Complete Guide to Mini Excavator Parts and Accessories: Buy, Maintain, Upgrade

- Understanding for mini excavator parts and accessories

- What users are really looking for

- Why Quality Mini Excavator Parts and Accessories Matter

- Protect uptime and reduce operating costs

- Common Mini Excavator Parts and Accessories You Should Know

- Undercarriage parts: tracks, rollers, sprockets

- Hydraulic components: pumps, motors, valves

- Engine parts: assemblies, filters, and consumables

- Attachment accessories: buckets, breakers, augers

- Cabin and control parts: joysticks, seats, panels

- Electrical parts: alternators, starters, sensors

- Seal kits, cylinders, and wear parts

- How to Choose Between OEM and Aftermarket Mini Excavator Parts

- Pros and cons for purchasing decisions

- Ensuring Compatibility: Part Numbers, Serial Numbers, and Catalogs

- How to confirm the right mini excavator parts and accessories

- Sourcing Mini Excavator Parts and Accessories: Best Practices

- Where to buy and what to ask for

- Maintenance Schedule and Best Practices for Mini Excavator Parts

- Routine checks and preventive maintenance tips

- Installation and Safety Tips for Mini Excavator Parts

- Safe installation reduces warranty claims and accidents

- Cost-saving Strategies and Inventory Management

- How to lower parts spend without risking performance

- Upgrades and Accessory Choices to Boost Performance

- Accessories that improve productivity on the jobsite

- Kyotechs: One-Stop Supplier for Mini Excavator Parts and Accessories

- Company capabilities and why customers choose Kyotechs

- Conclusion: Buying and Maintaining Mini Excavator Parts and Accessories

- Practical next steps for buyers

- Frequently Asked Questions

Understanding for mini excavator parts and accessories

What users are really looking for

When someone searches for mini excavator parts and accessories, the intent is usually commercial and informational: they want to buy replacement parts or accessories, compare OEM vs aftermarket options, find installation and maintenance guidance, or confirm compatibility for a particular machine model. Searchers can be fleet managers, independent contractors, rental yards, or do-it-yourself owners who need parts for brands like Hitachi, Sany, Komatsu, Caterpillar, Volvo, Hyundai, Doosan, Kawasaki, Case, and Kobelco. Delivering clear product options, compatibility checks, and procurement paths satisfies that intent and helps convert leads into sales.

Why Quality Mini Excavator Parts and Accessories Matter

Protect uptime and reduce operating costs

High-quality parts and the right accessories directly affect machine uptime, jobsite efficiency, and total cost of ownership. Mini excavators, typically ranging from 1 to 10 metric tons (with many common models in the 1–6 ton class), are used in tight urban sites, landscaping, utility work, and light demolition. Worn or incorrect parts—undercarriage components, hydraulic seals, or improper attachments—can cause downtime, reduce fuel efficiency, and increase repair bills. Investing in correct mini excavator parts and accessories ensures safer operations and longer machine life.

Common Mini Excavator Parts and Accessories You Should Know

Undercarriage parts: tracks, rollers, sprockets

Undercarriage wear is one of the most frequent maintenance concerns for mini excavators. Rubber tracks, drive sprockets, track rollers, idlers, and track chains are critical parts. Choosing the right track type (rubber vs. steel) and maintaining proper tension will extend life and reduce replacement frequency.

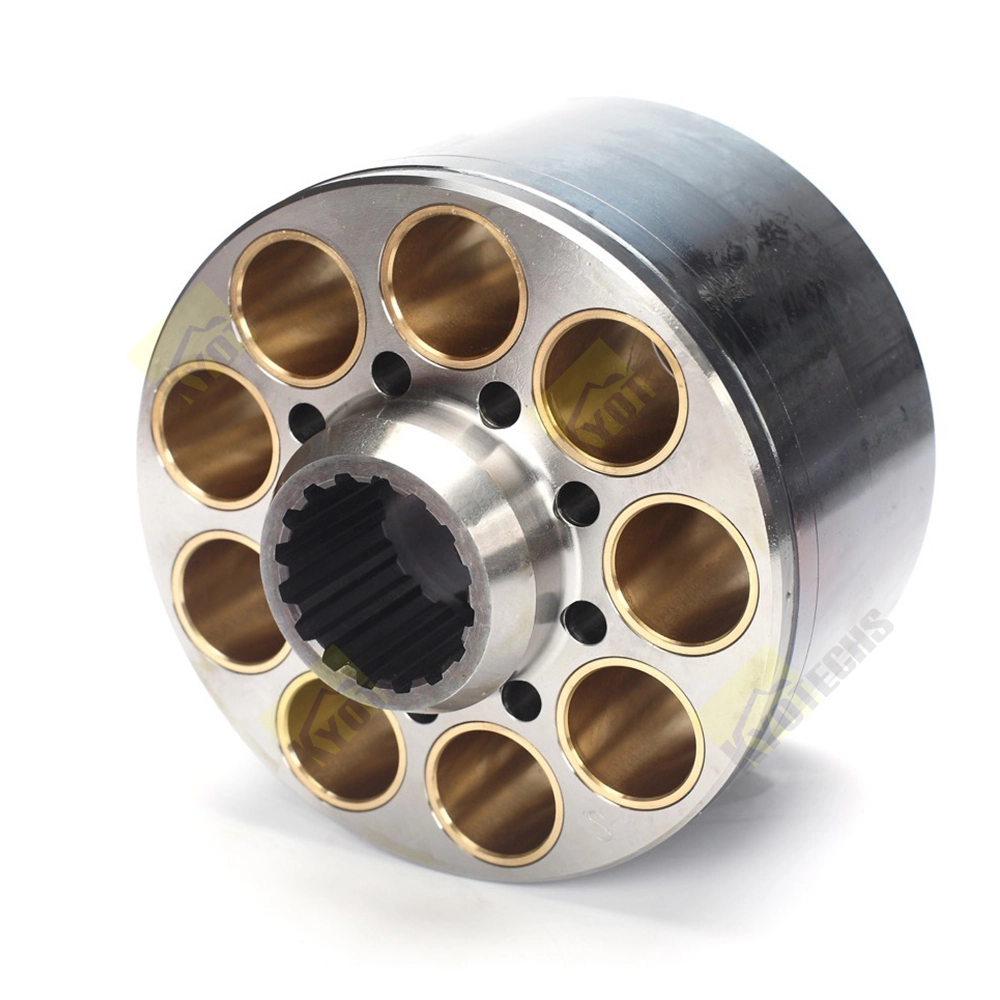

Hydraulic components: pumps, motors, valves

Hydraulics power everything on a mini excavator. Hydraulic pumps, motors, control valve assemblies, hoses, and seal kits are common replacement parts. Genuine or quality remanufactured hydraulic components reduce the risk of leaks and loss of performance. Regularly replacing filters and using proper hydraulic fluid can prevent premature failure.

Engine parts: assemblies, filters, and consumables

Engine assemblies and parts—including fuel injectors, turbochargers, air filters, oil filters, and gaskets—affect reliability and emissions. Proper engine maintenance extends service intervals and prevents catastrophic failures that are costly to repair.

Attachment accessories: buckets, breakers, augers

Attachments transform a mini excavator’s versatility. Typical accessories include buckets (trenching, grading), hydraulic breakers/hammers, augers, grapples, and quick couplers. Selecting compatible attachment kits and hydraulic flow requirements is essential to maintain performance and safety.

Cabin and control parts: joysticks, seats, panels

Driving cabin parts and interior components—control levers, joysticks, seats, instrument panels, and HVAC components—impact operator comfort and productivity. Replacing worn controls or upgrading to ergonomic seats can reduce operator fatigue and accidents.

Electrical parts: alternators, starters, sensors

Electrical failures are often the cause of unexpected downtime. Starters, alternators, wiring harnesses, sensors, and control modules must match the machine’s model year and configuration to ensure proper operation.

Seal kits, cylinders, and wear parts

Cylinder assemblies and seal kits are common wear items. High-quality seals and proper installation prevent hydraulic leaks and maintain cylinder performance. Keep spare seal kits on hand for planned maintenance.

How to Choose Between OEM and Aftermarket Mini Excavator Parts

Pros and cons for purchasing decisions

OEM (original equipment manufacturer) parts offer guaranteed fitment and warranty alignment with the machine manufacturer. Aftermarket parts can be more cost-effective and available for older or discontinued models. Key considerations: warranty, part longevity, availability, and compatibility. For critical systems like hydraulic pumps or engine components, OEM or reputable remanufactured parts are often the safer choice. For wear items such as filters or rubber mats, high-quality aftermarket options can reduce expenses without sacrificing performance.

Ensuring Compatibility: Part Numbers, Serial Numbers, and Catalogs

How to confirm the right mini excavator parts and accessories

Always verify the machine serial number (VSN/ESN) and the part number when ordering. Manufacturers often revise parts across model years—so visually similar components can differ internally. Use digital parts catalogs and exploded diagrams to match part numbers. If in doubt, consult an experienced parts supplier who can cross-reference numbers across brands—Kyotechs provides parts compatibility services and can match components for Hitachi, Sany, Komatsu, Caterpillar, Volvo, Hyundai, Doosan, Kawasaki, Case, and Kobelco machines.

Sourcing Mini Excavator Parts and Accessories: Best Practices

Where to buy and what to ask for

Buy from trusted suppliers with clear return policies, warranty coverage, and after-sales support. Whether you’re sourcing engine assemblies, hydraulic pumps, undercarriage components, or attachments, request part provenance (OEM, remanufactured, aftermarket), lead time, and technical support for installation. For fleet managers, vendor consolidation with one-stop suppliers reduces administrative overhead. Kyotechs, established in 2009, offers a full range of parts and one-stop solutions for excavator parts, engine repair, and hydraulic repair.

Maintenance Schedule and Best Practices for Mini Excavator Parts

Routine checks and preventive maintenance tips

Regular inspection keeps small issues from becoming major repairs. Key steps include daily visual inspections, weekly checks of fluid levels and track tension, and scheduled replacement of filters and fluids per the manufacturer’s intervals. Maintain a maintenance log, use genuine or high-quality replacement parts, and train operators to report abnormal noise, vibration, or leaks immediately. Proper lubrication of pivot points, correct torque on fasteners, and clean air intake systems extend parts life.

Installation and Safety Tips for Mini Excavator Parts

Safe installation reduces warranty claims and accidents

Always follow torque specifications, hydraulic bleeding procedures, and safety lockout/tagout practices during installation. For hydraulic components, use clean workspace practices to avoid contamination. When installing attachments, confirm hydraulic flow and pressure ratings, and verify secure mounting with correct pins and locks. If you’re not confident in the install, use professional service—Kyotechs offers one-stop repair solutions including engine and hydraulic services to ensure correct installation and safety compliance.

Cost-saving Strategies and Inventory Management

How to lower parts spend without risking performance

Implement preventive maintenance to reduce emergency repairs, bulk-order frequently replaced items, and consider remanufactured components for major assemblies. Maintain a small stock of high-turnover items—filters, seal kits, pins, and bolts—and use parts management software to forecast demand. Consolidating purchases with a supplier who offers multiple brands reduces logistical costs. Kyotechs’ One-Stop Excavator Software Solution can help manage parts inventory, streamline ordering, and optimize fleet maintenance schedules.

Upgrades and Accessory Choices to Boost Performance

Accessories that improve productivity on the jobsite

Popular upgrades include quick couplers for faster attachment changeover, hydraulic tilters for improved bucket angles, GPS/grade-control systems for precision work, and heavier-duty buckets for abrasive conditions. Choose accessories that match hydraulic flow and machine stability to avoid overloading mini excavators. Properly matched accessories can transform a mini excavator’s capability and deliver measurable productivity gains.

Kyotechs: One-Stop Supplier for Mini Excavator Parts and Accessories

Company capabilities and why customers choose Kyotechs

Kyotechs was established in 2009 and supplies a full range of excavator parts for brands including Hitachi, Sany, Kawasaki, Volvo, Hyundai, Doosan, Komatsu, Caterpillar, Case, and Kobelco. Our product range includes engine assemblies and parts, hydraulic pumps and parts, hydraulic motor assemblies and parts, control valve assemblies and parts, cylinder assemblies and seal kits, driving cabin assemblies and interior parts, electric parts, undercarriage parts, mini excavators, pile drivers, and hammers. We provide One-Stop Excavator Software Solution, One-Stop Engine Repair solution, and One-Stop Hydraulic Repair Solution—supporting procurement, compatibility checks, and professional repair services to minimize downtime and maintenance costs.

Conclusion: Buying and Maintaining Mini Excavator Parts and Accessories

Practical next steps for buyers

When searching for mini excavator parts and accessories, focus on compatibility, quality, and proven sourcing. Verify serial numbers, compare OEM versus aftermarket tradeoffs, prioritize preventive maintenance, and partner with a supplier that provides technical support and repair services. For reliable, wide-ranging support from parts to repair, Kyotechs delivers industry expertise and one-stop solutions that meet commercial needs for mini excavator parts and accessories. Contact a Kyotechs parts specialist to discuss specific models, lead times, and warranty options.

Frequently Asked Questions

What are the most common replacement parts for mini excavators?The most common replacements are undercarriage parts (tracks, rollers, sprockets), hydraulic seal kits and hoses, filters (air, fuel, oil, hydraulic), buckets and cutting edges, and electrical components like starters and alternators.

How can I check if a part is compatible with my mini excavator?Check the machine serial number and part number against manufacturer catalogs or consult an experienced parts supplier. Provide the model, year, and any attachment configuration to confirm fitment.

Is it better to buy OEM parts or aftermarket parts?Use OEM for critical systems (engines, hydraulics) if warranty and guaranteed fit matter. High-quality aftermarket parts can be cost-effective for wear items. Evaluate warranty, longevity, and supplier reputation when deciding.

Can I install hydraulic pumps or cylinders myself?Minor hydraulic work like hose replacement can be done by experienced technicians, but pump swaps and cylinder rebuilds require proper tools, cleanliness, and hydraulic system knowledge. Consider professional service for complex repairs to avoid contamination and safety risks.

What accessories increase a mini excavator’s productivity?Quick couplers, hydraulic breakers, augers, tilt buckets, and GPS/grade-control systems are common productivity-boosting accessories. Ensure hydraulic flow and machine stability are compatible with the accessory specifications.

How does Kyotechs support fleet maintenance?Kyotechs provides parts for a wide range of brands, One-Stop Excavator Software Solution for inventory and maintenance management, and One-Stop Engine and Hydraulic Repair Solutions to reduce downtime and streamline service. Contact Kyotechs to get a tailored plan for your fleet.

Kyotechs best professional Rexroth excavator parts Manufacturers and supplier brand

The Ultimate Guide to 1339 Excavator Travel Motor by Kyotechs

Kyotechs best professional komatsu excavator parts Manufacturers and supplier brand

Enhancing Your Excavator Performance with Quality Hydraulic Parts

FAQS

How to change the hydraulic oil in a track excavator?

First, park the excavator on a flat, safe surface, shut off the engine, and release the system pressure. Then, open the drain plug on the hydraulic tank to drain the old oil. Replace the filters, refill with new hydraulic oil, start the engine, run the system to expel air, and check the oil level.

How to test the system after the hydraulic pump is replaced?

The way to test the system after replacement is to start the excavator, slowly operate all hydraulic functions, check system pressure, leakage and operation, and ensure that everything is normal.

How to avoid the derailment (chaining) of the crawler chain of the excavator?

1. When walking on the construction site, please try to place the travel motor behind the walking to reduce the squeezing of the sprocket.

2. The continuous walking time of the machine cannot exceed 2 hours. The walking time on the construction site should be minimized. If necessary, it is recommended to walk after a short stop in the middle.

3. Avoid raised hard objects when walking to avoid stress concentration on the track chain.

4. Confirm the tightness of the crawler, adjust the crawler tighter in soft places such as soil, and adjust the crawler looser when walking on stones. It is not good to have a crawler that is too loose or too tight. Too loose will cause the crawler to derail easily, and too tight will cause the chain sleeve to wear too quickly.

5. Check whether there are foreign objects such as stones in the crawler frequently, and clean them if there are.

6. When working on a muddy construction site, it is necessary to frequently idle to discharge the soil deposited in the crawler.

7. Try to avoid the excavator turning in circles on the spot.

8. Regularly check the rail guard and the rail guard welded under the guide wheel.

How to check for leaks in the hydraulic system?

Check whether there are oil stains on the hydraulic oil tank, oil pipe and joints, and repair them in time if leaks are found.

How to handle hydraulic pump pressure fluctuations?

Possible air in the system, clogged filter, or worn pressure relief valve.

Solution: Bleed air from the system, clean or replace filter, replace pressure relief valve.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs