How to prove that the ECU works properly in the DPF engine?

Learn how to verify the proper functioning of the ECU in your DPF engine with Kyotechs' E320E Controller. Our video guide, How to prove that the ECU works properly in the DPF engine?, offers step-by-step instructions for reliable performance assessment.

In the excavator industry, in order to meet increasingly stringent environmental protection requirements, DPF (diesel particulate filter) engines have been widely used. As the core component of the engine control system, the working status of the E320E computer board directly affects the performance and reliability of the DPF engine. So, how can we prove that the E320E computer board works properly in the DPF engine?

1. Fault diagnosis system detection

The E320E computer board has an advanced fault diagnosis system built in. By connecting the diagnostic interface of the excavator with professional diagnostic equipment, the fault codes stored in the computer board can be read. If there is no fault code related to the E320E computer board, this is an important sign of its normal operation. For example, when the engine has problems such as difficulty starting and unstable idling, if the fault diagnosis instrument shows that the E320E computer board is fault-free, the fault factor of the computer board itself can be preliminarily ruled out. However, it should be noted that some intermittent faults may not be recorded immediately, so it is necessary to combine other detection methods for comprehensive judgment.

2. Sensor signal monitoring

The DPF engine is equipped with many sensors, such as air flow sensor, water temperature sensor, oxygen sensor, DPF differential pressure sensor, etc. These sensors are responsible for transmitting the real-time operating parameters of the engine to the E320E computer board. Professional detection tools can be used to monitor the accuracy of the sensor output signal. Under different engine operating conditions, such as idling, no-load, and load operation, the output signal of each sensor should be within the specified reasonable range. Taking the air flow sensor as an example, when the engine is running at high speed, its output signal should accurately reflect the increase in intake volume. If the sensor signal is abnormal, the E320E computer board may make incorrect control instructions, resulting in reduced engine performance. If all sensor signals can be transmitted normally and meet the standards, it means that the E320E computer board has the ability to accurately receive external information.

3. Actuator action observation

Based on the signals from the sensors, the E320E computer board will issue control instructions to various actuators after analysis and processing, such as injectors, throttle actuators, EGR valves (exhaust gas recirculation valves), DPF regeneration control valves, etc. During the operation of the engine, the actual action of the actuator can be observed to determine whether the control function of the E320E computer board is normal. At the moment of engine start-up, the injector should be able to accurately inject fuel according to the instructions of the computer board, and the timing and amount of fuel injection should match the requirements of engine start-up. When the DPF needs to be regenerated, the regeneration control valve should be able to open or close in time to ensure that the carbon smoke in the DPF can be effectively removed. If the actuator can accurately execute the instructions of the E320E computer board, it means that the output control function of the computer board is normal.

4. Data flow analysis

Reading the data flow of the E320E computer board with the help of professional diagnostic equipment is an important means to determine its working status. The data flow contains various real-time operating parameters of the engine, such as engine speed, load, injection amount, intake volume, DPF temperature and pressure difference. By analyzing the logical relationship between these parameters, we can have a deep understanding of the working condition of the engine and whether the control strategy of the E320E computer board is correct. When the excavator is digging and the engine load gradually increases, the fuel injection volume should be increased accordingly, and the intake volume should also be reasonably adjusted to maintain a suitable air-fuel ratio. If the parameter changes in the data stream are consistent with the working principle and design logic of the engine, then it can be proved from the side that the E320E computer board is normal in coordinating the work of various engine systems.

5. Hardware status check

The visual inspection of the hardware of the E320E computer board should not be ignored. Check whether there are obvious damage, deformation, and burn marks on the appearance of the computer board, and whether the connection plugs are firm, loose, or corroded. If the appearance of the computer board hardware is intact and the connection line is normal, then the possibility of abnormal operation due to physical damage to the hardware or poor connection will be greatly reduced.

By comprehensively using the above-mentioned fault diagnosis system detection, sensor signal monitoring, actuator action observation, data flow analysis, and hardware status inspection and other methods, it can be fully and accurately proved whether the E320E computer board works normally in the DPF engine, thereby ensuring the efficient and stable operation of the excavator and meeting the needs of actual engineering operations.

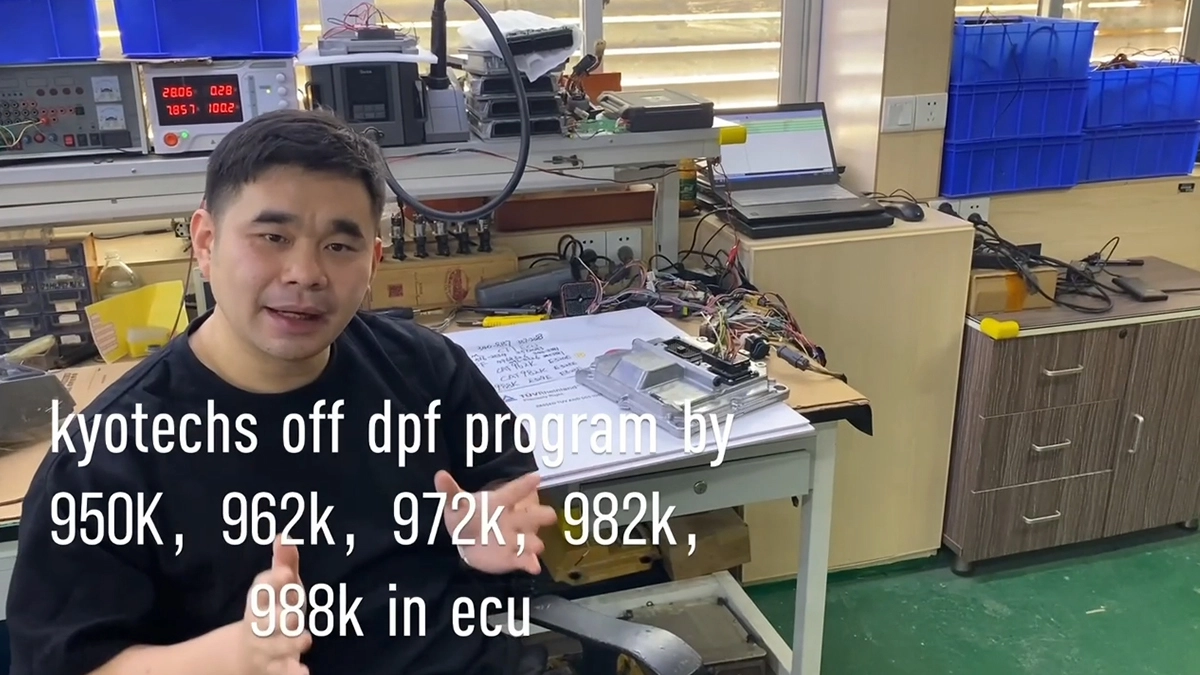

How to turn off the DPF program in the ECU?

How to delete the DPF program from the controller?

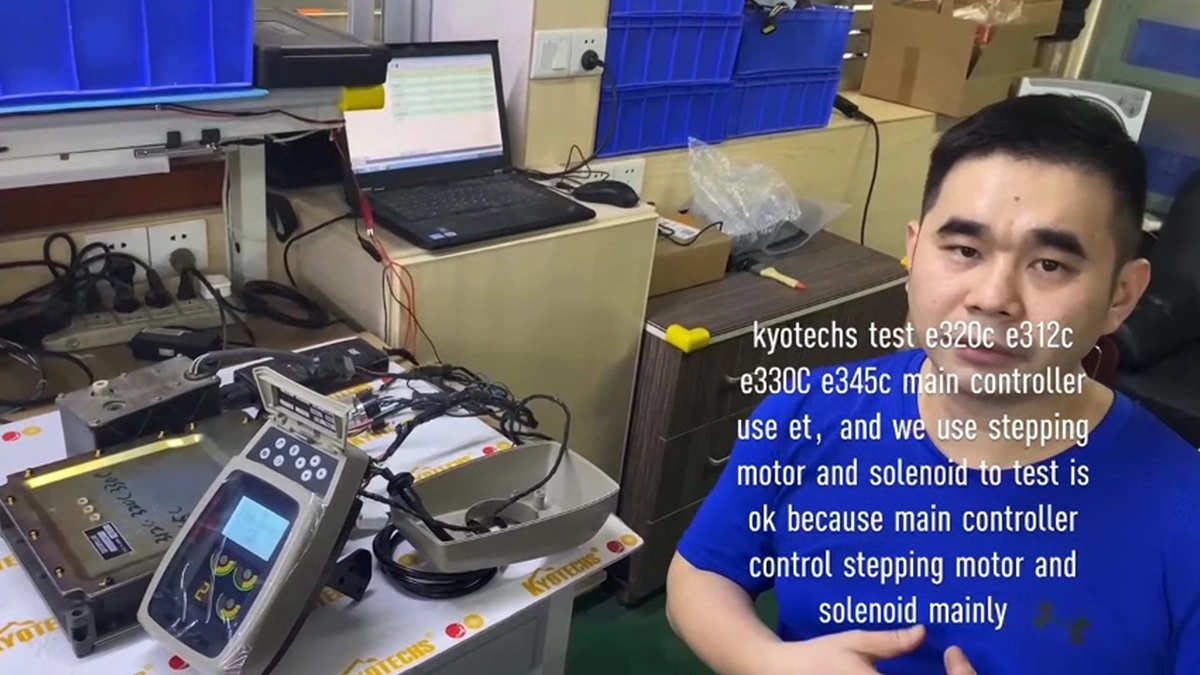

Can the main controller ET be tested with stepper motors and solenoid valves?

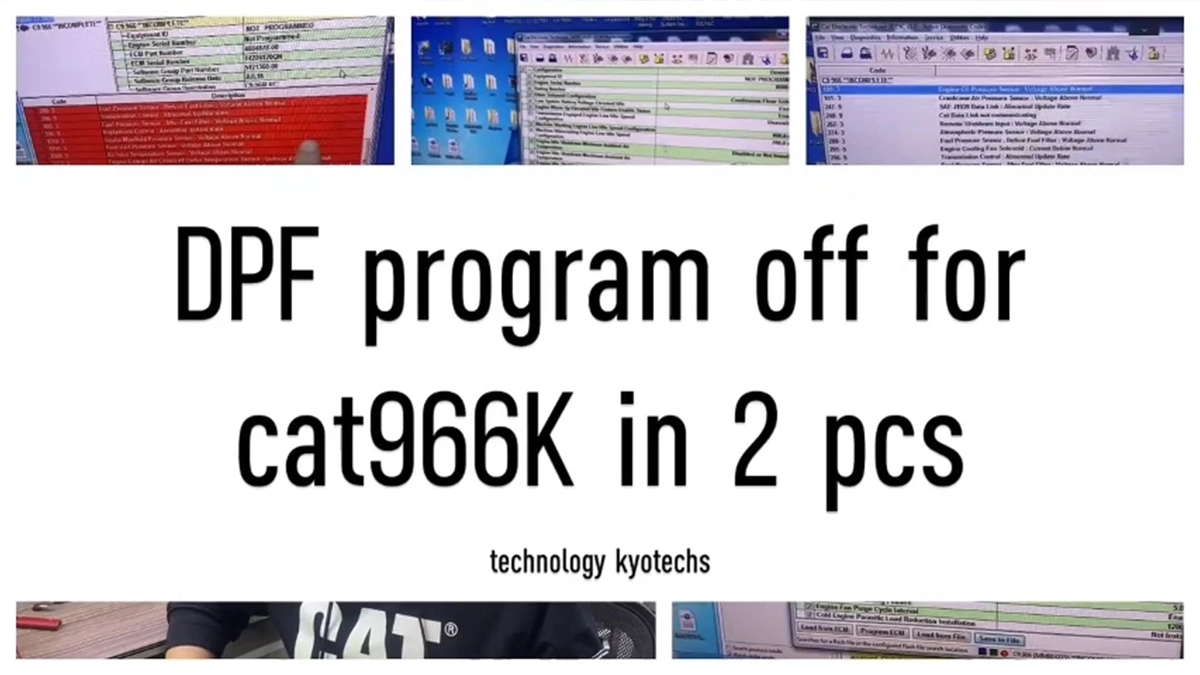

How to check if DPF program is turned off?

How to write program to E320D in ECM?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs