How Does an Excavator Hydraulic Pump Work? What Are the Different Types of Hydraulic Pumps?

Discover how an excavator hydraulic pump works, from its core mechanics to efficient operation, and explore the different types of hydraulic pumps, including gear, vane, and piston varieties. Kyotechs offers expert insights for optimal performance.

- 3 Types of Hydraulic Pumps Used in Excavators

- 1.Gear Pumps

- 2.Vane Pumps

- 3.Piston Pumps

- How Do Hydraulic Pumps Work?

- 1.Mechanical Input

- 2.Fluid Intake

- 3.Fluid Displacement

- 4.Pressure Distribution

- 5.Return Cycle

- How Can a Hydraulic Pump Be Repaired?

- 1.Diagnosis

- 2.Disassembly

- 3.Part Replacement

- 4.Reassembly

- 5.Testing

- Is a Refurbished Hydraulic Pump a Good Option?

- Conclusion

- FAQs

- Q1. How to Clean a Hydraulic Ram Pump?

- Q2. How to Adjust the Stroke Length?

- Q3. Can a Hydraulic Ram Pump Lift Water Uphill?

- Q4. How Much Water Flow is Needed?

- Q5.Is Pressure Adjustment Necessary for New Hydraulic Systems?

- Q6. Are There Hydraulic Pumps with Automatic Pressure Adjustment?

Excavators are workhorses in construction, mining, and agriculture, and their power comes largely from hydraulic systems. At the heart of these systems is the hydraulic pump, a critical component that converts mechanical energy into hydraulic energy. Understanding how these pumps work, their types, and maintenance can help operators and fleet managers keep equipment running efficiently.

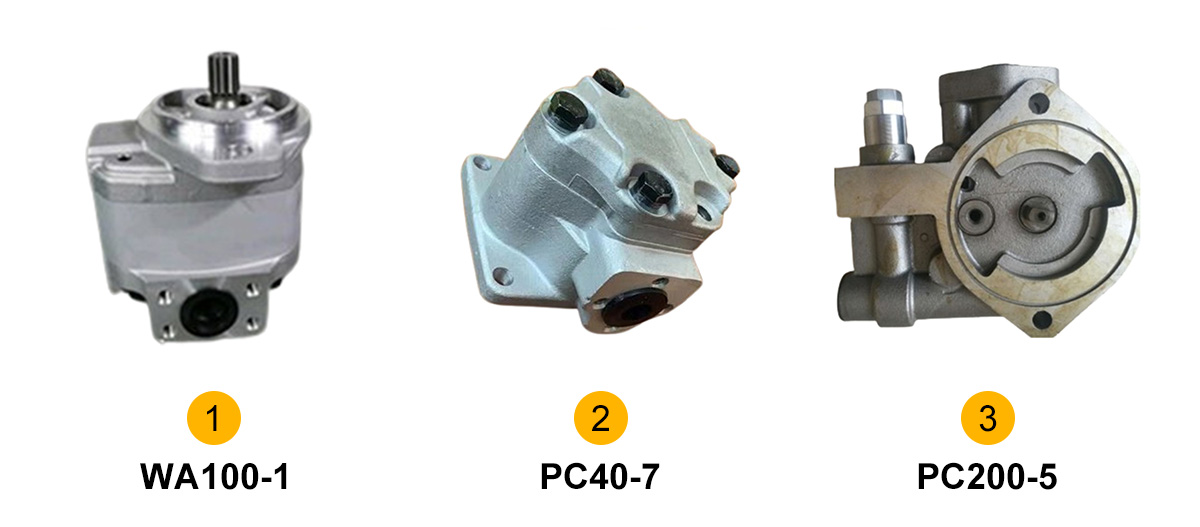

3 Types of Hydraulic Pumps Used in Excavators

Hydraulic pumps in excavators are categorized based on their displacement characteristics and operational principles. The three primary types are:

1.Gear Pumps

Gear pumps are the simplest and most cost-effective hydraulic pumps, consisting of two intermeshing gears housed in a casing. As the gears rotate, they create a vacuum at the inlet, drawing hydraulic fluid in. The fluid is then trapped between the gear teeth and the casing, moving it to the outlet side where it’s discharged under pressure.

Gear pumps are valued for their compact size, low maintenance needs, and ability to handle high-viscosity fluids. However, they are less efficient than other types and are typically used in low-pressure applications, such as auxiliary systems in smaller excavators.

2.Vane Pumps

Vane pumps use a rotor with sliding vanes that press against the inner surface of an eccentrically mounted casing. As the rotor spins, the vanes extend and retract, creating expanding and contracting chambers. This action draws fluid into the expanding chambers and pushes it out through the contracting ones.

These pumps offer higher efficiency than gear pumps and operate more smoothly, making them suitable for medium-pressure systems. They are often used in excavator hydraulic circuits requiring consistent flow, such as those controlling the boom or bucket.

3.Piston Pumps

Piston pumps are the most efficient and powerful option, designed for high-pressure applications in large excavators. They use a series of reciprocating pistons within a cylinder block. As the block rotates, the pistons move in and out, drawing fluid in during the intake stroke and forcing it out under high pressure during the compression stroke.

Piston pumps are further divided into axial (pistons parallel to the drive shaft) and radial (pistons arranged radially) designs. Axial piston pumps are more common in excavators due to their high power density and ability to vary flow rates, adapting to changing loads.

How Do Hydraulic Pumps Work?

Hydraulic pumps operate on the principle of Pascal’s Law, which states that pressure applied to a fluid in a closed system is transmitted equally in all directions. Here’s a step-by-step breakdown of their operation in an excavator:

1.Mechanical Input

The pump is driven by the excavator’s engine, typically via a driveshaft or belt, converting rotational mechanical energy into hydraulic energy.

2.Fluid Intake

As the pump’s internal components (gears, vanes, or pistons) rotate, they create a low-pressure zone at the inlet port, drawing hydraulic fluid from the reservoir.

3.Fluid Displacement

The fluid is trapped and moved through the pump’s housing to the outlet port, where the volume is reduced, increasing pressure.

4.Pressure Distribution

The pressurized fluid is sent through hydraulic hoses to actuators (cylinders or motors), which convert the hydraulic energy back into mechanical motion—powering the excavator’s arm, bucket, or tracks.

5.Return Cycle

After acting on the actuators, the fluid returns to the reservoir, where it’s filtered and cooled before being recirculated.

This closed-loop system ensures efficient power transmission, allowing excavators to lift heavy loads and perform precise movements with minimal energy loss.

How Can a Hydraulic Pump Be Repaired?

Hydraulic pump failure can halt operations, so timely repairs are crucial. Common issues include leaks, reduced pressure, strange noises, or overheating. Here’s a general repair process:

1.Diagnosis

Technicians use pressure gauges, flow meters, and visual inspections to identify problems. Leaks may stem from damaged seals or loose fittings, while noise could indicate cavitation (air in the system) or worn components.

2.Disassembly

The pump is removed from the excavator and disassembled in a clean environment to avoid contaminating internal parts.

3.Part Replacement

Worn or damaged components—such as gears, vanes, pistons, bearings, or seals—are replaced with OEM (Original Equipment Manufacturer) or high-quality aftermarket parts.

4.Reassembly

The pump is reassembled with precise torque specifications to ensure proper alignment and function.

5.Testing

After reinstallation, the system is tested for pressure, flow, and leaks. Fluid levels and filtration are checked to prevent future issues.

Preventive maintenance, such as regular fluid checks, filter replacements, and keeping the system clean, can reduce the need for major repairs.

Is a Refurbished Hydraulic Pump a Good Option?

Refurbished hydraulic pumps—those rebuilt to meet OEM specifications—can be a cost-effective alternative to new pumps, but their suitability depends on several factors:

Pros:

Lower Cost: Refurbished pumps typically cost 30–50% less than new ones, making them ideal for budget-conscious operations.

Sustainability: Reusing components reduces waste and environmental impact.

Reliability: Reputable refurbishers test pumps rigorously, ensuring they meet performance standards.

Cons:

Shorter Warranty: Refurbished pumps often have shorter warranties than new ones.

Quality Variability: Poorly refurbished pumps may fail prematurely, so choosing a trusted supplier is critical.

A refurbished pump is a good option if it’s certified by a reputable provider, comes with a warranty, and the cost savings align with your maintenance budget. For critical applications where downtime is costly, a new pump may be more reliable.

Conclusion

The hydraulic pump is the lifeline of an excavator’s hydraulic system, enabling its powerful and precise movements. Understanding the differences between gear, vane, and piston pumps helps in selecting the right equipment for specific tasks. Proper maintenance and timely repairs—whether using new or refurbished parts—ensure longevity and efficiency. By prioritizing pump care, operators can maximize uptime and extend the lifespan of their excavators, ultimately boosting productivity on the job site.

If you are interested, please come and contact us

FAQs

Q1. How to Clean a Hydraulic Ram Pump?

A: Flush the system regularly to remove any sediment or debris that may affect pump efficiency.

Q2. How to Adjust the Stroke Length?

A: Most ram pumps have adjustable settings. Follow the manufacturer's guidelines to adjust the stroke length for optimal performance.

Q3. Can a Hydraulic Ram Pump Lift Water Uphill?

A: Yes, a hydraulic ram pump is able to lift water to a certain height, making it suitable for a variety of terrains.

Q4. How Much Water Flow is Needed?

A: The required water flow rate depends on the specific ram pump model. Please check the manufacturer's recommendations for the optimal flow rate.

Q5.Is Pressure Adjustment Necessary for New Hydraulic Systems?

A: Yes, even new systems may require adjustment to ensure they operate within specified parameters.

Q6. Are There Hydraulic Pumps with Automatic Pressure Adjustment?

A: Some advanced hydraulic systems may have automatic pressure control. Refer to the system specifications for details.

What is the reason why the excavator hydraulic pump makes abnormal noise?

How to Solve the Hydraulic Pump Overheating Problem?

How do I bleed air from the excavator's hydraulic cylinder?

What are the symptoms of hydraulic pump failure in excavators?

FAQS

What parts you have?

We are specialized in excavator spare parts, such as travel motor gearbox assy & parts, swing gearbox motor assy & parts, and hydraulic pump motor assy and spare parts. If any are needed, we can also supply them as per your requirements.

Do you only sell or repair?

Yes, we sell parts and have a repair team to offer support.

1. Software solution.

A. ECU & Monitor Reprogram

B. DPF Program Solution

C. Software refit

2. Engine Rebuild & Testing

Maintenance Team Support

A. ET for Caterpillar Diagnosis

B. Inline 6 for Cummins/Komatsu/Hyundai Diagnosis

C. IDSS for Hitachi/Isuzu/Case/Sany/Sumitomo/JCB/XCMG/Isuzu Truck Diagnosis

D. DX2/NEXIQ for Kobelco/Hino truck Diagnosis

E. Vocom for Volvo/Volvo truck/Penta Diagnosis

F. DST-i for KUBOTA DENSO Diagnosis

3. hydraulic Remanufacture & Testing

A. Offer new or rebuilt hydraulic pump & motor

B. Control valve & main pump repair & rebuild knowledge

C. Offer stable and cheap hydraulic test machines

D. All rebuild valves, pumps, and motors offer testing video for cilent

If i don'thave part number, can you check for me?

Yes, excavator model, old photos, and size are also available to confirm the correct parts you need.

Which shipping term you can supply?

By sea, air or by express ( DHL, Fedex, TNT, UPS, EMS)

How long does it take to my address?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs