How to delete the DPF program from the controller?

Learn how to delete the DPF program from the controller with Kyotechs' expert guide. This video tutorial is tailored for E336E and E312E Controllers, ensuring a smooth process. Follow our step-by-step instructions to enhance your equipment's performance efficiently.

In the excavator industry, diesel particulate filters (DPF) are widely used in excavator engine control systems. The DPF program can effectively capture and store particulate pollutants in the engine exhaust, significantly reduce exhaust emissions, and help excavators meet environmental regulations.

What is the specific operation process?

Preliminary preparation:

1. Programming equipment: Select a pass-through programming device that meets the SAE J2534 standard and ensure that the accompanying software CD contains the API DLL file that matches the brand and model of the target excavator.

2. Software adaptation: Get professional software for deleting the DPF program, and ensure that the software source is reliable and the version is compatible.

3. Safety protection: Wear insulating gloves and choose a safe operation site away from flammable and explosive items.

4. Equipment connection: Turn off the main power switch of the excavator, connect the programming device to the computer through the USB interface, and then find the excavator diagnostic interface (commonly found under the driver's seat or on the side of the engine compartment), and correctly connect the other end of the programming device to it. Then turn on the excavator power to the ON gear, but do not start the engine.

5. Software startup and detection: Start the software for deleting the DPF program on the computer, and the software will automatically detect the programming device and excavator information. If there is a connection abnormality or information mismatch, you need to check the connection line and software version until the test passes.

6. Read the original program: Select the "Read ECU Program" option in the software interface. The software establishes communication with the excavator ECM through the programming device and reads all program data including the DPF control program. This process may take 3-5 minutes, and the device connection must be kept stable during this period.

7. Program modification: According to the software operation guide, accurately locate the relevant part of the DPF program in the read program code, and modify or directly delete its relevant parameters. This step requires high caution to avoid affecting the normal operation logic of the engine.

8. Write a new program: After completing the modification, select the "Write ECU Program" option to write the modified program data to the excavator ECM. During the writing process, be sure to ensure that the power supply is stable and the device is firmly connected. Interference with the operation is strictly prohibited. After the writing is successful, the software will give a prompt.

9. Equipment removal: Turn off the power of the excavator, disconnect the programming device from the diagnostic interface first, then unplug the USB interface from the computer, and properly organize the equipment and software.

Among these, what kind of failure will occur if the DPF performance is poor?

1. Engine power reduction: When the DPF is blocked due to the accumulation of particulate matter, the exhaust back pressure increases significantly. In order to overcome this resistance, the engine needs to consume more energy, resulting in a significant reduction in output power. For example, during excavation operations, the excavation force is significantly weakened, and the work efficiency drops significantly.

2. Increased fuel consumption: Poor exhaust makes the engine burn incompletely. In order to maintain working operation, the fuel injection volume has to be increased. In the long run, fuel consumption will rise sharply and operating costs will increase significantly.

3. Automatic protection shutdown: When the blockage is serious, the excavator control system detects an abnormality and triggers the automatic protection mechanism to shut down the engine to avoid further damage. This not only interrupts the operation but may also cause equipment damage or safety accidents.

Solutions to poor DPF performance

1. Active regeneration: When the excavator is running, if the DPF reaches a certain degree of blockage, the control system will automatically start the active regeneration process. By increasing the exhaust temperature, the particulate matter is burned. At this time, the driver needs to keep the engine running at high idle speed for a period of time to ensure that the regeneration is completed.

2. Passive regeneration: When the engine is working normally, the oxygen and particulate matter in the exhaust gas undergo oxidation reaction at a lower temperature under the action of the catalyst inside the DPF to achieve regeneration. However, this method has high requirements for engine operating conditions and cannot be effectively carried out under all operating conditions.

3. Manual cleaning: Remove the DPF from the engine exhaust system and clean it with special cleaning agents and equipment. However, this operation is more complicated and requires professional maintenance personnel to operate, and frequent disassembly may affect the service life of the DPF.

Kyotechs can install a DPF program from the engine, and can also provide a new engine, fuel pump and injector for this model

If you encounter any problems or questions, please feel free to contact us

How to prove that the ECU works properly in the DPF engine?

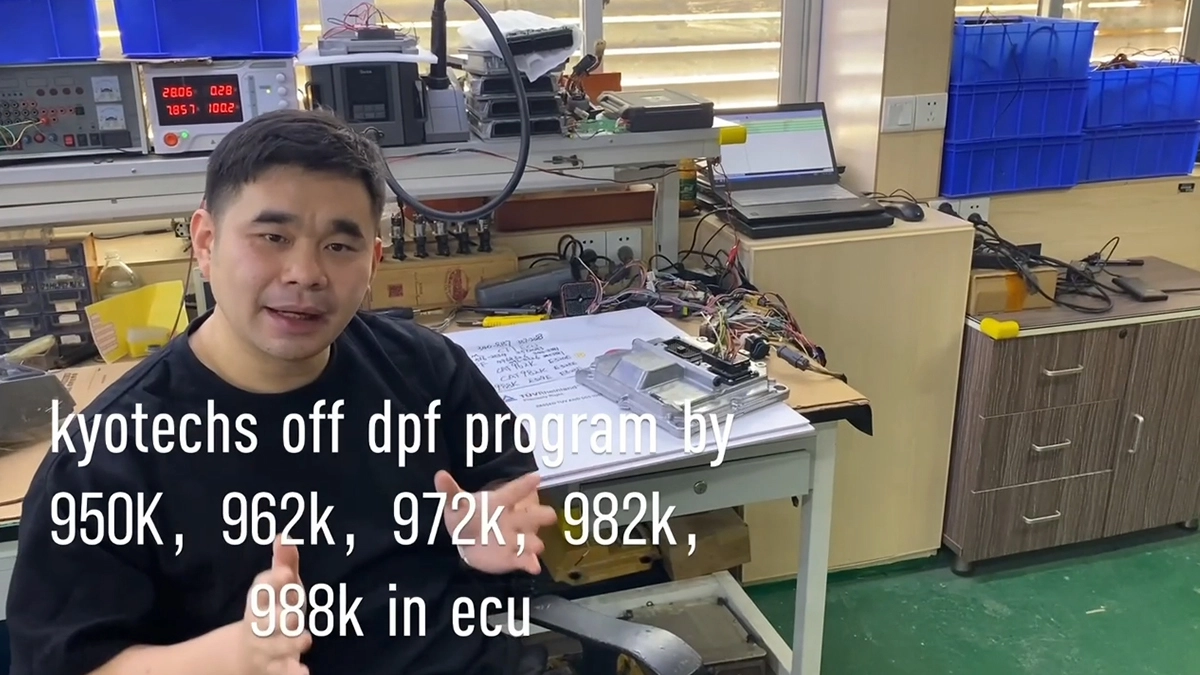

How to turn off the DPF program in the ECU?

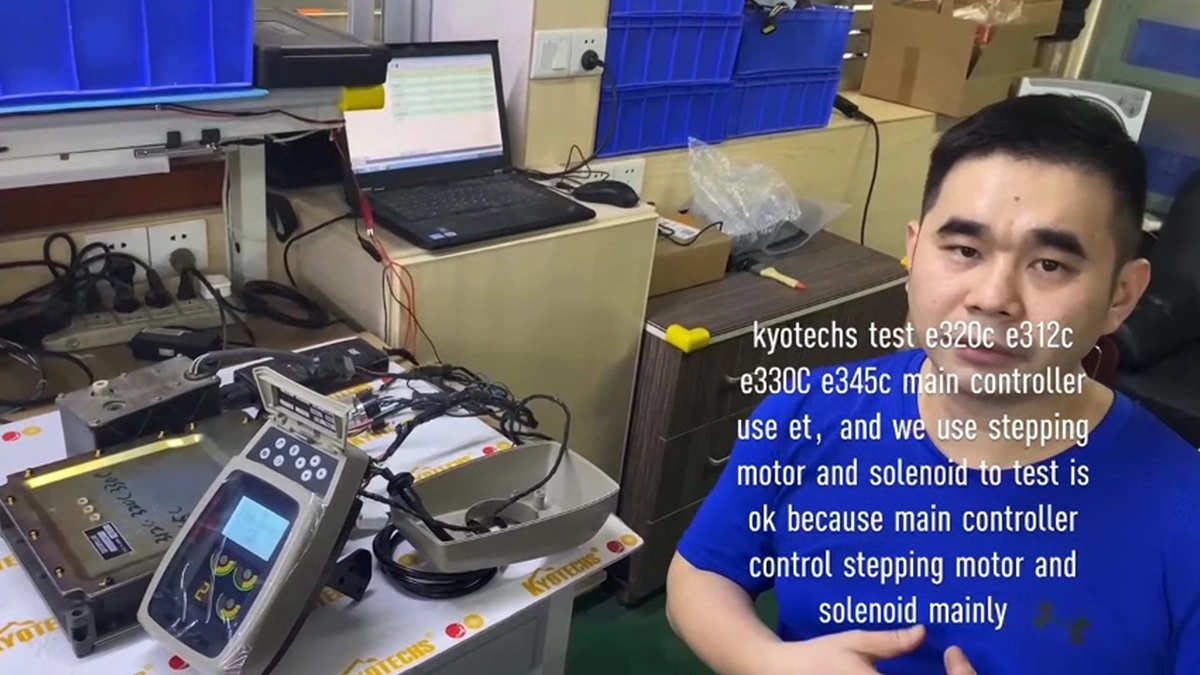

Can the main controller ET be tested with stepper motors and solenoid valves?

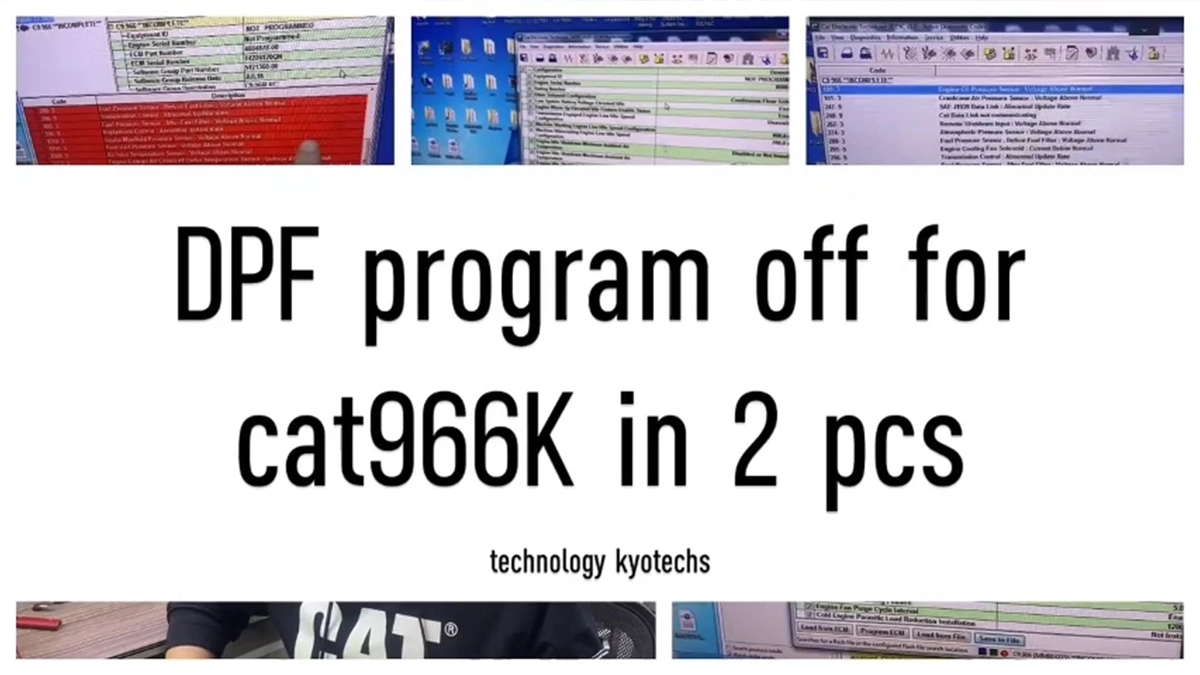

How to check if DPF program is turned off?

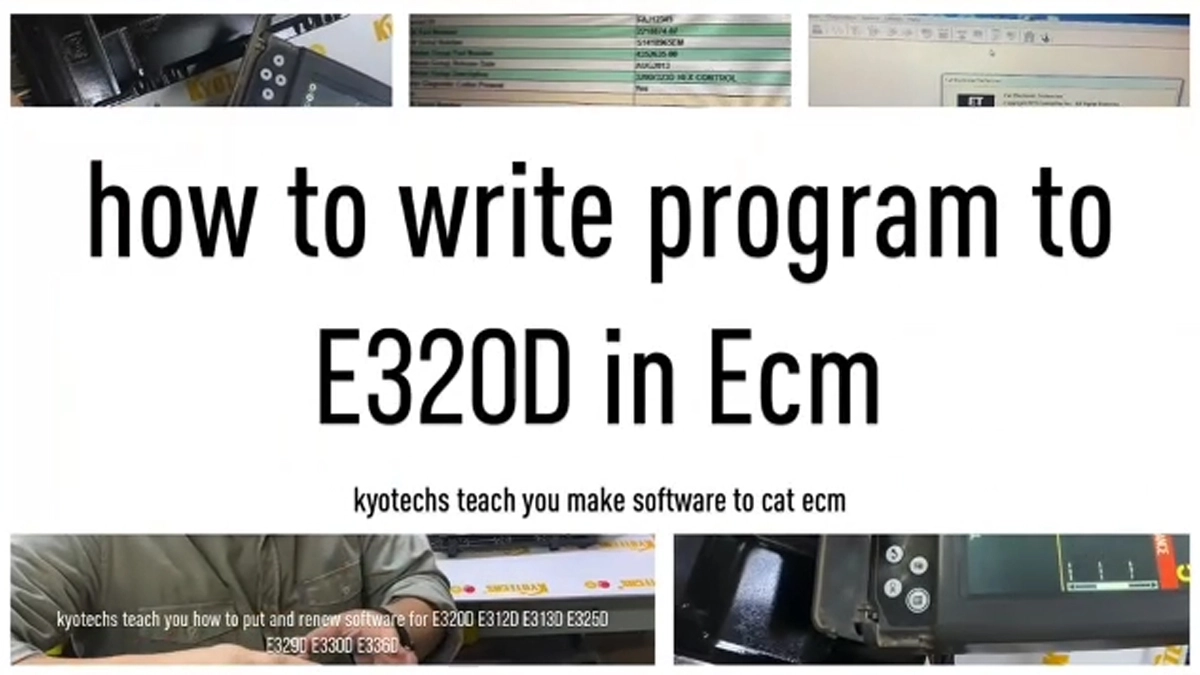

How to write program to E320D in ECM?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs