How to write program to E320D in ECM?

Learn how to write a program to E320D in ECM with Kyotechs. This video guides you through the process, ensuring your E320D ECM is programmed correctly. Discover efficient techniques and best practices for optimal performance. Trust Kyotechs for all your ECM programming needs.

In the daily use and maintenance of the excavator, writing the program to the electronic control module (ECM) of the E320D is an important operation. This helps to improve the performance of the equipment, repair faults and adapt to different work requirements. The following is a detailed introduction to the steps of writing the program.

1. Preparation before operation

Before writing the program, you must be fully prepared. You need to prepare an adaptive diagnostic tool, such as a Caterpillar-specific diagnostic instrument, which can establish a stable connection with the ECM. At the same time, make sure that the laptop has the corresponding diagnostic software installed and the software version is compatible with the ECM. You must also prepare the target program file, which must be obtained from a formal channel to ensure the integrity and accuracy of the file. In addition, check the power supply of the excavator to ensure stable power supply during the writing process to avoid writing failure or damage to the ECM due to power outages.

2. What devices need to be connected?

First, correctly connect the diagnostic instrument to the laptop, usually using a USB interface. Open the diagnostic software and wait for the software to recognize the diagnostic instrument.

Next, find the ECM diagnostic interface on the excavator, which is usually located near the cab or engine compartment. Connect the diagnostic instrument's cable to the interface firmly, ensuring that the connection is tight to avoid looseness that affects communication. After completing the connection, turn on the excavator's power switch, but do not start the engine, let the diagnostic instrument communicate and handshake with the ECM, and confirm that the connection is successful in the software.

3. Back up the original program

To prevent the failure of writing the new program or compatibility issues, it is very important to back up the original program. Find the backup function option in the diagnostic software and follow the prompts. During the backup process, the software will read the original program in the ECM and save it to the specified location on the computer. This process requires patience. Do not perform other operations during this period to ensure that the backup data is complete.

4. Write a new program

Select the program write function in the software and find the target program file prepared previously. Carefully check the file information to ensure that the file version matches the ECM. After confirmation, set the relevant write parameters, such as device model, serial number, etc. After the settings are completed, click the Start Write button. During the writing process, pay close attention to the software prompts and progress bar. If an error message appears, stop the operation immediately, check the problem and solve it before trying again.

5. Test and verify

After the program is written, the excavator should be fully tested. Start the engine and check whether it starts smoothly, runs stably, and whether the speed can be adjusted normally. At the same time, operate the various working devices of the excavator, such as the boom, dipper, bucket, etc., to observe whether their movements are sensitive and coordinated. Also check whether the pressure and flow of the hydraulic system are normal. If any abnormality is found, analyze the cause and solve it in time.

Writing the program to the ECM of the excavator E320D requires rigorous operation and sufficient preparation. Follow the above steps and the content in the video to ensure the safety and success of the program writing and keep the excavator in good working condition at all times.

If you have any questions or doubts, please come in for consultation

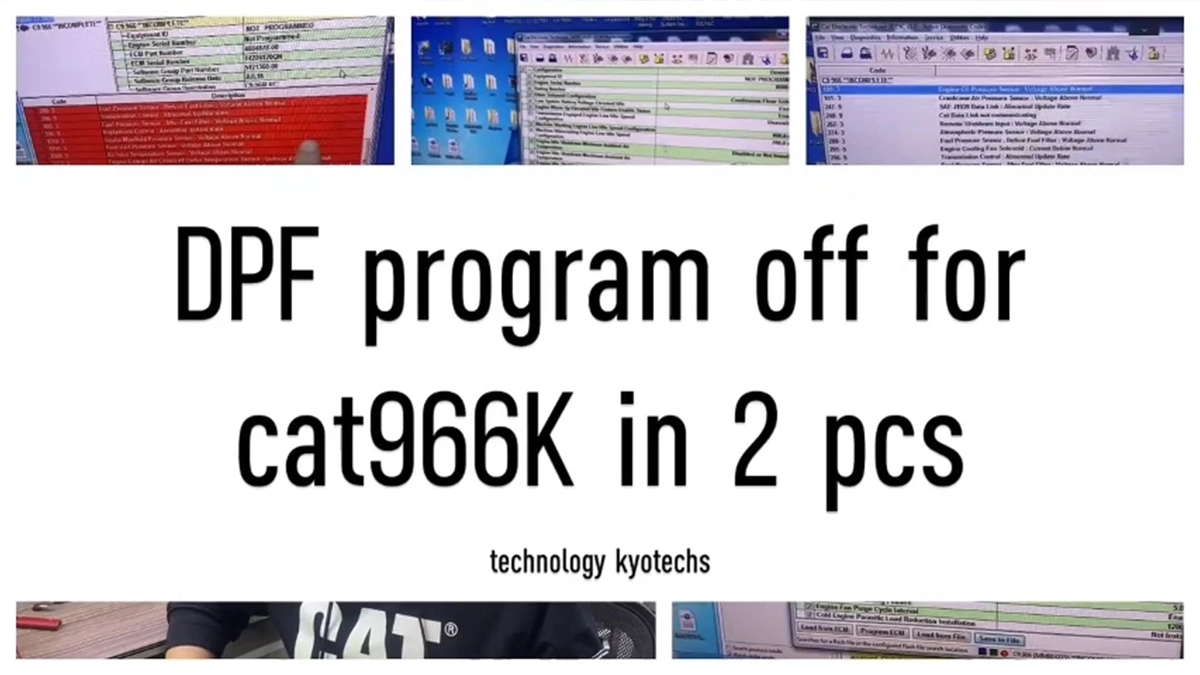

How to prove that the ECU works properly in the DPF engine?

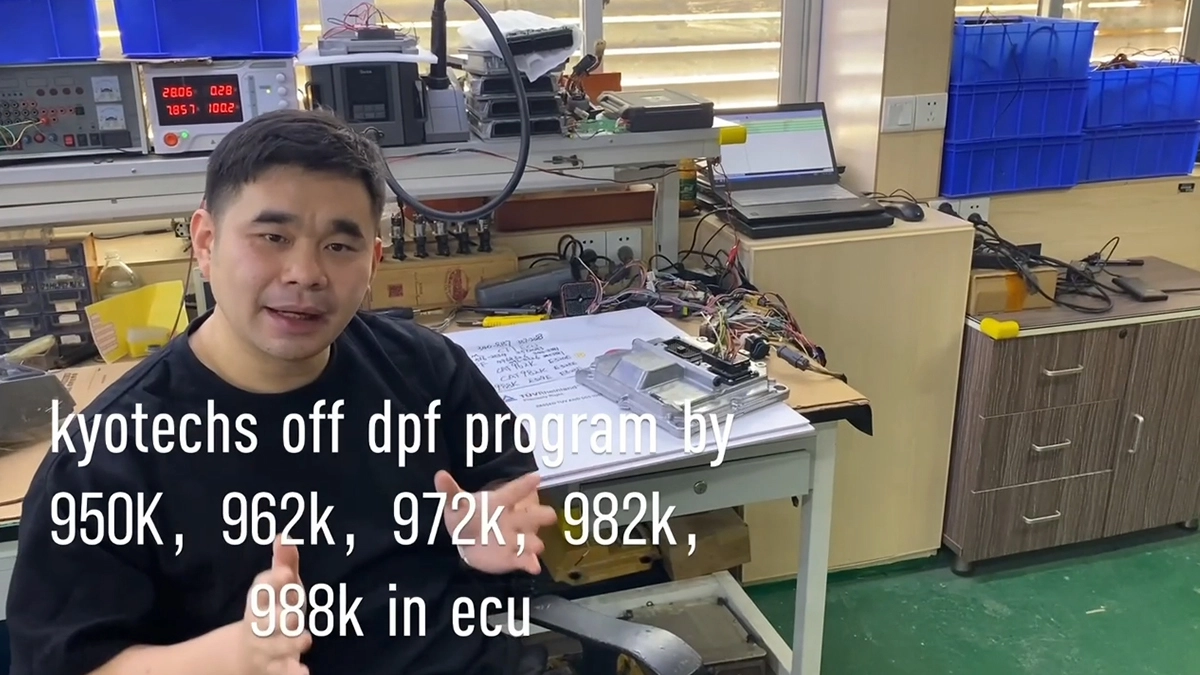

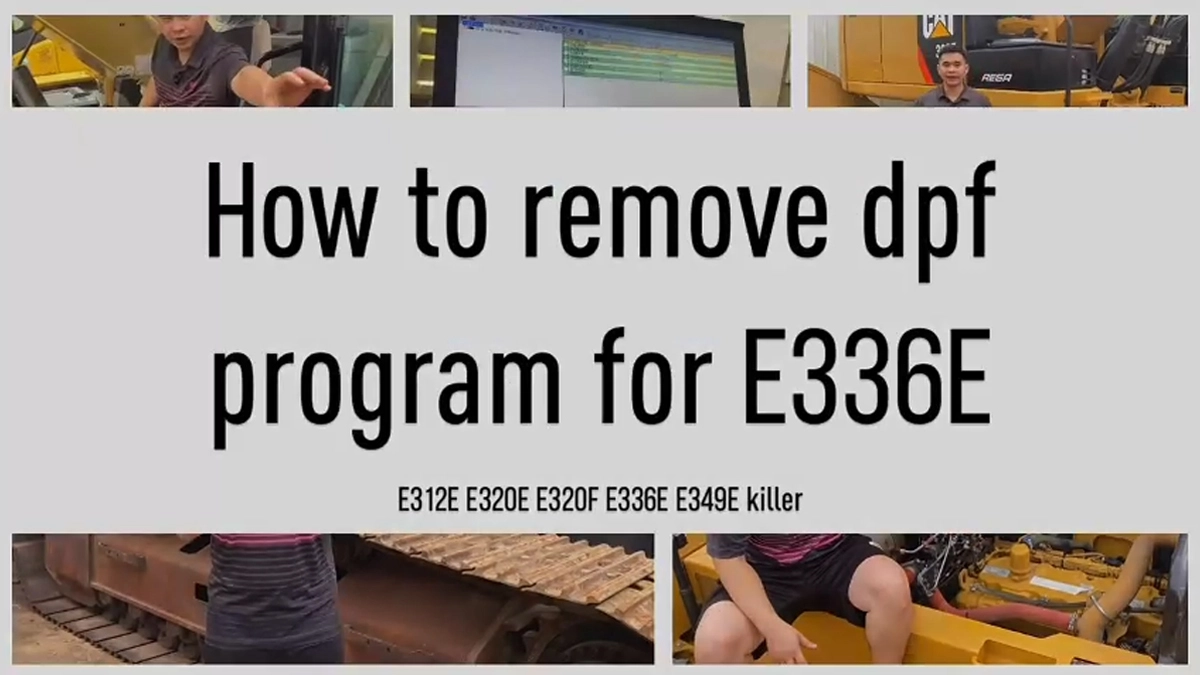

How to turn off the DPF program in the ECU?

How to delete the DPF program from the controller?

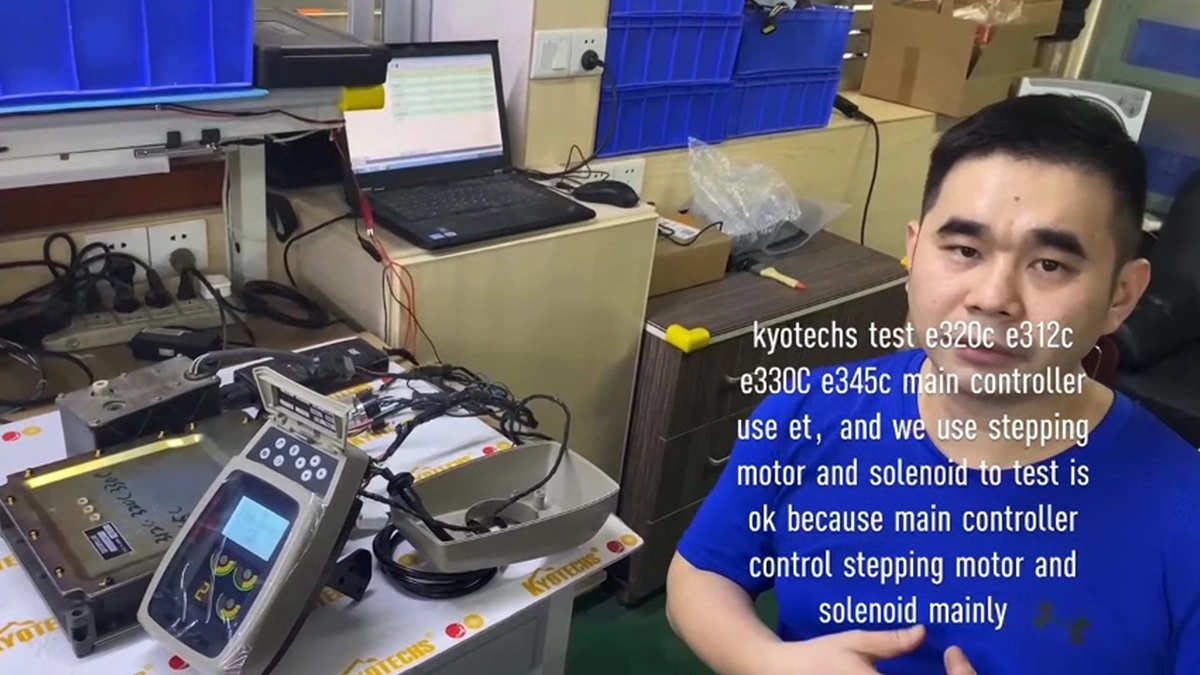

Can the main controller ET be tested with stepper motors and solenoid valves?

How to check if DPF program is turned off?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs