What are the possible faults of diesel injection pump?

- What Causes Diesel Injection Pump Failure?

- 1.Fuel Contamination

- 2.Poor Fuel Quality

- 3.Lack of Lubrication

- 4.Air in the Fuel System

- 5.Excessive Heat

- 6.Wear and Tear

- 7.Incorrect Timing

- What Are The Diesel Injector Pump Failure Symptoms?

- 1.Hard Starting

- 2.Loss of Power

- 3.Rough Idling

- 4.Increased Fuel Consumption

- 5.Smoke from Exhaust

- 6.Engine Misfires

- 7.Unusual Noises

- 8.Check Engine Light

- How To Diagnose Diesel Injection Pump?

- 1.Preliminary Checks:

- 2.Pressure Testing:

- 3.Timing Verification:

- 4.Visual Inspection:

- 5.Professional Diagnostics:

- Diesel Injection Pump Troubleshooting Techniques

- 1.Bleeding the Fuel System

- 2.Filter Replacement

- 3.Fuel System Cleaning

- 4.Timing Adjustment

- 5.Seal and Gasket Replacement

- 6.Pressure Regulator Adjustment/Replacement

- 7.Professional Repair or Rebuild

- 4 Ways To Prevent Common Fuel Injection Pump Failure

- 1.Use High-Quality Fuel

- 2.Regular Filter Maintenance

- 3.Proper Engine Operation

- 4.Scheduled Maintenance

- Conclusion

The diesel injection pump is a critical component in diesel engines, responsible for delivering precisely measured fuel to the combustion chamber at the right pressure and timing. When this component fails, it can lead to poor engine performance, increased fuel consumption, and even complete engine shutdown. This guide will help you understand, diagnose, and troubleshoot common diesel injection pump issues.

What Causes Diesel Injection Pump Failure?

Several factors can contribute to diesel injection pump failure, often related to contamination, wear, or improper maintenance:

1.Fuel Contamination

Water, dirt, or debris in the fuel system is one of the leading causes. These contaminants can scratch precision components, block passages, and accelerate wear.

2.Poor Fuel Quality

Using low-quality diesel or fuel with incorrect viscosity can cause premature pump wear and deposits.

3.Lack of Lubrication

Diesel fuel serves as both a combustible material and a lubricant for the pump. Insufficient fuel flow can lead to increased friction and overheating.

4.Air in the Fuel System

Air bubbles disrupt fuel flow and pressure, causing erratic pump operation and potential damage.

5.Excessive Heat

High operating temperatures, often caused by overloading the engine or cooling system issues, can degrade pump components.

6.Wear and Tear

Over time, internal components like seals, O-rings, and plungers naturally wear out, reducing pump efficiency.

7.Incorrect Timing

Improperly adjusted injection timing can cause excessive stress on the pump and other engine components.

What Are The Diesel Injector Pump Failure Symptoms?

Recognizing the early signs of injection pump problems can help prevent costly repairs and downtime:

1.Hard Starting

The engine may crank excessively or fail to start altogether, especially in cold weather.

2.Loss of Power

Reduced acceleration and overall engine performance, particularly under load.

3.Rough Idling

The engine may run unevenly, vibrate excessively, or stall at idle.

4.Increased Fuel Consumption

A failing pump often delivers fuel inefficiently, leading to higher fuel usage.

5.Smoke from Exhaust

Black, white, or blue smoke can indicate improper fuel delivery. Black smoke typically means too much fuel, while white smoke may signal unburned fuel.

6.Engine Misfires

Cylinders may not fire properly, causing hesitation or uneven operation.

7.Unusual Noises

Knocking, ticking, or whining sounds from the engine compartment, particularly near the pump.

8.Check Engine Light

Modern vehicles may display diagnostic trouble codes related to fuel pressure or injection timing.

How To Diagnose Diesel Injection Pump?

Proper diagnosis requires a systematic approach and, in many cases, specialized tools:

1.Preliminary Checks:

· Inspect fuel filters for contamination and replace if necessary

· Check for fuel leaks in lines and connections

· Verify fuel level and quality

· Look for signs of air in the fuel system (bubbles in clear lines)

2.Pressure Testing:

· Use a fuel pressure gauge to measure system pressure at various engine speeds

·Compare readings to manufacturer specifications

·Low pressure may indicate a failing pump, while fluctuating pressure could signal internal wear

3.Timing Verification:

· Check injection timing using a timing light or specialized diesel timing tool

· Ensure timing marks align correctly according to manufacturer guidelines

· Incorrect timing often causes performance issues and can damage the pump

4.Visual Inspection:

· Examine the pump for oil leaks, which may indicate seal failure

· Check electrical connections (for electronic pumps)

· Look for signs of overheating or damage to pump housing

5.Professional Diagnostics:

· Dealerships and specialized shops can perform advanced tests using manufacturer-specific software

· These tests can analyze injection patterns, pressure curves, and electronic control module data

Diesel Injection Pump Troubleshooting Techniques

Depending on the diagnosis, several troubleshooting steps can be taken:

1.Bleeding the Fuel System

Remove air from the system by loosening bleed screws and pumping fuel until a steady stream flows without bubbles.

2.Filter Replacement

Install new fuel filters and ensure proper seating to prevent contamination.

3.Fuel System Cleaning

Use a specialized diesel fuel system cleaner to remove deposits from the pump and injectors.

4.Timing Adjustment

If timing is off, adjust according to manufacturer specifications. This is often best left to professionals.

5.Seal and Gasket Replacement

Replace worn seals and gaskets to prevent leaks and contamination.

6.Pressure Regulator Adjustment/Replacement

For pumps with adjustable regulators, ensure pressure settings match specifications. Replace faulty regulators.

7.Professional Repair or Rebuild

Major internal pump issues typically require professional rebuilding or replacement. This involves disassembling the pump, replacing worn components, and recalibrating to factory specifications.

4 Ways To Prevent Common Fuel Injection Pump Failure

Prevention is key to extending the life of your diesel injection pump:

1.Use High-Quality Fuel

Always purchase diesel from reputable sources and consider using fuel additives designed to clean and protect the fuel system.

2.Regular Filter Maintenance

Replace fuel filters at recommended intervals, and consider adding a secondary filtration system for extra protection.

3.Proper Engine Operation

Avoid prolonged idling, which can cause fuel to stagnate and form deposits. Allow the engine to reach operating temperature before putting it under heavy load.

4.Scheduled Maintenance

Follow the manufacturer's recommended service intervals for fuel system inspections and adjustments. This includes checking fuel pressure, timing, and overall pump condition.

Conclusion

The diesel injection pump is vital to your engine's performance and efficiency. By understanding the common causes of failure, recognizing early symptoms, and following proper diagnostic and troubleshooting procedures, you can minimize downtime and repair costs. Regular maintenance and preventive measures are the best ways to ensure your injection pump operates reliably for years to come. When in doubt, consult with a qualified diesel technician who has the expertise and tools to properly diagnose and repair complex injection system issues.

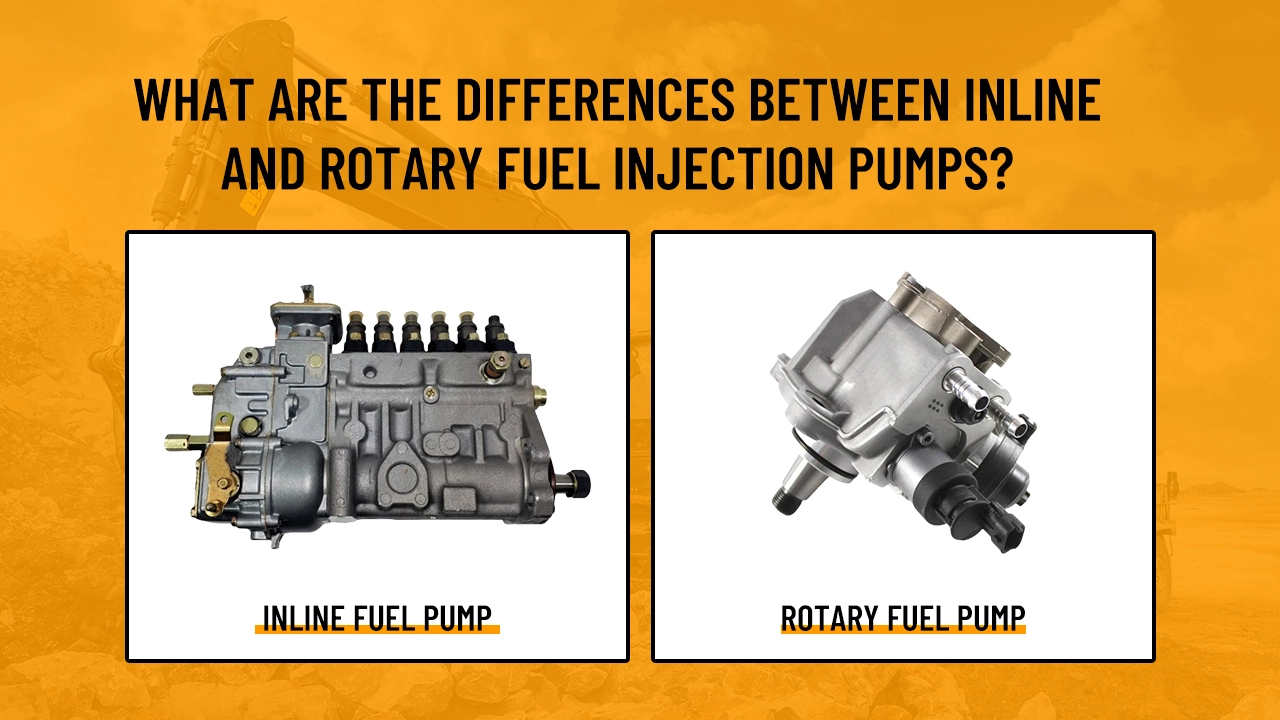

What are the differences between inline and rotary fuel injection pumps?

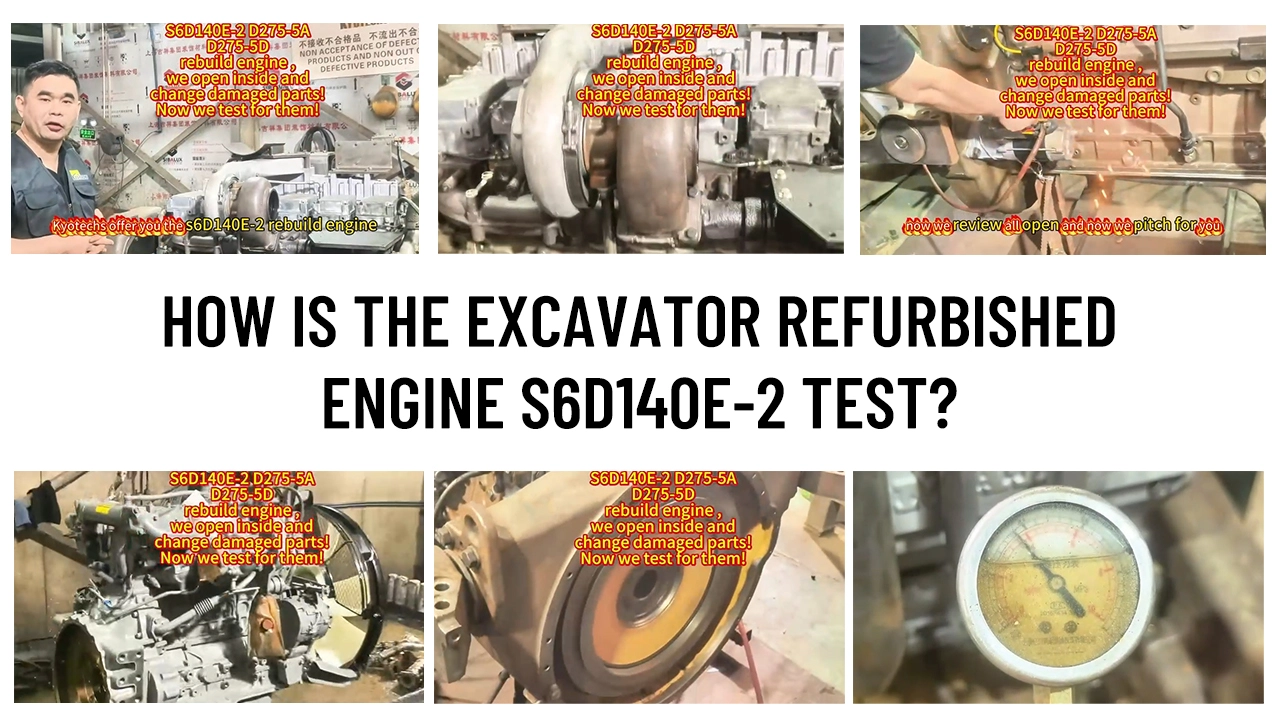

How is the excavator refurbished engine S6D140E-2 test?

How to check turbocharger oil leakage?

How to test the hydraulic main pump of an excavator?

FAQS

What parts you have?

We are specialized in excavator spare parts, such as travel motor gearbox assy & parts, swing gearbox motor assy & parts, and hydraulic pump motor assy and spare parts. If any are needed, we can also supply them as per your requirements.

Do you only sell or repair?

Yes, we sell parts and have a repair team to offer support.

1. Software solution.

A. ECU & Monitor Reprogram

B. DPF Program Solution

C. Software refit

2. Engine Rebuild & Testing

Maintenance Team Support

A. ET for Caterpillar Diagnosis

B. Inline 6 for Cummins/Komatsu/Hyundai Diagnosis

C. IDSS for Hitachi/Isuzu/Case/Sany/Sumitomo/JCB/XCMG/Isuzu Truck Diagnosis

D. DX2/NEXIQ for Kobelco/Hino truck Diagnosis

E. Vocom for Volvo/Volvo truck/Penta Diagnosis

F. DST-i for KUBOTA DENSO Diagnosis

3. hydraulic Remanufacture & Testing

A. Offer new or rebuilt hydraulic pump & motor

B. Control valve & main pump repair & rebuild knowledge

C. Offer stable and cheap hydraulic test machines

D. All rebuild valves, pumps, and motors offer testing video for cilent

If i don'thave part number, can you check for me?

Yes, excavator model, old photos, and size are also available to confirm the correct parts you need.

Which shipping term you can supply?

By sea, air or by express ( DHL, Fedex, TNT, UPS, EMS)

How long does it take to my address?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs