Kyotechs Hitachi Hydraulic Pump Parts (Compatible Part Numbers)

Kyotechs Hitachi Hydraulic Pump Parts

Kyotechs offers durable, precision-engineered hydraulic pump parts compatible with common Hitachi hydraulic pump part numbers. Whether you need a full pump assembly or replacement components, our parts are designed to restore performance, reduce downtime, and lower operating costs for your excavator fleet.

Key Features

- High-quality materials and strict quality control for long service life

- Direct compatibility with Hitachi hydraulic pump part numbers to simplify ordering

- Complete range: pump assemblies, control valves, seals, and mounting kits

- Fast delivery and reliable packaging to protect parts in transit

- Technical support and guidance for fitment and installation

Compatibility and Part Numbers

Our hydraulic components are compatible with many Hitachi part numbers, helping you quickly find the right replacement. Examples include common Hitachi hydraulic pump part numbers such as 9198103, 9158599, and 4521493. If you have a different part number, provide it to our team and we will confirm fitment or suggest the correct alternative.

Why Kyotechs

Established in 2009, Kyotechs is a trusted supplier of excavator parts for brands including Hitachi, Sany, Kawasaki, Volvo, Komatsu and more. We offer One-Stop Hydraulic Repair Solution, One-Stop Engine Repair solution, and One-Stop Excavator Software Solution. Our approach focuses on practical value: reliable parts, clear compatibility, and service that minimizes equipment downtime. Customers benefit from transparent pricing, helpful pre-sale advice, and after-sale technical support.

How to Order

Send us your Hitachi hydraulic pump part number or equipment model. Our team will recommend the right Kyotechs part, provide a quote, and arrange fast shipping. Choose Kyotechs for dependable replacements that keep your excavators working efficiently.

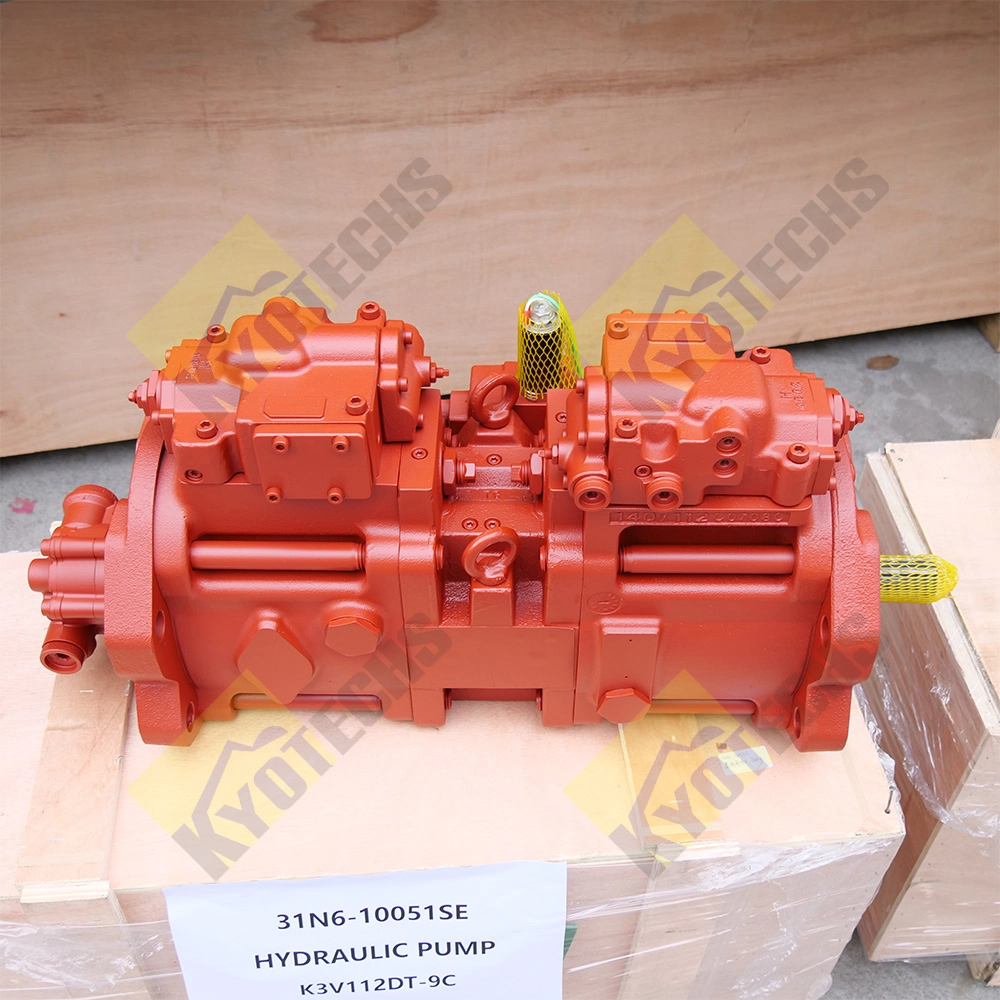

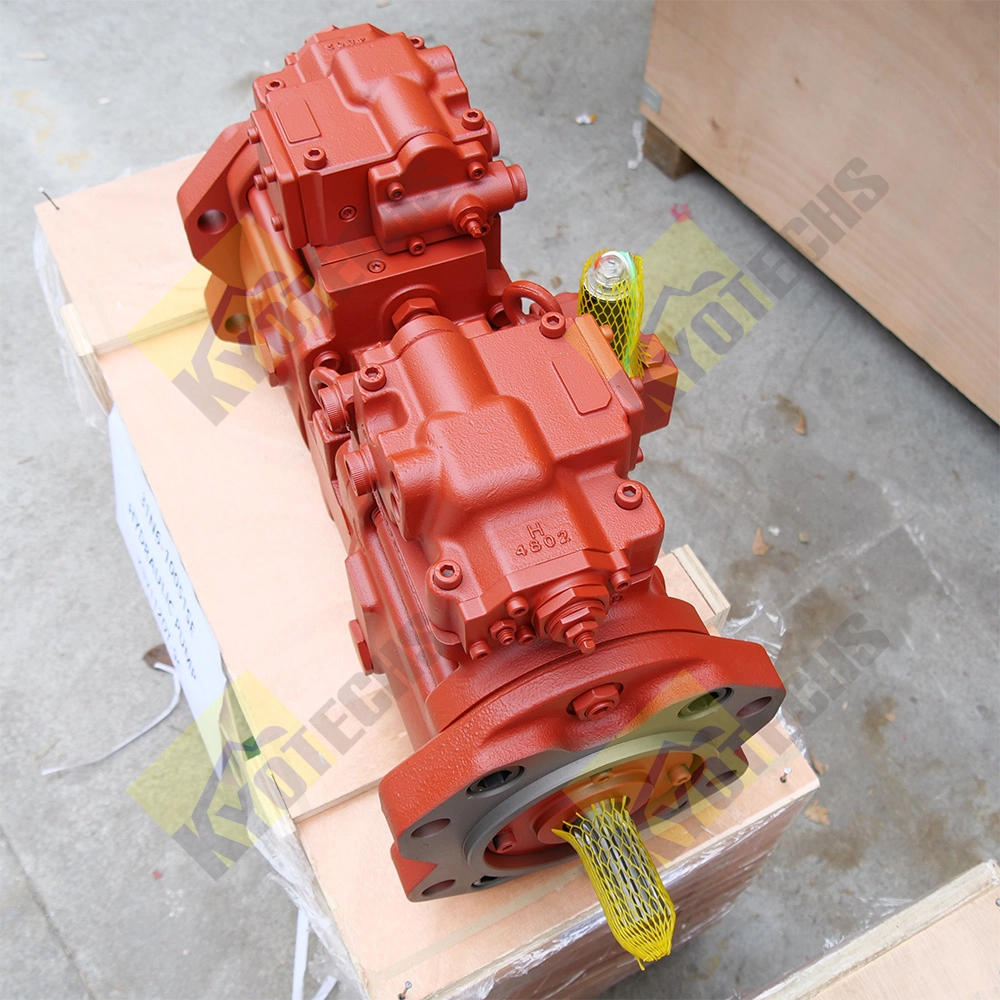

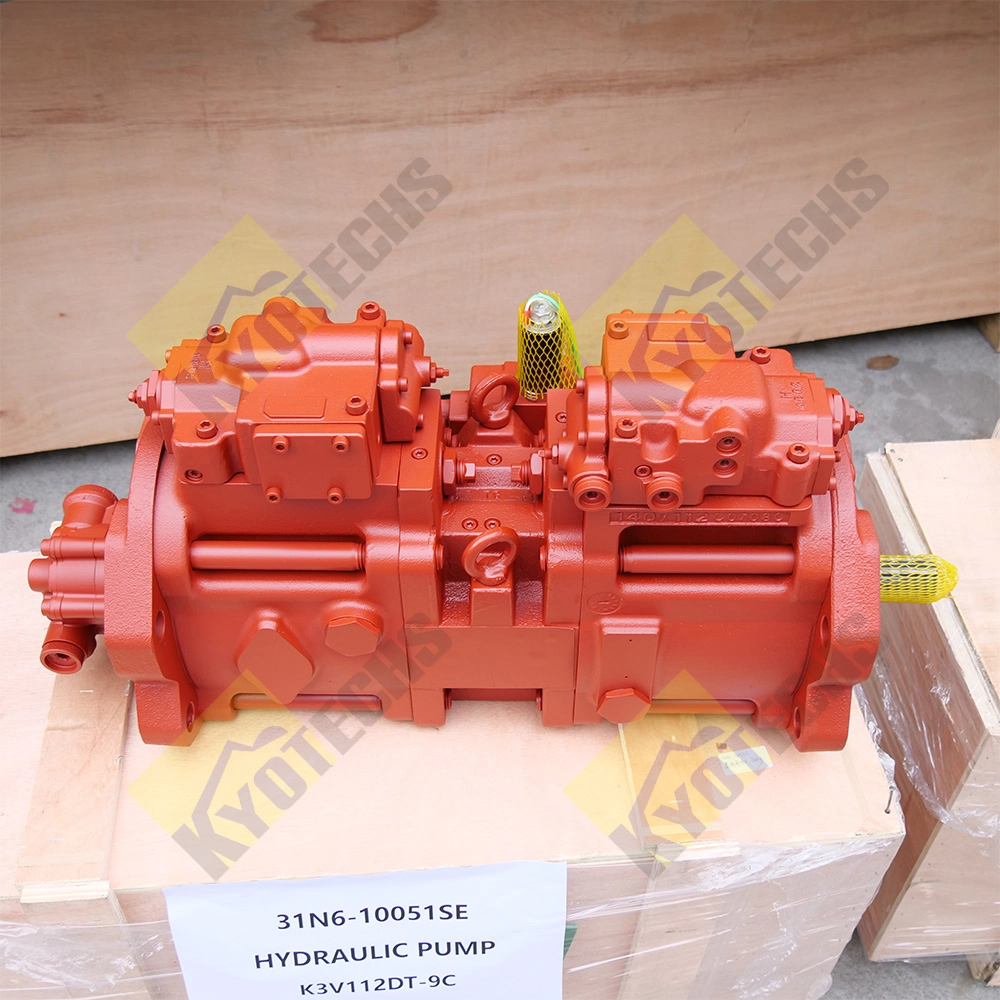

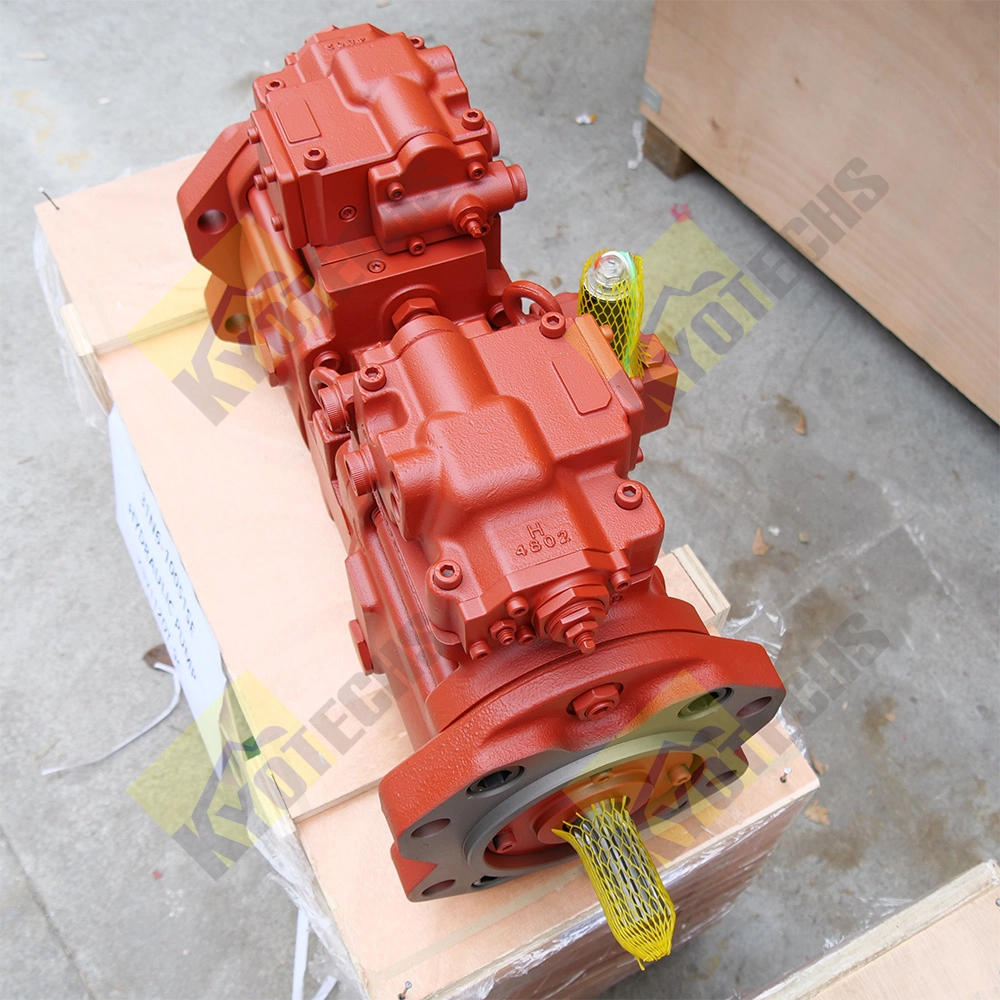

Picture Show

Our Advantages

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

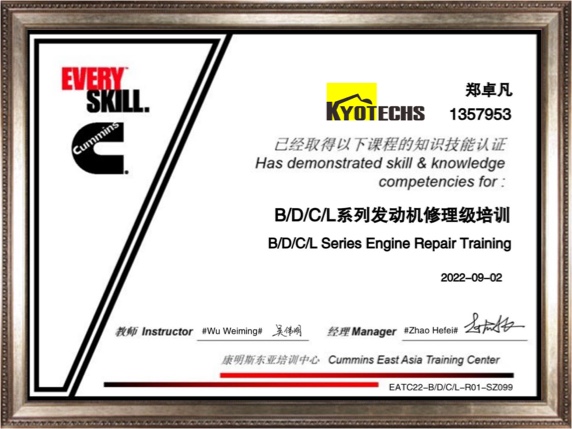

Certificate display

Cummins

WYS

Cummins REPAIR TRAINING

FAQ

Which shipping term you can supply?

By sea, air or by express ( DHL, Fedex, TNT, UPS, EMS)

How do you know if the perpendicularity between the ground gear plane and the bearing hole has changed?

It can only be found when assembling the gear pump, because the end face clearance is very small, generally around 0.05mm. If the perpendicularity between the end face and the bearing hole has changed, the gear shaft cannot move after the pump is assembled. If the locking screw is loosened a little, but it still does not turn smoothly, and the gear pump is disassembled and inspected, there are scratches on the end face. This is caused by the end face plane not being perpendicular to the bearing hole.

Why does the hydraulic system overheat quickly under low load?

Possible low hydraulic oil, clogged filter, high ambient temperature, or excessive load.

Solution: Refill hydraulic oil, clean or replace filter, ensure good ventilation, reduce system load.

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs