Kyotechs 3779082 - Efficiency and Innovation for Modern Living

Introducing the Kyotechs 3779082, a piece of cutting-edge technology designed to elevate your daily experience. This innovative product epitomizes efficiency, reliability, and the commitment to quality that Kyotechs is renowned for. With the Kyotechs 3779082, you're not just purchasing a product; you're investing in a promise of exceptional performance and user satisfaction.

The Kyotechs 3779082 is engineered with the user in mind, ensuring ease of use and seamless integration into your routine. Whether you are a tech enthusiast or someone seeking to simplify life, this product's practicality and value are unmatched. Its robust build and top-tier components guarantee long-term durability, helping you achieve your goals without a hitch.

Value-driven and user-centered, the Kyotechs 3779082 provides exceptional support and assurance, making you feel truly valued as a consumer. The ergonomic design and intuitive interface mean that you can instantly benefit from its features, enhancing productivity and efficiency in every aspect of your routine.

Kyotechs, as a brand, is committed to pushing the boundaries of innovation while focusing on sustainability and customer satisfaction. The Kyotechs 3779082 reflects this ethos, offering you not just a product but a partner in your journey towards a more efficient and fulfilling lifestyle.

With Kyotechs 3779082, embrace a future where technology is uncomplicated, reliable, and built around you. Explore the potential of this exceptional product and experience firsthand how Kyotechs cares for and values its customers.

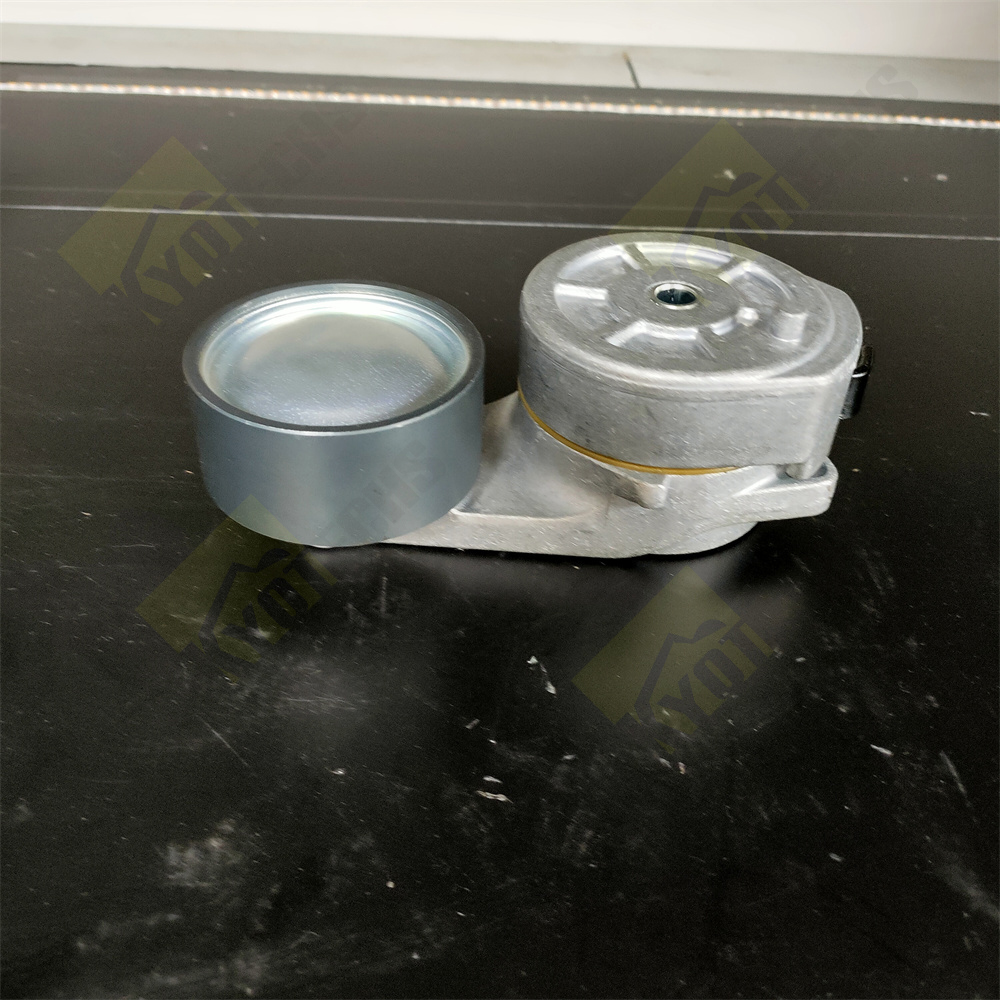

Product Image

Advantages

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

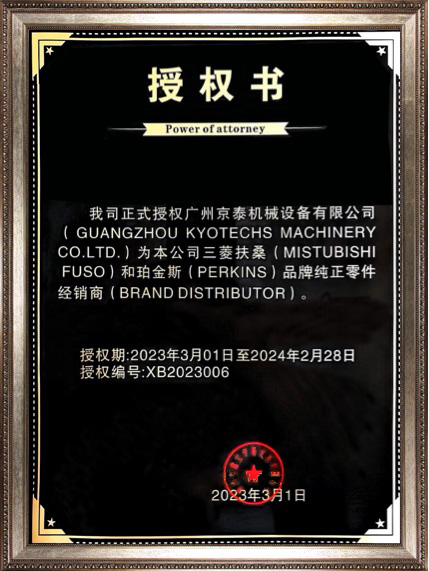

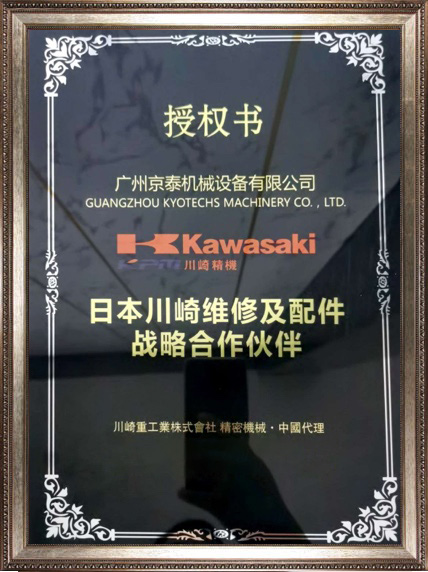

Our Certifications

Perkins

TUV

KAWASAKI

Q&A

What are the reasons for the excavator crawler chain off?

1. Chain off caused by tension cylinder failure

At this time, you should check whether you have forgotten to butter the tension cylinder and see if there is any oil leakage in the tension cylinder.

2. Chain off caused by severe wear of the crawler

If used for a long time, the crawler will definitely be worn, and the wear of the chain ribs, chain barrels and other parts on the crawler will also cause the crawler chain off.

3. Chain off caused by wear of the chain guard

Now almost all excavator crawlers have chain guards, and chain guards can play a very important role in preventing chain off, so it is also very important to check whether the chain guard is worn.

4. Chain off caused by wear of the drive motor ring gear

For the drive motor ring gear, if it is severely worn, we need to replace it, which is also an important reason for the excavator chain off.

5. Chain off caused by damage to the sprocket wheel

Generally speaking, oil leakage of the sprocket wheel oil seal of the excavator will cause severe wear of the sprocket wheel, which will cause the crawler chain off. The public account Zhizao Daguan focuses on sharing relevant theoretical knowledge in the engineering machinery manufacturing industry.

6. Chain derailment caused by guide wheel damage

When checking the track guide wheel, check whether the screws on the guide wheel are missing or broken. Check whether the groove of the guide wheel is deformed.

What are the conditions for good starting performance of excavators?

- There must be enough starting speed. The high starting speed means less gas leakage in the cylinder, shorter heat transfer time of compressed air to the cylinder wall, less heat loss, and higher gas temperature and pressure at the end of compression. Generally, the speed is required to be above 100r/min.

2. The cylinder should have good sealing. This can further reduce the amount of leakage and ensure that the gas has sufficient combustion temperature and pressure at the end of compression. The compression pressure of the cylinder shall not be lower than 8_0_%_ of the standard value.

3. The engine is required to have appropriate clearance relative to the running parts and good lubrication.

4. The battery must have sufficient starting capacity and the technical condition of the starting circuit is normal.

5. The starting oil volume meets the requirements, the injection quality is good, and the injection advance angle meets the requirements.

6. Use fuel that meets the requirements

How to avoid the derailment (chaining) of the crawler chain of the excavator?

1. When walking on the construction site, please try to place the travel motor behind the walking to reduce the squeezing of the sprocket.

2. The continuous walking time of the machine cannot exceed 2 hours. The walking time on the construction site should be minimized. If necessary, it is recommended to walk after a short stop in the middle.

3. Avoid raised hard objects when walking to avoid stress concentration on the track chain.

4. Confirm the tightness of the crawler, adjust the crawler tighter in soft places such as soil, and adjust the crawler looser when walking on stones. It is not good to have a crawler that is too loose or too tight. Too loose will cause the crawler to derail easily, and too tight will cause the chain sleeve to wear too quickly.

5. Check whether there are foreign objects such as stones in the crawler frequently, and clean them if there are.

6. When working on a muddy construction site, it is necessary to frequently idle to discharge the soil deposited in the crawler.

7. Try to avoid the excavator turning in circles on the spot.

8. Regularly check the rail guard and the rail guard welded under the guide wheel.

What causes abnormal noise from the hydraulic pump during operation?

Possible air in the system, cavitation, internal component wear, or oil contamination. Solution: Bleed air from the system, check and fix cavitation sources, replace worn components, replace hydraulic oil.

If you have any questions about our goods or services, please feel free to contact us.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs