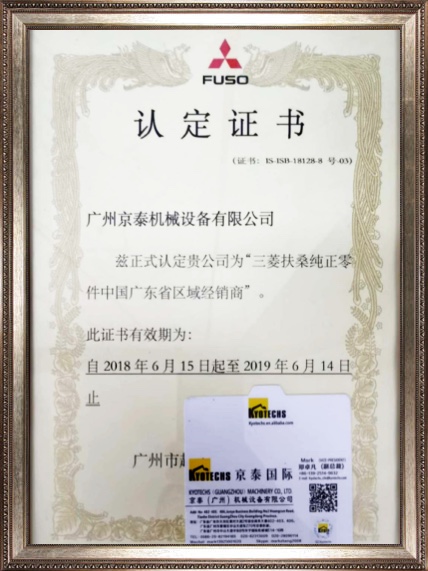

Our Certifications

Perkins

MITSUBISHI FUSO

WYS

Question you may concern

What are the reasons that may cause the excavator engine to emit blue smoke?

Blue smoke when starting a cold car: It is normal for a cold car to emit blue smoke and disappear after the car is heated, because a small amount of oil will invade the engine combustion chamber after the shutdown. Continuous blue smoke after starting:

1. The diesel filter is clogged, check whether the oil type is correct;

2. The engine piston ring and valve oil seal are worn, affecting the oil in the intake or exhaust pipe, which causes the excavator to emit blue smoke;

3. The clearance between the piston and the cylinder liner is too large, causing blue smoke;

What should I pay attention to when assembling a gear pump?

The pump housing will wear more in the oil inlet chamber. If the pump housing is symmetrical, it can be turned 180 degrees. Then use it. For the passive gear, the two ends cannot be replaced. Make a mark when removing it. Because the gear will wear on one side. The active gear is integrated with the rotating shaft and cannot be turned over; turning the passive gear over can change the contact point of the meshing line of the two gears. After the pump is assembled, add a little lubricating oil and rotate it slightly by hand. The feel should be smooth.

What should be done if the tracks are severely worn?

If the tracks are severely worn, they should be replaced promptly to avoid further damage and safety hazards. Ensure that the new tracks match the specifications of the original tracks and are installed correctly.

Why does the hydraulic pump vibrate excessively?

Possible loose installation, unbalanced pump components, or cavitation.

Solution: Tighten installation, balance pump components, check and eliminate cavitation sources.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs