Kyotechs Hitachi Hydraulic Pump Spare Parts List

Product Overview

Kyotechs offers a comprehensive list of Hitachi hydraulic pump spare parts engineered for durability and fit. Whether you run Hitachi excavators in construction, mining, or rental fleets, our parts deliver consistent performance and reduce downtime. We combine quality components with technical support and repair solutions to give you a one-stop experience.

Hitachi Hydraulic Pump Spare Parts List

We stock both OEM-equivalent and high-quality aftermarket parts. Common spare parts include:

- Seal Kits — O-rings, shaft seals, gasket sets to stop leaks and restore pressure.

- Piston & Rotor Assemblies — Complete rotating groups for axial piston pumps.

- Swash Plates & Shoes — Wear components that control pump displacement.

- Valve Components — Relief valves, control valves, pressure regulators, and spools.

- Bearings & Bushings — Ensure smooth shaft rotation and long service life.

- Shafts & Couplings — Drive connections and replacement shafts.

- Filter & Suction Parts — Suction strainers and inlet components to protect the pump.

- Repair Kits — Combined kits for quick rebuilds (gaskets, seals, springs).

Compatible Models

Our parts cover a wide range of Hitachi pump models used on excavators. If you are unsure about fitment, provide the pump model number or part code and our team will confirm compatibility.

Why Choose Kyotechs

Established in 2009, Kyotechs specializes in excavator parts across major brands. We provide one-stop solutions for hydraulic repair, engine rebuilds, and parts sourcing. Each hydraulic part is inspected and tested; many come with warranty and technical support. Fast shipping and clear part identification help you get equipment back to work quickly.

Support & Service

Need help choosing the right part? Our technical team assists with part selection, installation tips, and repair guidance. We also offer repair kits and rebuild services to save time and cost.

Contact Kyotechs today with your Hitachi pump model or serial number and get the correct spare parts, fast service, and trusted support.

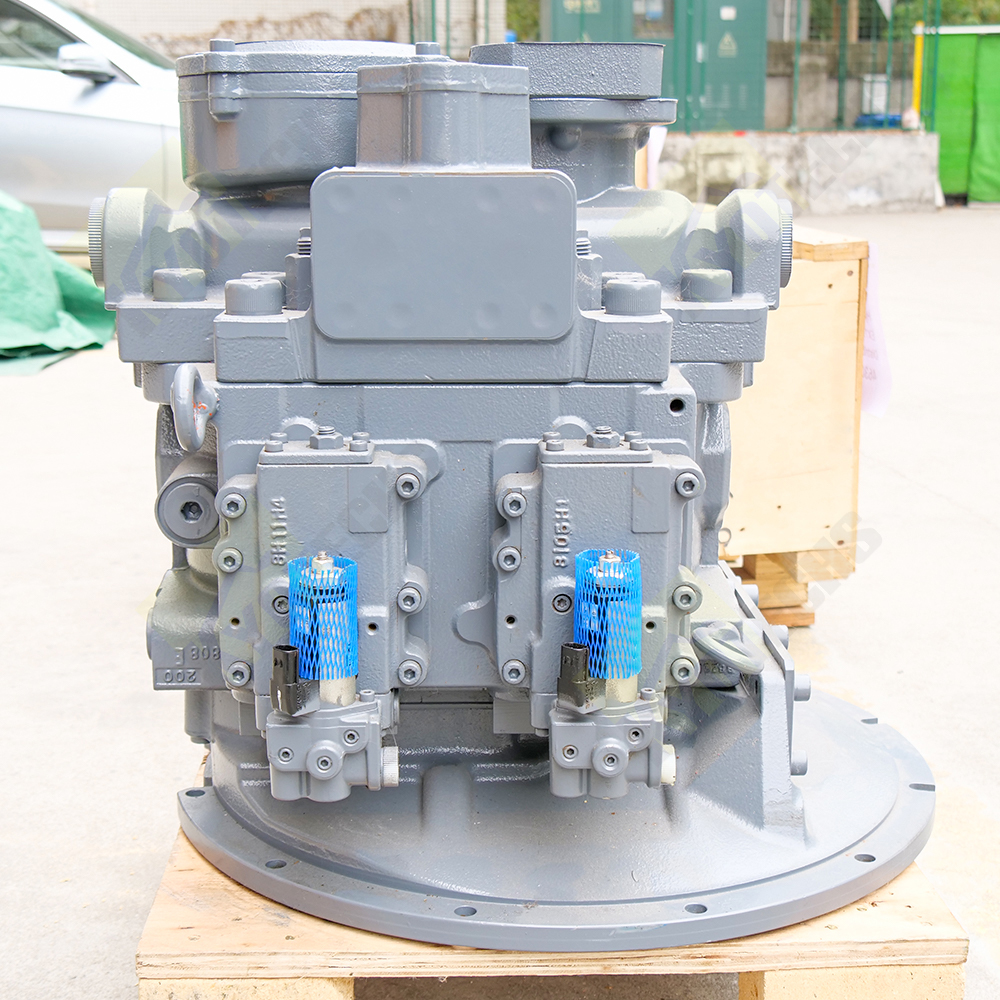

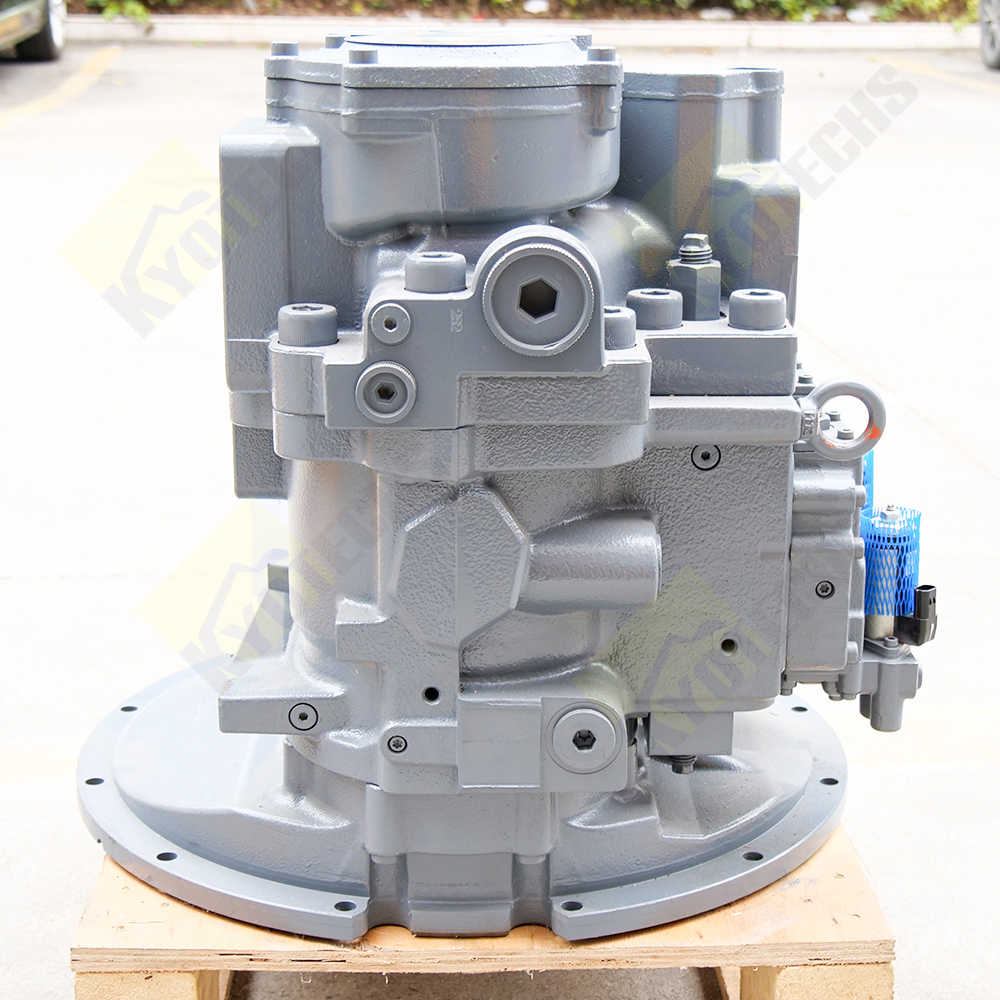

Product Image

Advantages

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

Our Certifications

Cummins REPAIR TRAINING

Cummins

HANDOK Hydraulic

Q&A

How do you troubleshoot abnormal exhaust smoke from an excavator engine?

Abnormal exhaust smoke can indicate various engine issues:

1. Black smoke:

Check for clogged air filters, over-fueling, or issues with the fuel injectors. Inspect the turbocharger (if equipped) for damage.

2. Blue smoke:

Indicates oil burning. Check for worn piston rings, valve seals, or a damaged turbocharger.

3. White smoke:

Can be caused by coolant entering the combustion chamber. Inspect the cylinder head gasket, cylinder head, and cooling system for leaks. Additionally, ensure the fuel injectors are operating correctly and not causing unburned fuel to emit as white smoke.

Digging powerlessness is one of the typical faults of excavators

Digging powerlessness can be divided into two situations: one is digging powerlessness, the engine does not hold back, and the load feels very light; the second is digging powerlessness, when the boom or dipper stick is extended to the bottom, the engine is seriously held back or even stalled.

①, digging powerlessness but the engine does not hold back. The magnitude of the digging force is determined by the output pressure of the main pump, and whether the engine holds back depends on the relationship between the oil pump absorption torque and the engine output torque. The engine does not hold back, indicating that the oil pump absorption torque is small and the engine load is light. If the working speed of the excavator is not obviously abnormal, the maximum output pressure of the main pump, that is, the system overflow pressure, should be checked in particular. If the overflow pressure measurement value is lower than the specified value, it indicates that the overload overflow valve setting value of the hydraulic circuit of the mechanism is incorrect, resulting in premature overflow of the mechanism and powerlessness. The machine can be adjusted by turning the adjustment screw.

②, digging powerlessness, engine holding back. The engine holding back indicates that the absorption torque of the oil pump is greater than the engine output torque, causing the engine to overload. This fault should first check whether the engine speed sensing system is normal, and the inspection method is similar to the engine inspection method described above. After the above detailed inspection and troubleshooting, the engine speed sensing system will resume normal function, the engine stalling phenomenon will disappear, and the digging force will return to normal.

The travel oil motor has just been repaired. The track moves faster at low throttle, but will not move at high throttle. What is the remedy?

This is because the valve plate was over-ground during maintenance and the grinding amount was too much, so the pressure between the valve plate and the cylinder plane is insufficient. At low throttle, the oil pressure is small, and it is not easy to leak between planes; at high throttle, the oil pressure increases, and overflow occurs between planes, causing the track to be unable to move at high throttle. The remedy is to add a gasket to the spring. If it is a butterfly spring, you can add an extra butterfly spring.

How do you diagnose a faulty fuel injector in an excavator engine?

To diagnose a faulty fuel injector, listen for any unusual engine noises or misfires. Perform a balance test to identify which injector is causing the problem. Use a diagnostic tool to check for fault codes related to the fuel system. If necessary, remove and inspect the injector for signs of clogging or damage, and replace it if needed.

About other questions pls contact me directily.

Excavator Spare Parts 4M50 Engine Assembly For Sany SY215

Excavator parts 708-2J-00030 Hydraulic Main Pump For Komatsu PC500LC-10R

Excavator Spare Parts YB60001906 Travel Gearbox For Hitachi EX1200-7 EX1200-6

Excavator parts 21P-60-K1502 Hydraulic Main Pump For Komatsu PC150LC-6K

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs