How does a hydraulic pump work in an excavator?

How does a hydraulic pump work in an excavator? Kyotechs explains the key mechanics, from fluid pressure to efficient power conversion, boosting excavator performance. Learn more on our site.

- Understand what a hydraulic pump is?

- How does a hydraulic pump work?

- What are the most common types of hydraulic pumps?

- 1.Gear pumps

- 2.Vane pumps

- 3.Piston pumps

- What are some common problems with hydraulic pumps?

- 1.Low pressure or loss of pressure

- 2.Excessive noise

- 3.Overheating

- 4.Oil leakage

- Conclusion

Excavators are powerful machines widely used in construction, mining, and other industries, and their efficient operation relies heavily on various components working together. Among these components, the hydraulic pump plays a crucial role. If you've ever wondered about the inner workings of an excavator's hydraulic system, understanding how the hydraulic pump functions is a great starting point.

Understand what a hydraulic pump is?

Hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. In the context of an excavator, it serves as the heart of the hydraulic system. Its main purpose is to generate flow and pressure of hydraulic fluid, which is then used to power the various hydraulic actuators, such as the boom, arm, and bucket cylinders, as well as the tracks for movement.

Hydraulic pumps are designed to take in hydraulic fluid (usually oil) from a reservoir and push it through the hydraulic lines at a certain pressure. This pressurized fluid acts as a medium to transmit force, allowing the excavator to perform heavy-duty tasks with precision and power.

How does a hydraulic pump work?

The working principle of a hydraulic pump in an excavator is based on the concept of fluid dynamics and Pascal's law, which states that pressure applied to an enclosed fluid is transmitted undiminished to all portions of the fluid and the walls of its container.

Here's a step-by-step breakdown of how it operates:

First, the hydraulic pump is connected to the excavator's engine. When the engine starts running, it drives the pump's input shaft, causing internal components of the pump to rotate or move. As the pump operates, it creates a low-pressure area at its inlet port. This low pressure draws hydraulic fluid from the reservoir through a suction line, which is typically equipped with a filter to prevent contaminants from entering the system.

Once the fluid enters the pump, the rotating or moving components (such as gears, pistons, or vanes) trap the fluid and displace it towards the outlet port. During this displacement process, the volume of the space where the fluid is held decreases, which increases the pressure of the hydraulic fluid. The pressurized fluid is then forced out of the pump's outlet port into the hydraulic lines.

This high-pressure hydraulic fluid is directed to the various hydraulic cylinders and motors in the excavator. When the fluid reaches a cylinder, the pressure pushes against the piston inside the cylinder, causing it to move. This linear movement of the piston is what enables the boom to lift, the arm to extend or retract, and the bucket to dig or dump. For the tracks, the hydraulic fluid powers hydraulic motors, which convert the hydraulic energy back into mechanical rotational energy to drive the tracks.

After the fluid has done its work in the actuators, it flows back to the reservoir through return lines, completing the hydraulic circuit. The process repeats continuously as long as the pump is operating, providing a steady supply of pressurized fluid to keep the excavator's functions running smoothly.

What are the most common types of hydraulic pumps?

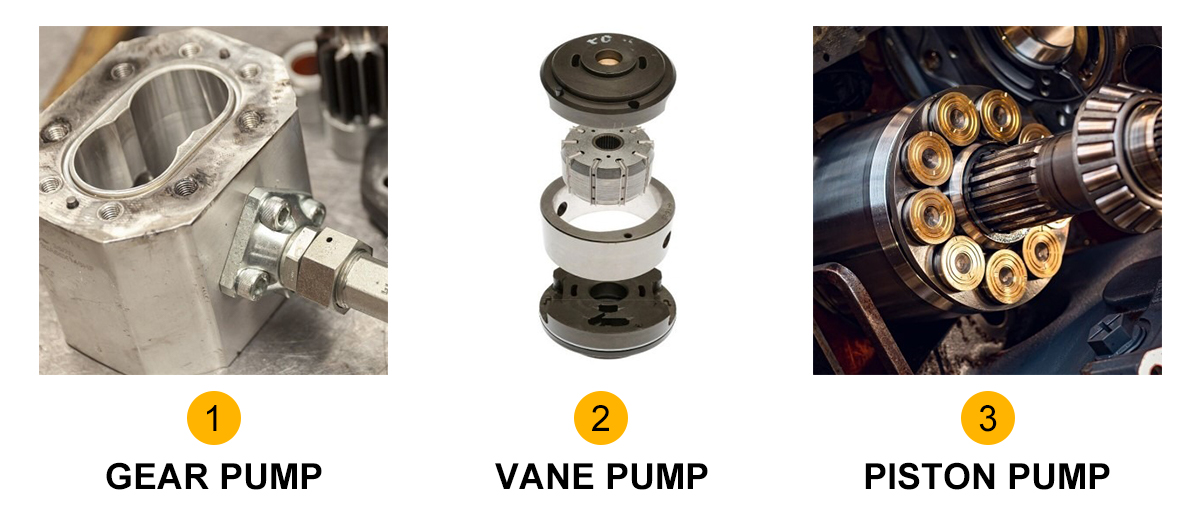

There are several types of hydraulic pumps used in excavators, each with its own unique design and characteristics.

The most common ones include:

1.Gear pumps

These are one of the simplest and most widely used types of hydraulic pumps. They consist of two meshing gears inside a housing. As the gears rotate, fluid is trapped between the teeth of the gears and the housing, and is carried from the inlet to the outlet. They are often used in smaller excavators or for less demanding hydraulic functions.

2.Vane pumps

Vane pumps use a rotor with several sliding vanes that fit into slots in the rotor. The rotor is offset within a circular housing. As the rotor rotates, the vanes are pushed outwards by centrifugal force, creating chambers between the vanes, rotor, and housing. Fluid is drawn into the chambers as they expand at the inlet, and is pushed out as the chambers contract at the outlet. Vane pumps offer better efficiency than gear pumps and can handle higher pressures. They are commonly used in medium-sized excavators.

3.Piston pumps

Piston pumps are more complex but provide higher pressure and efficiency, making them suitable for large excavators and heavy-duty applications. There are two main types of piston pumps: axial piston pumps and radial piston pumps. In axial piston pumps, a series of pistons are arranged parallel to the pump's shaft. The pistons reciprocate within cylinders as the swashplate or cylinder block tilts, drawing in and pushing out fluid. Radial piston pumps have pistons arranged radially around a central cam. As the cam rotates, it pushes the pistons in and out, creating the pumping action.

What are some common problems with hydraulic pumps?

Like any mechanical component, hydraulic pumps in excavators can experience problems over time due to wear, contamination, or improper maintenance.

Some common issues include:

1.Low pressure or loss of pressure

This can be caused by worn pump components, such as gears, vanes, or pistons, which allow fluid to leak back instead of being properly pressurized. Contamination in the hydraulic fluid can also damage the pump's internal parts, leading to pressure loss. A clogged filter or a leak in the hydraulic lines can also result in low pressure.

2.Excessive noise

Unusual noises from the hydraulic pump, such as whining, grinding, or knocking, can indicate problems. This may be due to cavitation, which occurs when the pump doesn't receive enough fluid, causing air bubbles to form and collapse, leading to noise and damage. Worn or damaged components, such as bearings or gears, can also produce noise.

3.Overheating

Overheating of the hydraulic pump can be caused by a variety of factors, including low fluid levels, dirty fluid, or a malfunctioning cooling system. When the pump overheats, it can reduce the viscosity of the hydraulic fluid, leading to increased leakage and reduced efficiency. Prolonged overheating can cause severe damage to the pump and other components in the hydraulic system.

4.Oil leakage

Leaks can occur at the pump's seals, gaskets, or connections. This can be due to worn or damaged seals, loose fittings, or excessive pressure. Oil leakage not only reduces the amount of fluid in the system but can also lead to environmental contamination and damage to other components.

Conclusion

The hydraulic pump is an essential component of an excavator's hydraulic system, responsible for converting mechanical power into hydraulic energy to drive the machine's various functions. Understanding how it works, the different types available, and the common problems that can arise is crucial for proper maintenance and operation of excavators.

By ensuring that the hydraulic pump is in good working condition, through regular maintenance, proper fluid levels, and keeping the system clean, you can maximize the performance, efficiency, and lifespan of the excavator.

What are the solutions for excavator steering failures?

What causes plunger pump failures? What do plunger pumps work?

What is the reason why the excavator hydraulic pump makes abnormal noise?

How Does an Excavator Hydraulic Pump Work? What Are the Different Types of Hydraulic Pumps?

FAQS

What parts you have?

We are specialized in excavator spare parts, such as travel motor gearbox assy & parts, swing gearbox motor assy & parts, and hydraulic pump motor assy and spare parts. If any are needed, we can also supply them as per your requirements.

Do you only sell or repair?

Yes, we sell parts and have a repair team to offer support.

1. Software solution.

A. ECU & Monitor Reprogram

B. DPF Program Solution

C. Software refit

2. Engine Rebuild & Testing

Maintenance Team Support

A. ET for Caterpillar Diagnosis

B. Inline 6 for Cummins/Komatsu/Hyundai Diagnosis

C. IDSS for Hitachi/Isuzu/Case/Sany/Sumitomo/JCB/XCMG/Isuzu Truck Diagnosis

D. DX2/NEXIQ for Kobelco/Hino truck Diagnosis

E. Vocom for Volvo/Volvo truck/Penta Diagnosis

F. DST-i for KUBOTA DENSO Diagnosis

3. hydraulic Remanufacture & Testing

A. Offer new or rebuilt hydraulic pump & motor

B. Control valve & main pump repair & rebuild knowledge

C. Offer stable and cheap hydraulic test machines

D. All rebuild valves, pumps, and motors offer testing video for cilent

If i don'thave part number, can you check for me?

Yes, excavator model, old photos, and size are also available to confirm the correct parts you need.

Which shipping term you can supply?

By sea, air or by express ( DHL, Fedex, TNT, UPS, EMS)

How long does it take to my address?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs