Kyotechs Caterpillar Hydraulic Pump — Installation Guide & Benefits

Overview

This Kyotechs Caterpillar hydraulic pump installation guide provides clear, practical steps to fit and commission your excavator pump. Written for technicians and operators, it avoids heavy jargon and focuses on safety, reliability and long-term performance.

About Kyotechs

Kyotechs, established in 2009, supplies a full range of excavator parts including hydraulic pumps, engines, control valves, cylinders and more. We support brands like Caterpillar, Komatsu, Hitachi and Volvo, and offer One-Stop Hydraulic Repair and Engine Repair solutions.

Installation Steps

1. Preparation

- Park machine on level ground and secure it. Disconnect battery and relieve hydraulic pressure.

- Clean work area. Inspect mounting surfaces, drive couplings and hoses for wear.

- Confirm pump model and compatibility with Caterpillar specifications.

2. Mounting the Pump

- Use correct gaskets and torque values. Align pump shaft carefully to avoid coupling stress.

- Install mounting bolts in sequence and torque to manufacturer specs to prevent leaks and misalignment.

3. Hydraulic Connections

- Install suction and return lines with new filters. Ensure hoses are clean and free of debris.

- Use correct fittings and sealants recommended for Caterpillar systems. Avoid over-tightening.

4. Priming & Testing

- Prime pump according to instructions: fill with hydraulic fluid and rotate drive gently to remove air.

- Start engine at low idle and check for leaks, unusual noise, or vibration. Monitor pressure and temperature during initial run.

Maintenance & Tips

Change filters regularly, use recommended hydraulic oil, and keep the cooling system clear. Schedule periodic inspections to catch wear early. Proper installation and maintenance extend pump life and reduce downtime.

Why Choose Kyotechs

Our Caterpillar-compatible pumps offer reliable performance, strict quality checks and expert support. As a one-stop supplier, we deliver parts, repair solutions and technical guidance to get your excavator back to work quickly.

Support & Warranty

Contact Kyotechs for installation help, troubleshooting, or claims. We value your equipment uptime and provide responsive service and warranty options tailored to hydraulic repair needs.

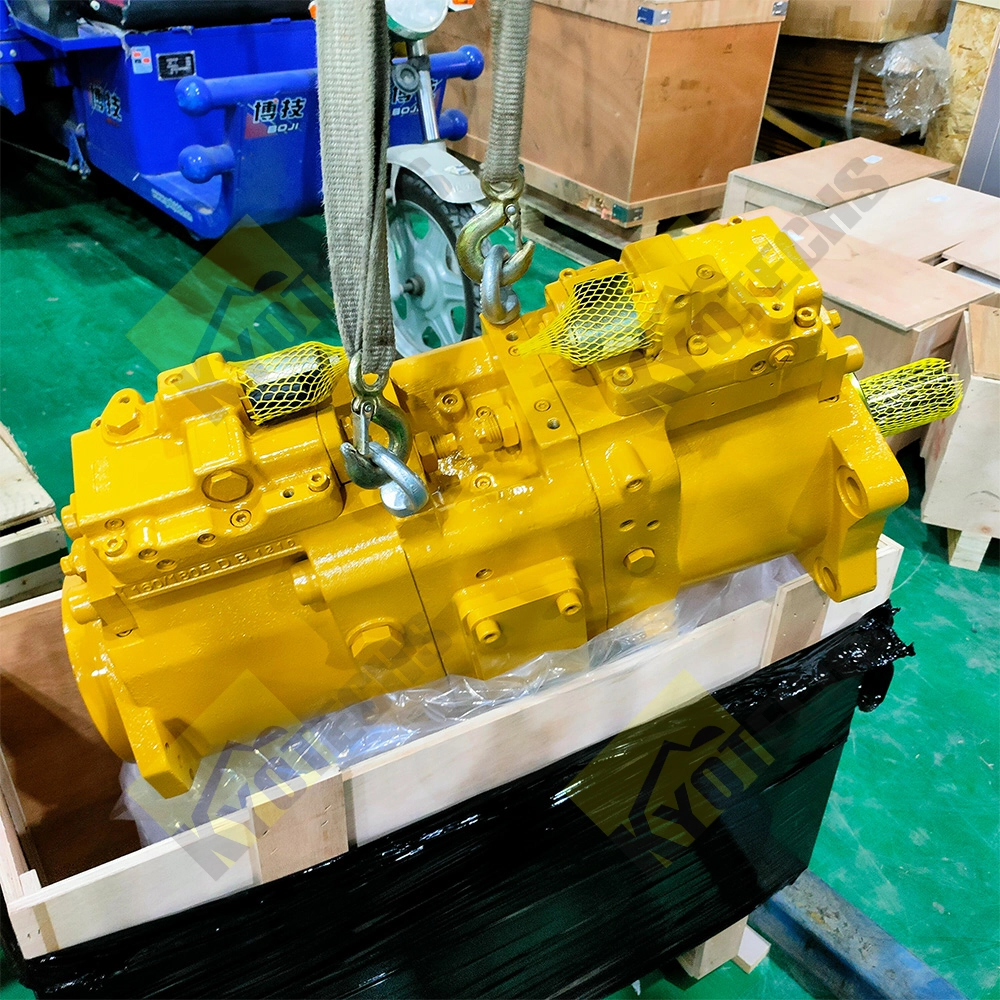

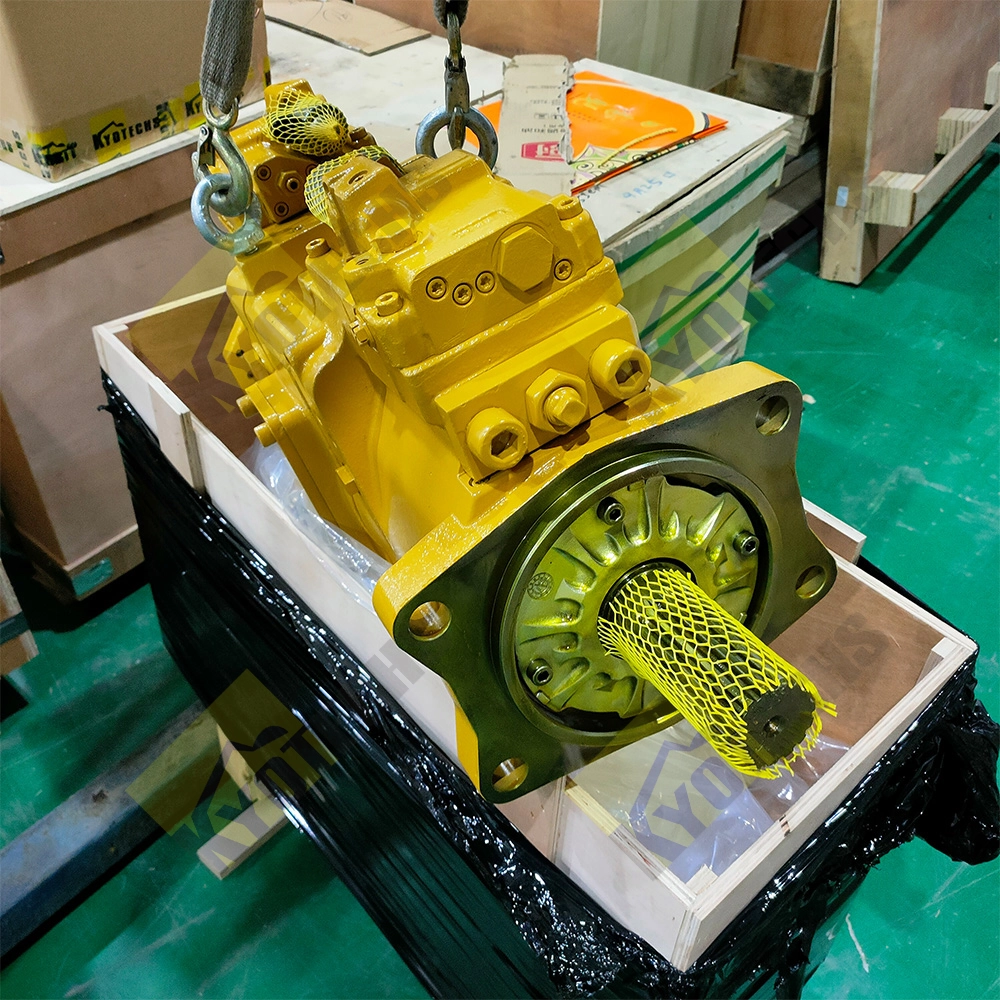

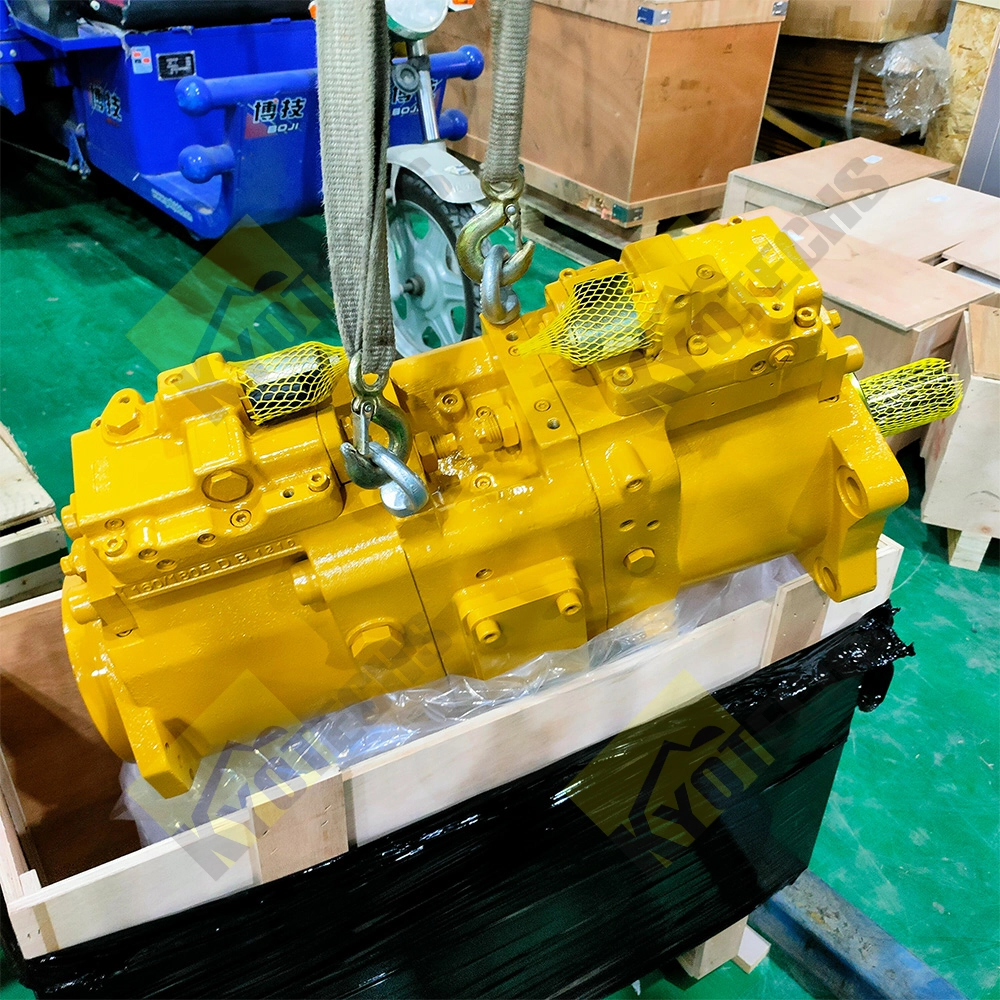

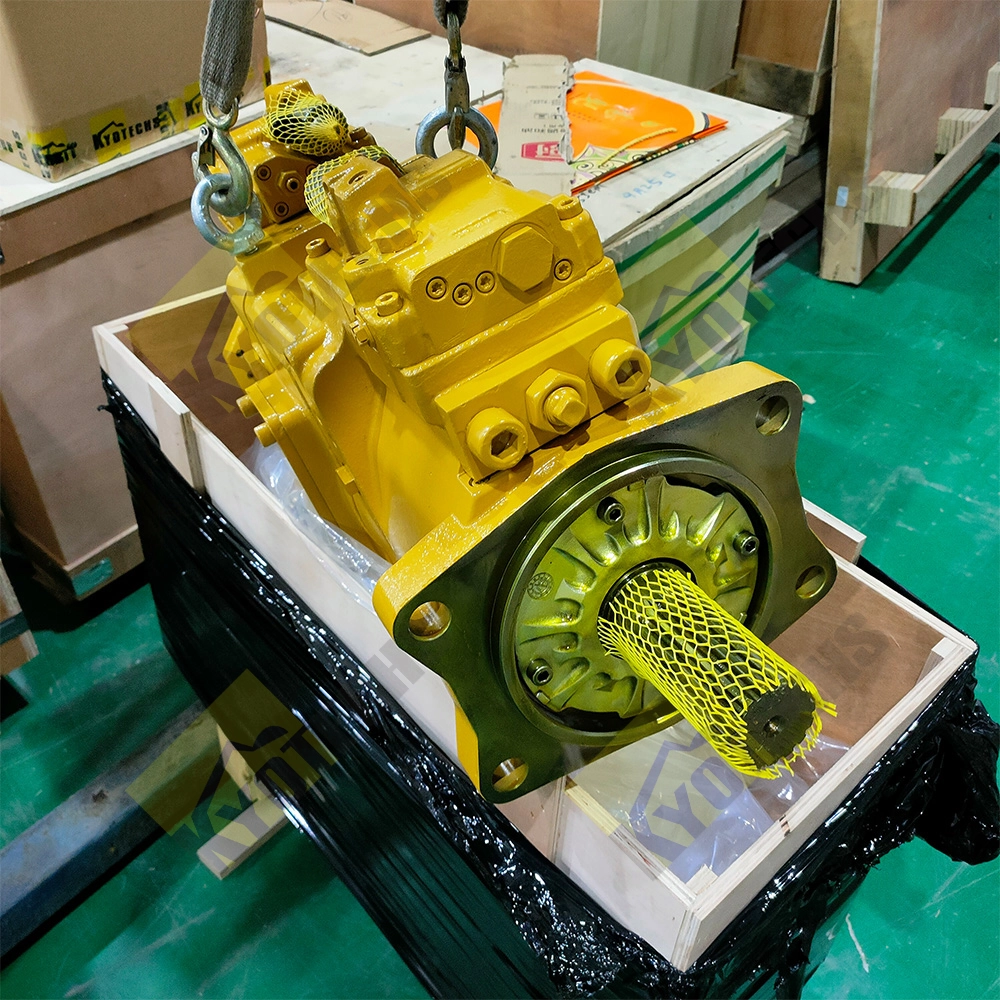

Product Image

Advantages

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

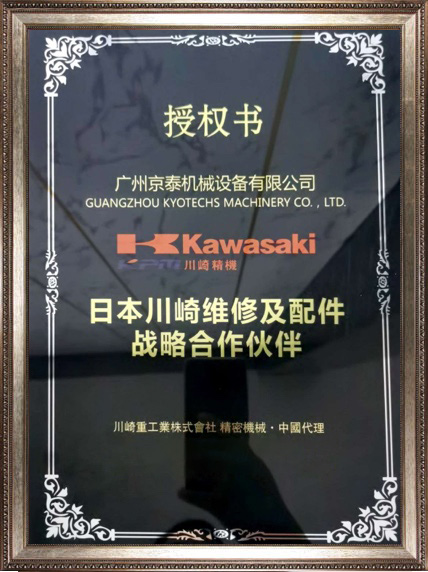

Certifications

TUV

Cummins BETT & INSITE

KAWASAKI

Frequently Asked Questions

How to troubleshoot the excavator's swing system?

Swing system issues are usually related to the hydraulic motor, swing gears, or control valves. First, check the operation of the hydraulic motor, inspect the gears for wear, and ensure the control valves are working properly. Replace faulty parts as needed.

How to ensure the excavator starts normally after long-term storage?

Before long-term storage, perform a thorough inspection and maintenance, drain fuel and hydraulic oil, lubricate all parts, start the engine periodically to run the system, and ensure all systems operate correctly.

What are the conditions for good starting performance of excavators?

- There must be enough starting speed. The high starting speed means less gas leakage in the cylinder, shorter heat transfer time of compressed air to the cylinder wall, less heat loss, and higher gas temperature and pressure at the end of compression. Generally, the speed is required to be above 100r/min.

2. The cylinder should have good sealing. This can further reduce the amount of leakage and ensure that the gas has sufficient combustion temperature and pressure at the end of compression. The compression pressure of the cylinder shall not be lower than 8_0_%_ of the standard value.

3. The engine is required to have appropriate clearance relative to the running parts and good lubrication.

4. The battery must have sufficient starting capacity and the technical condition of the starting circuit is normal.

5. The starting oil volume meets the requirements, the injection quality is good, and the injection advance angle meets the requirements.

6. Use fuel that meets the requirements

How to repair damaged hydraulic pump impellers?

Possible cavitation or debris in the oil.

Solution: Replace damaged impellers, prevent cavitation, filter oil.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs