Kyotechs Caterpillar Hydraulic Pump Troubleshooting & Parts

Reliable Caterpillar Hydraulic Pump Troubleshooting by Kyotechs

When a Caterpillar hydraulic pump shows symptoms like low pressure, unusual noise, overheating, or slow boom movement, quick and accurate troubleshooting is essential to avoid costly downtime. Kyotechs, established in 2009, offers experienced support, quality parts, and complete repair solutions for Caterpillar pumps and related hydraulic systems.

Common Symptoms and Quick Checks

- Low hydraulic pressure — check fluid level, filter condition, and hose leaks.

- Unusual noise or whining — inspect pump bearings, shaft alignment, and fluid aeration.

- Overheating — verify fluid viscosity, cooling system, and excessive internal leakage.

- Slow actuator movement — confirm control valve settings, contamination, or worn pump components.

Simple Troubleshooting Steps

- Start with visual inspection: hoses, fittings, and external leaks.

- Check hydraulic fluid: level, color, and contamination.

- Monitor pressure and temperature with gauges to isolate the issue.

- Swap or test filters and hoses to rule out blockages.

- If symptoms persist, consider pump bench testing or professional diagnostics.

Why Choose Kyotechs for Caterpillar Pump Repairs

Kyotechs supplies a full range of excavator parts, including hydraulic pumps, motors, control valves, and seal kits. Our advantages:

- Years of industry experience since 2009 and broad parts coverage for Caterpillar and other major brands.

- One-Stop Hydraulic Repair Solution: diagnostics, repair, parts replacement, and test services.

- High-quality components and remanufactured options to balance cost and reliability.

- Clear troubleshooting guidance and fast shipping to minimize equipment downtime.

Repair Options & Warranty

We offer repair, rebuild, and replacement services with tested components. All parts and services come with warranty coverage and post-repair support so you can operate with confidence.

Contact Kyotechs

For trustworthy Caterpillar hydraulic pump troubleshooting and parts, contact Kyotechs today. Our experts will guide you through quick checks, recommend the right parts, and arrange repairs to get your excavator back to work.

Product Images

Our Advantages

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Certifications

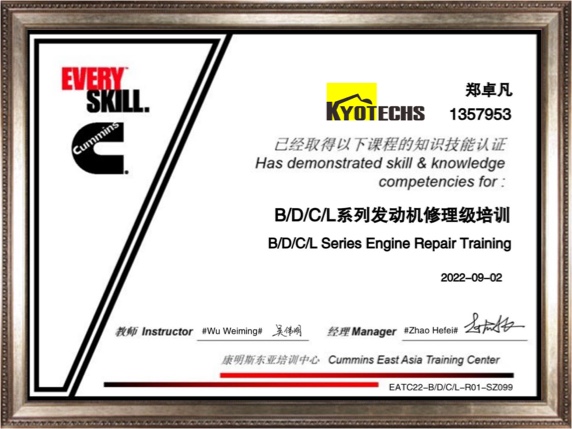

Cummins

Cummins REPAIR TRAINING

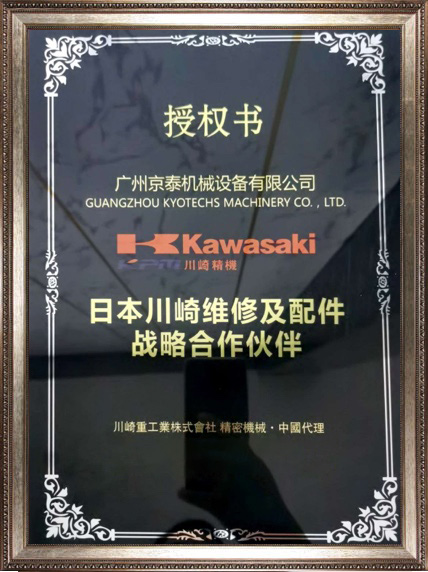

KAWASAKI

Question you may concern

How do you know if the perpendicularity between the ground gear plane and the bearing hole has changed?

It can only be found when assembling the gear pump, because the end face clearance is very small, generally around 0.05mm. If the perpendicularity between the end face and the bearing hole has changed, the gear shaft cannot move after the pump is assembled. If the locking screw is loosened a little, but it still does not turn smoothly, and the gear pump is disassembled and inspected, there are scratches on the end face. This is caused by the end face plane not being perpendicular to the bearing hole.

How to check if the hydraulic system of a track excavator is functioning properly?

To check if the hydraulic system is functioning properly, observe the color and viscosity of the hydraulic oil, check the oil level in the hydraulic tank, look for leaks in the lines and fittings, and test the output pressure of the hydraulic pump.

What liquid should be added to the battery (battery) used normally in the excavator after the liquid level drops? Why?

Distilled water should be added. Because the battery will generate heat during the charging and discharging process, the water will evaporate, and the specific gravity of the electrolyte will increase. After adding distilled water, the specific gravity of the electrolyte can be restored.

What steps should be taken if the excavator engine exhibits low oil pressure?

First, check the oil level and add oil if it's low. Inspect the oil filter for clogs or restrictions, and replace it if necessary. Check the oil pump for wear or damage, and test the oil pressure sensor for accuracy. If these components are functioning correctly, inspect the engine bearings and journals for excessive wear.

If you have any questions or concern, please contact us.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs