High-Quality Excavator Track Motor Parts for Reliable Performance

When it comes to excavator track motor parts, our company offers a comprehensive range of high-quality components that are designed to meet the demanding needs of heavy-duty machinery. Our track motor parts are manufactured with precision and durability in mind, ensuring reliable performance and long-lasting use.

We understand the importance of delivering a product that exudes professionalism and reliability. That's why our excavator track motor parts are engineered to the highest standards, providing consumers with peace of mind and confidence in their equipment. Whether it's for construction, mining, or other industrial applications, our parts are built to withstand the toughest conditions, making them a trusted choice for professionals in the field.

In addition to the superior quality of our products, we also prioritize user-friendliness. Our excavator track motor parts are easy to install and maintain, allowing for seamless integration into existing machinery without the hassle. This ensures a smooth and efficient operation, reducing downtime and maximizing productivity.

Furthermore, our dedication to providing valuable and informative content extends to how easily our product descriptions can be crawled and ranked by search engines like . This enhances the accessibility of our products to potential consumers, ensuring that they can easily find the parts they need for their excavators.

In summary, our excavator track motor parts offer unmatched quality, reliability, and user-friendliness, making them the top choice for professionals in the industry.

Our Advantages

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

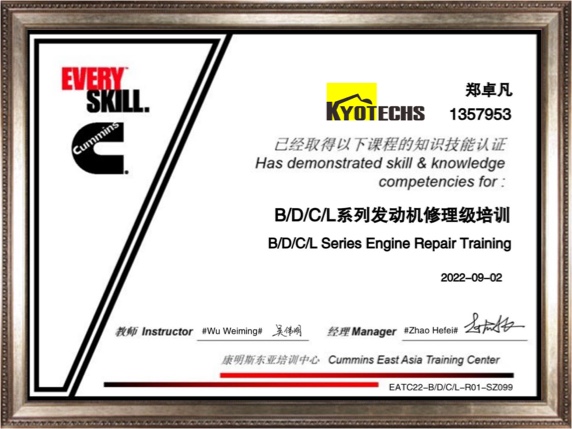

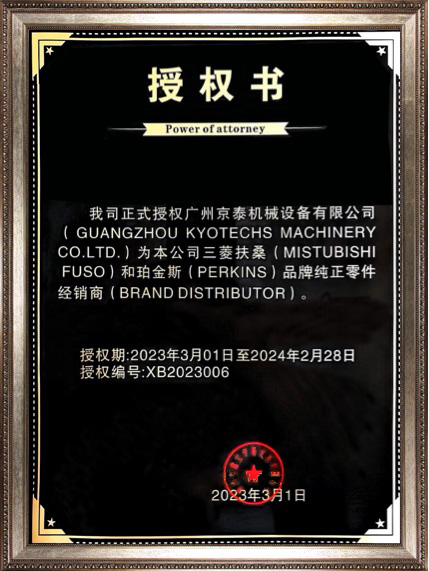

Our Certifications

Cummins REPAIR TRAINING

WYS

Perkins

Q&A

How to remove air from the hydraulic system?

The way to remove air is to slowly operate all functions of the hydraulic system until the air is exhausted, and check and maintain the hydraulic oil level during this process.

Digging powerlessness is one of the typical faults of excavators

Digging powerlessness can be divided into two situations: one is digging powerlessness, the engine does not hold back, and the load feels very light; the second is digging powerlessness, when the boom or dipper stick is extended to the bottom, the engine is seriously held back or even stalled.

①, digging powerlessness but the engine does not hold back. The magnitude of the digging force is determined by the output pressure of the main pump, and whether the engine holds back depends on the relationship between the oil pump absorption torque and the engine output torque. The engine does not hold back, indicating that the oil pump absorption torque is small and the engine load is light. If the working speed of the excavator is not obviously abnormal, the maximum output pressure of the main pump, that is, the system overflow pressure, should be checked in particular. If the overflow pressure measurement value is lower than the specified value, it indicates that the overload overflow valve setting value of the hydraulic circuit of the mechanism is incorrect, resulting in premature overflow of the mechanism and powerlessness. The machine can be adjusted by turning the adjustment screw.

②, digging powerlessness, engine holding back. The engine holding back indicates that the absorption torque of the oil pump is greater than the engine output torque, causing the engine to overload. This fault should first check whether the engine speed sensing system is normal, and the inspection method is similar to the engine inspection method described above. After the above detailed inspection and troubleshooting, the engine speed sensing system will resume normal function, the engine stalling phenomenon will disappear, and the digging force will return to normal.

Which oil level is the most suitable for the oil cylinder?

There are usually the highest and lowest oil level marks (MAX and MIN) on the inner wall of the oil filling port of each engine. This means that the oil level cannot exceed MAX or be lower than MIN.

A lower oil level, that is, a decrease in the amount of oil in the engine, will increase the oil load, causing the oil to become more seriously contaminated by heat, which not only weakens the lubrication performance, but also increases the fuel consumption. Because the less oil in the engine, the higher the oil temperature; and the higher the oil temperature, the greater the fuel consumption will be as the oil temperature rises. It is very dangerous to run the engine when the oil level is at the lowest point (MIN).

Keeping the oil level at the highest point (MAX) all the time will cause the oil to foam and lead to insufficient lubrication, resulting in serious wear. Foaming oil will also increase fuel consumption.

Therefore, it is recommended to keep the engine oil level between the MAX and MIN marks at a position close to one-third of the MAX.

What is the mission and vision of kyotechs?

In the field of modern engineering machinery, excavators play a vital role, and behind this, there is a company that is quietly adding momentum to the industry, that is Kyotechs. With the mission of "building a community of shared destiny for partners and adding strength to the excavator industry", Kyotechs is not only committed to providing high-quality excavator parts, but also promoting the development of the entire industry with a long-term vision and innovative thinking.

In an increasingly competitive market environment, the era of fighting alone is over, and win-win cooperation is the key to future development. Therefore, the company has always been committed to building a close community of shared destiny for partners. This is not just a simple business cooperation, but also a deep collaboration based on trust, mutual assistance and common goals.

In this community of shared destiny, Kyotechs shares information, resources and opportunities with suppliers, customers, technical partners and other relevant parties. In this way, the company can not only respond quickly to market needs, but also foresee and respond to industry challenges in advance. The success of our partners is our success. It is this concept of symbiosis and win-win that has established a good reputation for Kyotechs in the industry.

As a company focusing on excavator parts, Kyotechs' products cover hydraulic pumps, engine parts, electronic controllers, transmission system parts and other fields. These high-quality parts not only ensure the efficient operation of the excavator, but also play an important role in improving overall engineering efficiency and reducing equipment failures.

Kyotechs not only pursues commercial success, but also takes "becoming a happy person in the field of excavation equipment" as its vision, emphasizing the happiness and satisfaction of all stakeholders. This vision reflects the company's deep care for employees, customers and society.

For Kyotechs, customer satisfaction is an important criterion for measuring our success. The company has always been customer-oriented and provides high-quality products and a full range of services. Whether it is product quality, delivery speed or after-sales service, Kyotechs strives to do its best to ensure that every customer can enjoy an experience beyond expectations.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs