PC200-7 PC Valve: Precision and Performance Unleashed

Introducing the PC200-7 PC Valve: Unmatched Precision for Superior Performance

Upgrade your machinery with the precision-engineered PC200-7 PC Valve, a vital component for optimizing hydraulic efficiency and performance. Designed for compatibility with a wide range of industrial equipment, this valve is your go-to solution for enhancing operational productivity and reliability.

Key Features:

1. Exceptional Durability: Manufactured from high-grade materials that withstand extreme temperatures and pressures, the PC200-7 PC Valve guarantees long-term durability and robust performance.

2. Precision Engineering: Engineered with meticulous attention to detail, this PC valve ensures seamless operation, reducing the likelihood of system failures and increasing the lifespan of your equipment.

3. Improved Efficiency: The innovative design of the PC200-7 PC Valve enhances hydraulic system efficiency, allowing for smoother and quicker operations. This means less downtime and more productive work hours, an essential advantage in any high-demand setting.

4. Easy Installation: With its user-friendly design, the PC200-7 PC Valve allows for quick and hassle-free installation. Save time and reduce maintenance costs with a component that integrates effortlessly into your existing setup.

5. Versatile Compatibility: Specifically designed to fit a variety of heavy-duty machines, the PC200-7 PC Valve offers versatile compatibility, making it a preferred choice for industries utilizing diverse equipment.

Why Choose the PC200-7 PC Valve?

Leveraging advanced engineering and years of industry expertise, the PC200-7 PC Valve stands out as a superior choice for businesses seeking reliability and top-tier performance. It addresses the needs of modern machinery with precision and resilience, ensuring your operations run smoothly and efficiently.

Whether you're managing a construction site, an industrial facility, or any other mechanical-heavy operation, the PC200-7 PC Valve is designed to meet your aspirations for excellence. Delivering optimal control and responsiveness, this valve is poised to take your hydraulic systems to the next level.

Invest in the PC200-7 PC Valve and experience the difference in performance and longevity. It's more than just a component—it's a critical element in the success of your operations. Elevate your equipment, enhance your productivity, and enjoy the peace of mind that comes with superior product quality.

Our Advantages

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

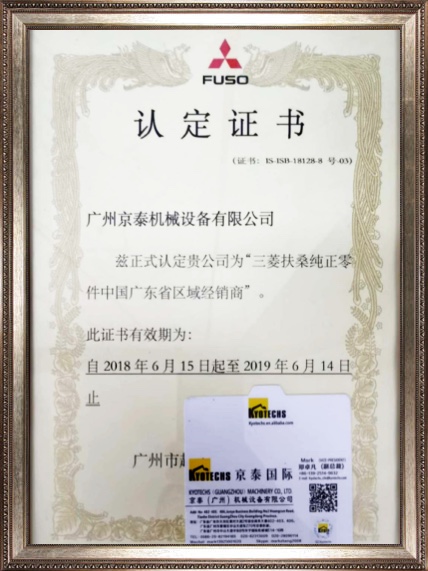

Certificate display

HANDOK Hydraulic

MITSUBISHI FUSO

TUV

Question you may concern

How do you diagnose a faulty fuel injector in an excavator engine?

To diagnose a faulty fuel injector, listen for any unusual engine noises or misfires. Perform a balance test to identify which injector is causing the problem. Use a diagnostic tool to check for fault codes related to the fuel system. If necessary, remove and inspect the injector for signs of clogging or damage, and replace it if needed.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

Why does the hydraulic pump overheat under low load?

Possible restricted fluid flow, cooling system failure, or high oil viscosity.

Solution: Check and clear restricted areas, check and repair cooling system, use correct viscosity oil.

How to check the hydraulic oil level?

Park the excavator on a flat ground, turn off the engine and wait for a while, then check the hydraulic oil level through the oil level gauge of the hydraulic oil tank.

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs