Doosan Excavator Parts: FAQs & Expert Insights | Kyotechs

- What Are the Most Common Doosan Excavator Parts That Need Replacement?

- How Do I Ensure Compatibility When Buying Doosan Excavator Parts?

- Where Can I Buy Genuine Doosan Excavator Parts?

- How Can I Extend the Lifespan of My Doosan Excavator Parts?

- What Are the Signs That My Doosan Excavator Parts Need Replacement?

- Why Should I Choose Genuine Doosan Excavator Parts Over Aftermarket Options?

# Doosan Excavator Parts: Your Top Questions Answered

When it comes to maintaining and repairing Doosan excavators, understanding the right parts and their functionality is crucial. Whether you're a contractor, equipment manager, or DIY enthusiast, knowing where to source genuine Doosan excavator parts and how to ensure their compatibility can save you time and money. Below, we’ve compiled the most frequently asked questions about Doosan excavator parts, along with expert insights to help you make informed decisions.

What Are the Most Common Doosan Excavator Parts That Need Replacement?

Doosan excavators are built for durability, but certain parts are more prone to wear and tear due to heavy usage. The most commonly replaced parts include:

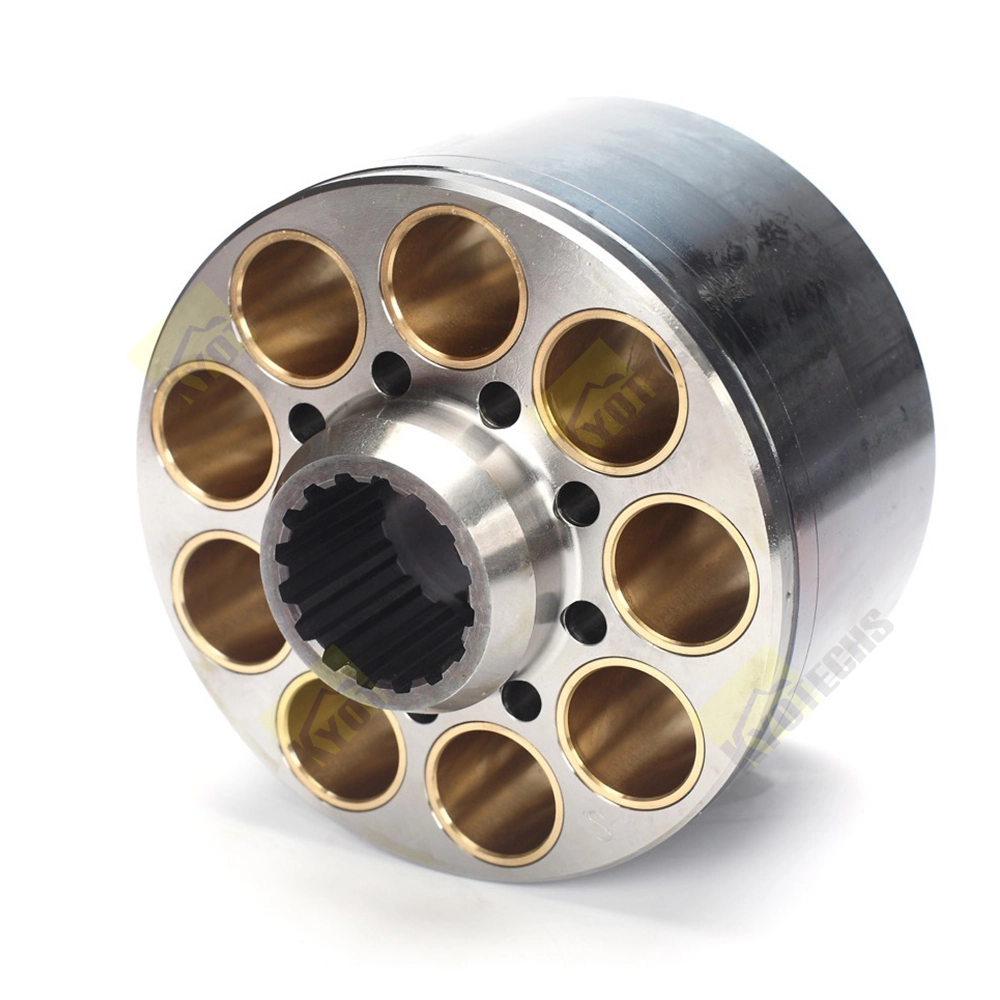

- Hydraulic Filters: Essential for maintaining hydraulic system efficiency.

- Undercarriage Components: Tracks, rollers, and idlers often wear out due to constant friction.

- Bucket Teeth and Cutting Edges: These are subject to abrasion and impact during digging.

- Engine Parts: Air filters, fuel filters, and belts require regular replacement to ensure optimal performance.

- Seals and Gaskets: Prevent leaks and maintain system integrity.

Regular inspection and timely replacement of these parts can extend the lifespan of your Doosan excavator.

How Do I Ensure Compatibility When Buying Doosan Excavator Parts?

Compatibility is critical when purchasing replacement parts for your Doosan excavator. Here’s how to ensure you get the right fit:

1. Check the Model and Serial Number: Always refer to your excavator’s model and serial number to identify the correct parts.

2. Consult the Parts Manual: Doosan provides detailed parts manuals that list compatible components for each model.

3. Buy Genuine Parts: Genuine Doosan excavator parts are designed specifically for your machine, ensuring perfect compatibility and performance.

4. Work with Reputable Suppliers: Trusted suppliers like Kyotechs can help you verify compatibility and provide expert guidance.

Using incompatible parts can lead to equipment failure, increased downtime, and higher repair costs.

Where Can I Buy Genuine Doosan Excavator Parts?

Genuine Doosan excavator parts are available through authorized dealers and trusted online suppliers. Here are your best options:

- Authorized Doosan Dealers: These dealers have direct access to genuine parts and can provide expert advice.

- Online Marketplaces: Reputable platforms like Kyotechs offer a wide range of Doosan excavator parts with detailed product descriptions and compatibility information.

- Local Equipment Suppliers: Some local suppliers stock genuine parts for popular Doosan models.

Always verify the authenticity of the parts and the credibility of the supplier before making a purchase.

How Can I Extend the Lifespan of My Doosan Excavator Parts?

Proper maintenance is key to extending the lifespan of your Doosan excavator parts. Follow these tips:

1. Regular Inspections: Check for signs of wear, leaks, or damage during routine maintenance.

2. Timely Replacements: Replace worn-out parts before they cause further damage to the system.

3. Use Genuine Parts: Genuine parts are designed to meet Doosan’s quality standards, ensuring better performance and longevity.

4. Follow the Maintenance Schedule: Adhere to the manufacturer’s recommended maintenance intervals for optimal results.

By taking these steps, you can minimize downtime and reduce long-term repair costs.

What Are the Signs That My Doosan Excavator Parts Need Replacement?

Recognizing the signs of failing parts can prevent costly breakdowns. Look out for these indicators:

- Reduced Performance: Slower operation or decreased digging power may signal worn-out hydraulic components.

- Unusual Noises: Grinding or knocking sounds often indicate issues with the undercarriage or engine.

- Leaks: Hydraulic fluid or oil leaks are a clear sign that seals or gaskets need replacement.

- Excessive Vibration: This could point to problems with the tracks or other undercarriage components.

If you notice any of these signs, inspect the affected parts and replace them as needed.

Why Should I Choose Genuine Doosan Excavator Parts Over Aftermarket Options?

While aftermarket parts may seem cost-effective, genuine Doosan excavator parts offer several advantages:

- Perfect Fit: Designed specifically for Doosan machines, ensuring seamless integration.

- Superior Quality: Manufactured to meet Doosan’s rigorous standards for durability and performance.

- Warranty Protection: Genuine parts often come with a warranty, providing peace of mind.

- Long-Term Savings: Higher quality means fewer replacements and repairs over time.

Investing in genuine parts is a smart choice for maintaining the reliability and efficiency of your Doosan excavator.

By addressing these common questions, we hope to provide valuable insights into sourcing, maintaining, and replacing Doosan excavator parts. For genuine parts and expert advice, trust Kyotechs to keep your equipment running at its best.

Kyotechs best professional Hyundai excavator parts Manufacturers and supplier brand

Enhancing Your Excavator Performance with Quality Hydraulic Parts

Kyotechs best professional Daewoo excavator parts Manufacturers and supplier brand

Enhance Your 1175Excavator With Kyotechs Rubber Parts Foot

FAQS

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

How to check the coolant level of the excavator?

When the engine is cold, check the coolant level through the level gauge of the coolant tank and add coolant if necessary.

What kind of battery is used in the excavator? Why?

The batteries we use are all lead-acid batteries for starting. Because this type of battery has the characteristics of large starting current and can meet the power supply requirements of the starter motor.

Why is the hydraulic pump pressure insufficient during excavation?

Possible low hydraulic oil level, clogged filter, internal wear, or hydraulic line leakage. Solution: Check oil level and refill, clean or replace filter, inspect and repair leaks, check and replace worn parts.

Why choose Kyotechs?

1. Kyotechs, Focus on the machinery industry over 20 years, have abundant experience and sound reputation in the field. support the full range of excavator accessories.

2. kyotechs offer Maintenance service: repair and testing for monitor ECU controller software; Engine start testing, remanufacture and repaint; Hydraulic pump refit, etc.

3. 100% quality guaranteed; Kyotechs offers different quality requirements for excavator parts. new and used genuine parts, OEM parts made in China, Japan, Korea. main parts normal operation running at least 3-5 years. Use Kyotechs parts; few worries!

4. Small orders and sample orders are acceptable; large quantities and price negotiations.

5. Quick delivery time: order before 4:00 p.m. and ship out on the same day.

Excavator Spare Parts 4M50 Engine Assembly For Sany SY215

Excavator parts 708-2J-00030 Hydraulic Main Pump For Komatsu PC500LC-10R

Excavator Spare Parts YB60001906 Travel Gearbox For Hitachi EX1200-7 EX1200-6

Excavator parts 21P-60-K1502 Hydraulic Main Pump For Komatsu PC150LC-6K

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs