Kyotechs Hitachi Hydraulic Pump for Mini Excavator — Reliable Replacement

Product Overview

Kyotechs presents the Hitachi hydraulic pump for mini excavators — a durable, OEM-fit replacement designed to restore hydraulic power quickly and reliably. Built for smooth performance and long service life, this pump is ideal for contractors, rental fleets, and machine owners who need dependable operation with minimal downtime.

Why Choose Kyotechs Hitachi Hydraulic Pump?

Reliable Performance

This pump delivers steady flow and pressure to ensure your mini excavator runs with consistent digging and lifting power. It’s engineered to match Hitachi specifications to keep your machine performing like new.

Long-Lasting Durability

Manufactured from high-quality materials and precision tested, the pump resists wear and reduces the risk of premature failure. That means fewer replacements and lower long-term operating costs.

Easy Installation

Designed for straightforward fitment, the pump installs quickly with common tools. Clear compatibility makes replacement faster, so you can return the machine to work sooner.

Value and Support from Kyotechs

Founded in 2009, Kyotechs supplies a full range of excavator parts for brands like Hitachi, Sany, Kawasaki, Volvo, Hyundai, Doosan, Komatsu, Caterpillar, Case, and Kobelco. Our catalog includes engine assemblies, hydraulic pumps and motors, control valves, cylinders, cabins, electric parts, undercarriage components, mini excavators, pile drivers, and hammers.

One-Stop Repair Solutions

We provide One-Stop Excavator Software Solution, One-Stop Engine Repair solution, and One-Stop Hydraulic Repair Solution. When you choose Kyotechs, you get parts plus expert support to diagnose, repair, and maintain your equipment.

Buy with Confidence

We prioritize customer satisfaction. Each pump goes through quality checks and comes with support options to help with fitment and troubleshooting. Protect your equipment investment and reduce downtime with a reliable Hitachi hydraulic pump from Kyotechs.

Contact us for compatibility details, pricing, and lead times. Our team is ready to help you select the right pump and support your repair needs.

Picture Show

Advantages

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

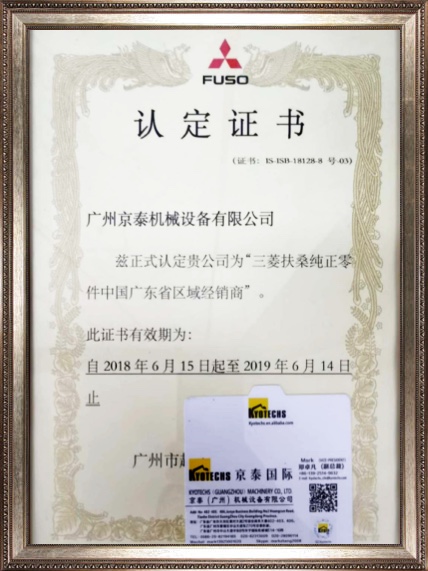

Our Certifications

MITSUBISHI FUSO

WYS

TUV

FAQ

Why should I check and replace the fuel filter?

Regularly checking and replacing the fuel filter can prevent impurities from entering the fuel system, ensure fuel cleanliness and extend the life of the engine.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

What liquid should be added to the battery (battery) used normally in the excavator after the liquid level drops? Why?

Distilled water should be added. Because the battery will generate heat during the charging and discharging process, the water will evaporate, and the specific gravity of the electrolyte will increase. After adding distilled water, the specific gravity of the electrolyte can be restored.

Which shipping term you can supply?

By sea, air or by express ( DHL, Fedex, TNT, UPS, EMS)

About other questions pls contact me directily.

Excavator Spare Parts 4M50 Engine Assembly For Sany SY215

Excavator parts 708-2J-00030 Hydraulic Main Pump For Komatsu PC500LC-10R

Excavator Spare Parts YB60001906 Travel Gearbox For Hitachi EX1200-7 EX1200-6

Excavator parts 21P-60-K1502 Hydraulic Main Pump For Komatsu PC150LC-6K

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs