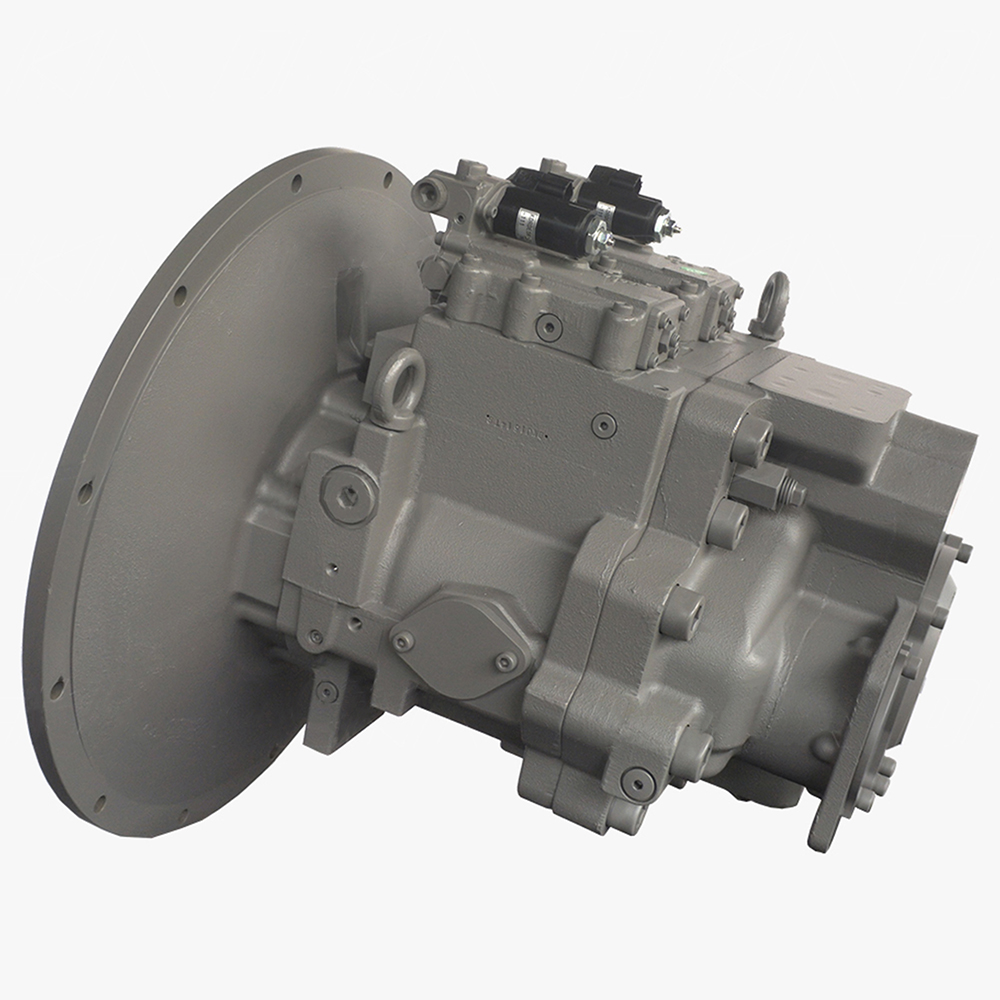

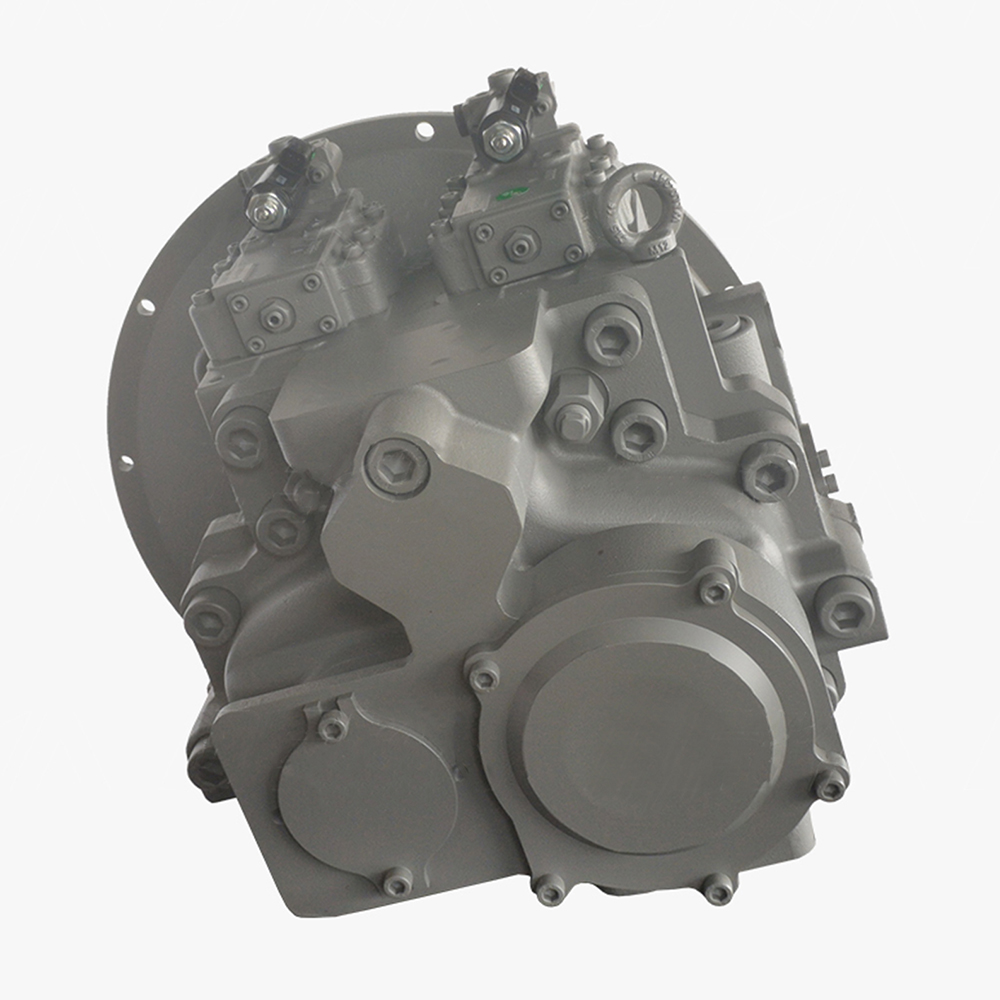

Kyotechs Hitachi Hydraulic Pump Rebuild Kit - Reliable Performance

Overview

The Kyotechs Hitachi hydraulic pump rebuild kit is designed to bring your excavator back to reliable hydraulic performance quickly and affordably. Kyotechs, established in 2009, supplies a full range of excavator parts and one-stop repair solutions. This rebuild kit includes all essential seals, gaskets, bearings, and wear components needed for common Hitachi pump overhauls.

Why Choose This Rebuild Kit?

Whether you're a workshop technician or a field engineer, this kit simplifies the repair process. Instead of sourcing individual parts, you get a matched set tested for fit and compatibility. That means less downtime, fewer installation issues, and a longer-lasting repair.

Practical Benefits

- Complete set: All seals, O-rings, bearings, and key wear parts included.

- Improved performance: Restores pump pressure and flow for smoother operation.

- Cost-effective: Cheaper than full pump replacement while delivering reliable results.

- Easy to install: Parts are organized and labeled to speed up rebuilds.

Quality and Support

Kyotechs maintains strict quality control and sources materials that meet industry standards. We back the rebuild kit with expert technical support—if you need guidance during installation, our team can assist. As part of our One-Stop Hydraulic Repair Solution, we also offer related components and upgrades to ensure a complete, durable repair.

Installation Tips

Before starting, clean the pump housing and inspect internal components for damage. Use the kit’s parts to replace worn seals and bearings, and follow torque and clearance specifications recommended for your Hitachi model. If wear is severe, consider replacing damaged components rather than reusing them.

Final Note

Kyotechs’ Hitachi hydraulic pump rebuild kit brings practical value: faster turnaround, dependable parts, and support from a supplier with deep excavator expertise. Keep your fleet running smoothly with a rebuild solution built for real-world work.

Detailed display

Our Advantages

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

Certificate display

Cummins

Cummins REPAIR TRAINING

Cummins BETT & INSITE

Question you may concern

What are the common causes of failure of hydraulic pump control valves?

Common causes of control valve failure include internal wear, seal damage, contamination and valve blockage.

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

What are the reasons for the excavator crawler chain off?

1. Chain off caused by tension cylinder failure

At this time, you should check whether you have forgotten to butter the tension cylinder and see if there is any oil leakage in the tension cylinder.

2. Chain off caused by severe wear of the crawler

If used for a long time, the crawler will definitely be worn, and the wear of the chain ribs, chain barrels and other parts on the crawler will also cause the crawler chain off.

3. Chain off caused by wear of the chain guard

Now almost all excavator crawlers have chain guards, and chain guards can play a very important role in preventing chain off, so it is also very important to check whether the chain guard is worn.

4. Chain off caused by wear of the drive motor ring gear

For the drive motor ring gear, if it is severely worn, we need to replace it, which is also an important reason for the excavator chain off.

5. Chain off caused by damage to the sprocket wheel

Generally speaking, oil leakage of the sprocket wheel oil seal of the excavator will cause severe wear of the sprocket wheel, which will cause the crawler chain off. The public account Zhizao Daguan focuses on sharing relevant theoretical knowledge in the engineering machinery manufacturing industry.

6. Chain derailment caused by guide wheel damage

When checking the track guide wheel, check whether the screws on the guide wheel are missing or broken. Check whether the groove of the guide wheel is deformed.

What are the reasons why the excavator can rotate when starting, but cannot start?

1.There is no oil in the fuel tank.

2.The fuel filter and oil-water separator are blocked.

3.The low-pressure oil circuit does not supply oil.

4.The injection pump does not pump oil.

5.There is air in the oil circuit.

6.The valve timing is misaligned. The opening time of the valve is not coordinated with the stroke of the piston in the cylinder. For example, when the piston makes a compression stroke in the cylinder, the intake and exhaust valves are open, and fresh air is driven out of the cylinder, so that there is no combustion gas in the cylinder and it cannot start.

7.The solenoid valve of the injection pump is broken and is in a closed state, and the diesel cannot enter the high-pressure chamber.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs