What's the difference between Gas Fuel Pump And Diesel Fuel Pump?

What's the difference between gas fuel pumps and diesel fuel pumps? At Kyotechs, we break it down: gas pumps handle volatile fuels with precision for efficiency, while diesel pumps focus on high-pressure delivery for robust engines. Explore our expert insights to choose wisely.

- What are the similarities between gas and diesel fuel pumps?

- What's the difference between a gas and diesel fuel pump?

- 1.Pressure requirements

- 2.Injection timing

- 3.Fuel delivery method

- 4.Construction materials

- 5.Injection location

- Which is more fuel-efficient, a gas or diesel fuel pump?

- Can a diesel fuel pump be used with gasoline?

- Conclusion

When it comes to heavy machinery like excavators, the fuel system plays a critical role in performance, efficiency, and longevity. Among the key components are the fuel pumps, which vary significantly depending on whether the excavator runs on gasoline or diesel. Understanding these differences is essential for proper maintenance, operation, and decision-making when selecting equipment.

What are the similarities between gas and diesel fuel pumps?

Despite their differences, gasoline and diesel fuel pumps in excavators share some fundamental similarities:

Both types of pumps are responsible for delivering fuel from the tank to the engine's combustion chamber. They must maintain a consistent flow rate to ensure the engine operates smoothly under varying loads—from idle to heavy digging operations.

Additionally, both systems incorporate filters to remove contaminants that could damage the engine. They also rely on seals and gaskets to prevent fuel leaks, which is crucial for safety and fuel efficiency in heavy machinery.

Finally, both gasoline and diesel pumps are designed to withstand the vibrations and harsh operating conditions typical in construction environments where excavators are used.

What's the difference between a gas and diesel fuel pump?

While they serve the same basic purpose, gasoline and diesel fuel pumps differ significantly in design and operation:

1.Pressure requirements

Diesel pumps operate at much higher pressures (often exceeding 20,000 psi) compared to gasoline pumps (typically 40-60 psi). This is because diesel fuel requires higher pressure for proper atomization in the combustion chamber.

2.Injection timing

Diesel pumps are precisely timed to inject fuel into the combustion chamber when compression reaches its peak. Gasoline pumps, on the other hand, deliver fuel earlier in the cycle, before the spark plug ignites the mixture.

3.Fuel delivery method

Gasoline pumps often use electric fuel pumps that push fuel through the system, while diesel pumps typically use mechanical or high-pressure common rail systems that compress and inject fuel directly.

4.Construction materials

Diesel pumps are built with stronger materials to withstand higher pressures and the lubricating properties of diesel fuel. Gasoline pumps use different materials compatible with gasoline's chemical composition.

5.Injection location

Diesel pumps inject fuel directly into the combustion chamber, while gasoline pumps deliver fuel either to the intake manifold or directly into the chamber in newer direct-injection gasoline engines.

Which is more fuel-efficient, a gas or diesel fuel pump?

Fuel efficiency in excavators is more about the engine type than the pump itself, but the pump's design complements the engine's efficiency characteristics.

Diesel engines, and consequently diesel fuel pumps, generally provide better fuel efficiency in heavy machinery like excavators. This is because diesel fuel contains more energy per gallon than gasoline, and diesel engines operate at higher compression ratios.

The high-pressure delivery system of diesel pumps ensures more complete combustion, extracting more energy from each drop of fuel. This efficiency advantage becomes particularly noticeable during heavy workloads, where diesel-powered excavators typically consume 20-30% less fuel than their gasoline counterparts performing the same tasks.

Can a diesel fuel pump be used with gasoline?

No, a diesel fuel pump cannot be safely or effectively used with gasoline in an excavator. There are several critical reasons for this:

Gasoline and diesel have different viscosity levels, and diesel pumps are designed to handle the thicker consistency of diesel fuel. Gasoline's lower viscosity would cause lubrication issues, leading to rapid wear and potential pump failure.

The much higher pressure of diesel pumps would atomize gasoline improperly, causing inefficient combustion, engine damage, and potentially dangerous detonation.

Additionally, the materials used in diesel pumps may not be compatible with gasoline, leading to corrosion or degradation of components.

Converting a diesel pump to work with gasoline would require extensive modifications to the entire fuel system, making it impractical and cost-prohibitive compared to using the correct pump for each fuel type.

Conclusion

While gasoline and diesel fuel pumps in excavators share the basic function of delivering fuel to the engine, their designs, operating pressures, and fuel delivery methods are fundamentally different. These differences reflect the distinct combustion processes of gasoline and diesel engines.

Diesel pumps, with their high-pressure systems, complement the efficiency of diesel engines, making them the preferred choice for most heavy-duty excavator applications. Importantly, the two pump types are not interchangeable due to differences in fuel properties and system requirements.

How can I tell if my turbocharger is smoking?

How to increase the service life of turbocharger?

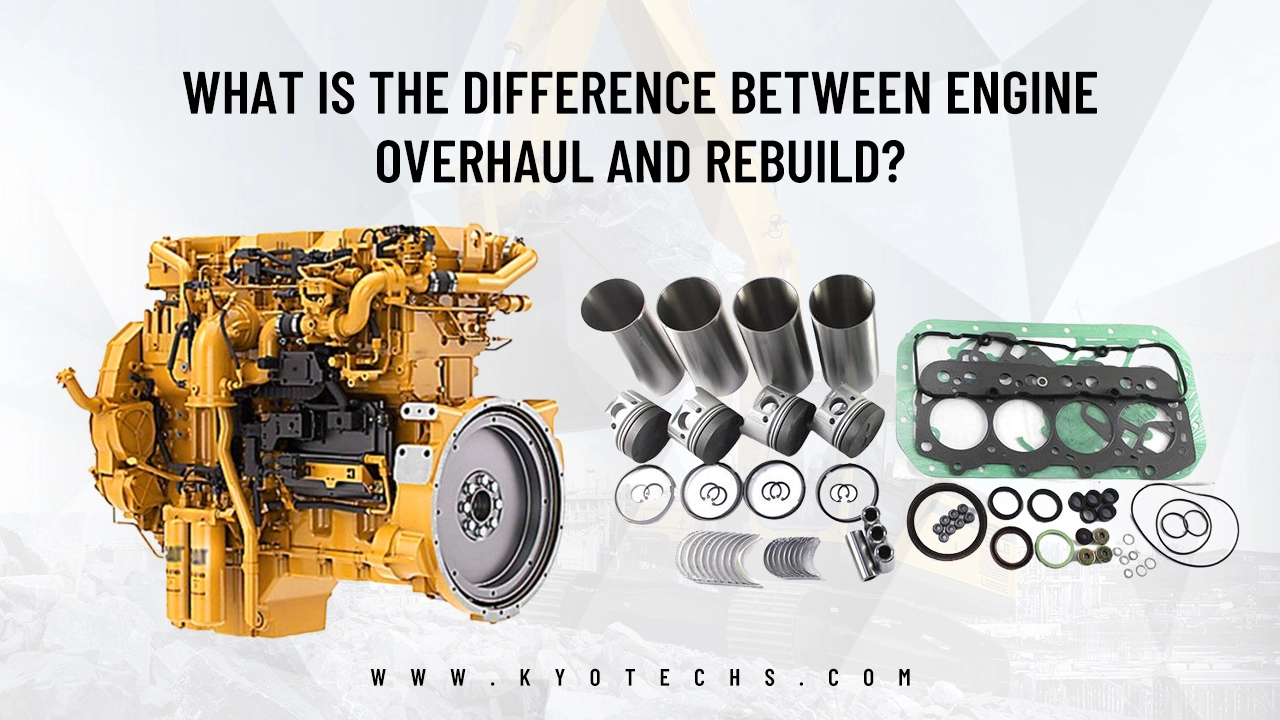

What is the difference between engine overhaul and rebuild?

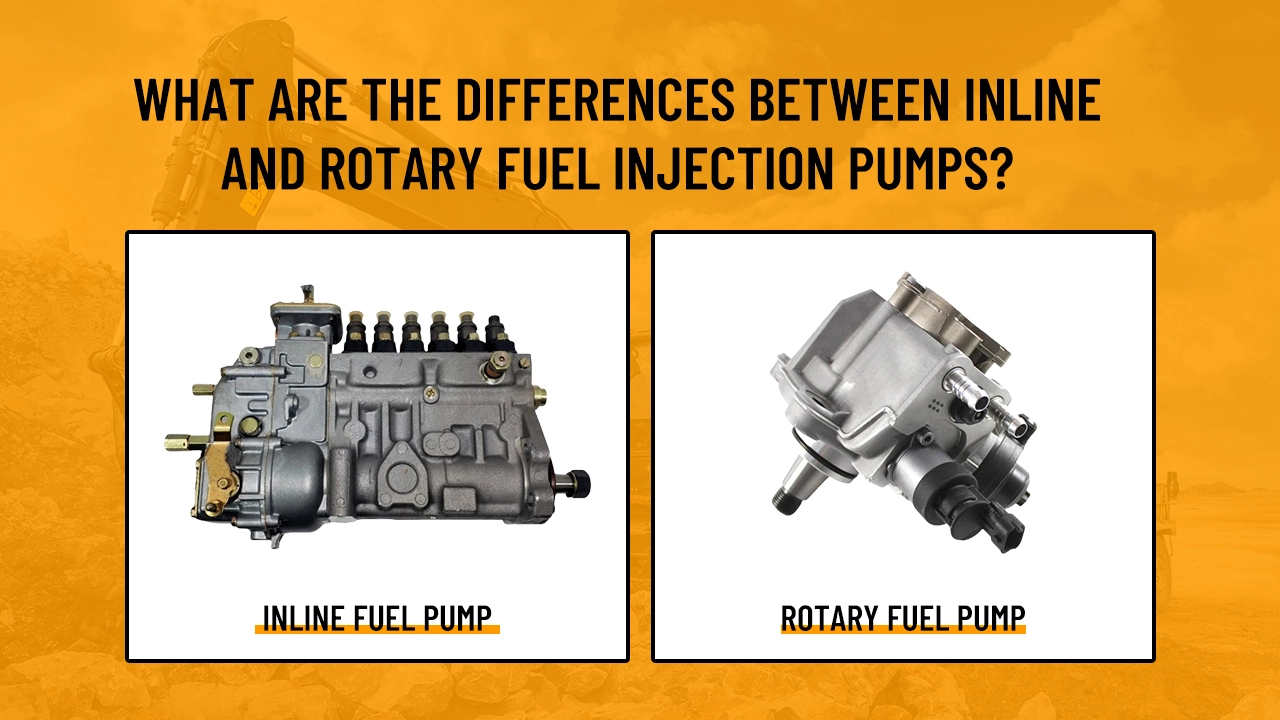

What are the differences between inline and rotary fuel injection pumps?

FAQS

What parts you have?

We are specialized in excavator spare parts, such as travel motor gearbox assy & parts, swing gearbox motor assy & parts, and hydraulic pump motor assy and spare parts. If any are needed, we can also supply them as per your requirements.

Do you only sell or repair?

Yes, we sell parts and have a repair team to offer support.

1. Software solution.

A. ECU & Monitor Reprogram

B. DPF Program Solution

C. Software refit

2. Engine Rebuild & Testing

Maintenance Team Support

A. ET for Caterpillar Diagnosis

B. Inline 6 for Cummins/Komatsu/Hyundai Diagnosis

C. IDSS for Hitachi/Isuzu/Case/Sany/Sumitomo/JCB/XCMG/Isuzu Truck Diagnosis

D. DX2/NEXIQ for Kobelco/Hino truck Diagnosis

E. Vocom for Volvo/Volvo truck/Penta Diagnosis

F. DST-i for KUBOTA DENSO Diagnosis

3. hydraulic Remanufacture & Testing

A. Offer new or rebuilt hydraulic pump & motor

B. Control valve & main pump repair & rebuild knowledge

C. Offer stable and cheap hydraulic test machines

D. All rebuild valves, pumps, and motors offer testing video for cilent

If i don'thave part number, can you check for me?

Yes, excavator model, old photos, and size are also available to confirm the correct parts you need.

Which shipping term you can supply?

By sea, air or by express ( DHL, Fedex, TNT, UPS, EMS)

How long does it take to my address?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs