Kyotechs Caterpillar Hydraulic Pump: Fluid Type & Capacity

Overview

Kyotechs provides high-quality excavator parts for major brands, including Caterpillar. For hydraulic pumps, choosing the right fluid type and understanding system capacity are essential for long life, smooth operation, and reduced downtime. This guide gives clear, practical recommendations to help operators and technicians make confident decisions.

Hydraulic Fluid Type

Caterpillar hydraulic pumps perform best with high-quality anti-wear hydraulic oils that meet Caterpillar specifications. The commonly recommended fluids include Caterpillar HYDO Advanced or equivalent anti-wear hydraulic oils approved by Caterpillar. These oils protect pump components, reduce wear, and maintain stable performance across temperatures.

Simple guidance:

- Use anti-wear hydraulic oil that matches Caterpillar specs (e.g., HYDO Advanced equivalents).

- Choose viscosity based on ambient temperature: ISO VG 32 for cold climates, ISO VG 46 for moderate, ISO VG 68 for hot conditions—always confirm with your machine manual.

- Avoid mixing incompatible fluids; when changing fluid types, follow proper flushing procedures.

Hydraulic System Capacity

The hydraulic pump itself holds minimal fluid; total hydraulic system (reservoir) capacity is what matters for maintenance and refill. Typical Caterpillar excavator hydraulic fluid capacities vary by machine size:

- Mini excavators: ~10–40 liters

- Medium excavators: ~80–160 liters

- Large excavators: ~200–350 liters

These are general ranges. Always consult the specific Caterpillar model operator or service manual for exact reservoir and circuit capacities before topping up or servicing.

Why Choose Kyotechs

Trusted Parts & One-Stop Services

Established in 2009, Kyotechs supplies a full range of excavator parts across brands including Caterpillar. We offer one-stop hydraulic repair solutions, genuine-quality replacement parts, and clear technical support. Our goal is to help you get the right fluid, correct capacity, and professional service for reliable equipment performance.

Maintenance Tips

Regularly check fluid level, contamination, and viscosity. Replace filters and perform scheduled fluid analysis. When in doubt, contact Kyotechs for parts, repair advice, or service recommendations to keep your Caterpillar hydraulic pump running smoothly.

Advantages

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

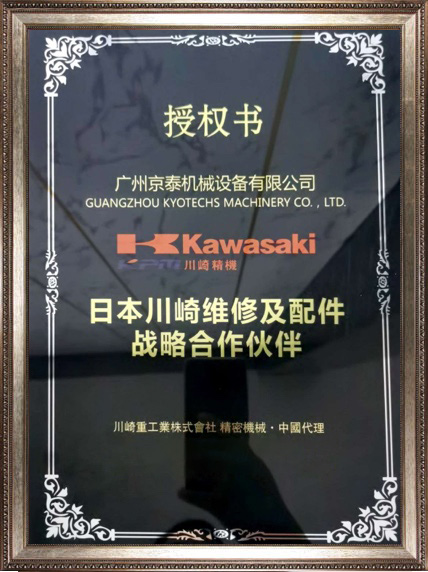

Certifications

TUV

Tongmyung

KAWASAKI

Question you may concern

When does the battery in use need to be recharged?

When the battery liquid specific gravity is lower than 1.15 or the single cell voltage is lower than 1.7V (V), or when changing seasons for maintenance, it should be removed for recharging and the liquid specific gravity should be adjusted. If it needs to be parked for a long time, it should be fully charged and stored, and recharged once a month. If it needs to be stored for a long time, it should be fully charged, all the liquid should be poured out, and the filling port should be sealed for storage. When it needs to be used, re-add the electrolyte that meets the requirements.

What causes hydraulic pump cavitation?

Possible low hydraulic oil level, high oil viscosity, or restricted fluid flow.

Solution: Refill hydraulic oil, use correct viscosity oil, check and clear restricted areas.

Why does the exhaust pipe emit blue smoke?

When the engine replaces new piston rings, pistons or cylinder liners, due to the initial poor running-in, it is easy for the engine oil to enter the combustion chamber and burn, producing blue smoke. This phenomenon can generally be gradually eliminated after running for 8-10 hours.

(1) The oil level in the oil pan is too high.

(2) The engine oil in the air filter leaks into the combustion chamber from the intake pipe and burns.

(3) The piston ring is bonded to the piston ring groove by carbon deposits, causing the engine oil to leak into the cylinder and burn.

(4) The piston ring is excessively worn, or when several piston rings are installed, the opening gap has been matched.

(5) The matching clearance between the piston and the cylinder liner is too large.

(6) The piston ring is not elastic enough.

Why should I check and replace the fuel filter?

Regularly checking and replacing the fuel filter can prevent impurities from entering the fuel system, ensure fuel cleanliness and extend the life of the engine.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs