How to diagnose whether the hydraulic pump solenoid valve is normal?

Learn how to diagnose if your hydraulic pump solenoid valve is normal with Kyotechs' expert video guide. This step-by-step tutorial covers essential troubleshooting tips for optimal performance. Watch now for reliable maintenance advice.

The hydraulic pump solenoid valve is a critical component in an excavator's hydraulic system, responsible for controlling the flow and pressure of hydraulic fluid. A malfunctioning solenoid valve can lead to poor performance, increased fuel consumption, and even costly breakdowns.

What preparations are needed?

Before starting any diagnostic procedures on your excavator's hydraulic pump solenoid valve, proper preparation is essential to ensure safety and accuracy:

1.Gather necessary tools

You'll need a multimeter for electrical testing, a pressure gauge set compatible with your excavator's hydraulic system, basic hand tools, and a flashlight.

2.Visual inspection tools

Prepare cleaning supplies for any visible components that may need inspection, and have a container ready to catch any hydraulic fluid that might leak during testing.

3.Safety equipment

Wear appropriate personal protective equipment, including safety glasses, gloves, and steel-toed boots.

What problems might arise during solenoid valve testing?

During solenoid valve testing, several issues may present themselves or interfere with accurate diagnosis:

1.Intermittent failures

The solenoid may work sporadically, making diagnosis challenging. This often indicates a loose connection, worn contacts, or a solenoid approaching failure.

2.Pressure fluctuations

Fluctuating pressure readings could indicate a sticking valve spool, contaminated fluid, or a partially clogged orifice.

3.Electrical interference

Other electrical components on the excavator may cause interference, leading to incorrect multimeter readings. Disconnecting non-essential components during testing can help.

4.Hydraulic system issues masking solenoid problems

Leaks elsewhere in the system, pump wear, or other component failures can produce symptoms similar to solenoid valve issues.

5.Incorrect test procedures

Using improper testing techniques or misinterpreting readings can lead to false conclusions. Always follow the manufacturer's recommended procedures.

6.Environmental factors

Dust, moisture, and temperature extremes can affect both testing equipment and solenoid performance during diagnosis.

How should I perform routine maintenance?

Regular maintenance can prevent many solenoid valve problems and extend their lifespan:

• Regular fluid checks: Inspect hydraulic fluid levels daily and check for contamination monthly. Change fluid and filters according to the manufacturer's schedule.

• Electrical connection maintenance: Periodically inspect and clean electrical connectors, ensuring they're tight and free from corrosion. Apply dielectric grease to protect connections.

• Visual inspections: Check for leaks around the solenoid valve body and connections. Look for signs of physical damage or excessive heat.

• Cleanliness: Keep the area around the solenoid valve clean to prevent debris from entering the system during maintenance.

• Functional testing: Incorporate solenoid valve testing into your regular maintenance schedule using the instrument methods described above.

• Preventative replacement: Consider replacing solenoid valves at recommended intervals, especially in high-hour machines, to prevent unexpected failures.

Conclusion

Diagnosing an excavator's hydraulic pump solenoid valve requires thorough preparation, appropriate instruments, and a systematic approach. Following the steps outlined, you can accurately determine whether the solenoid valve is functioning properly.

Remember, regular maintenance is key to preventing solenoid valve failure. If you have any questions about any aspect of solenoid valve diagnosis or maintenance, please feel free to contact us.

How to prove that the ECU works properly in the DPF engine?

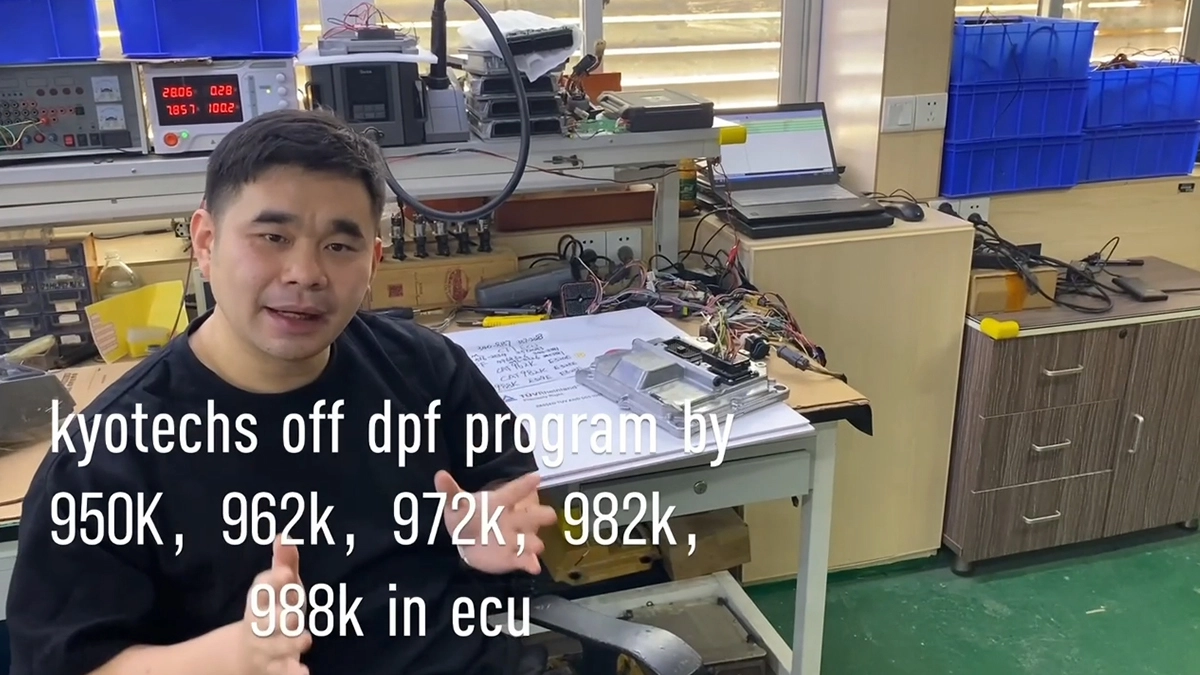

How to turn off the DPF program in the ECU?

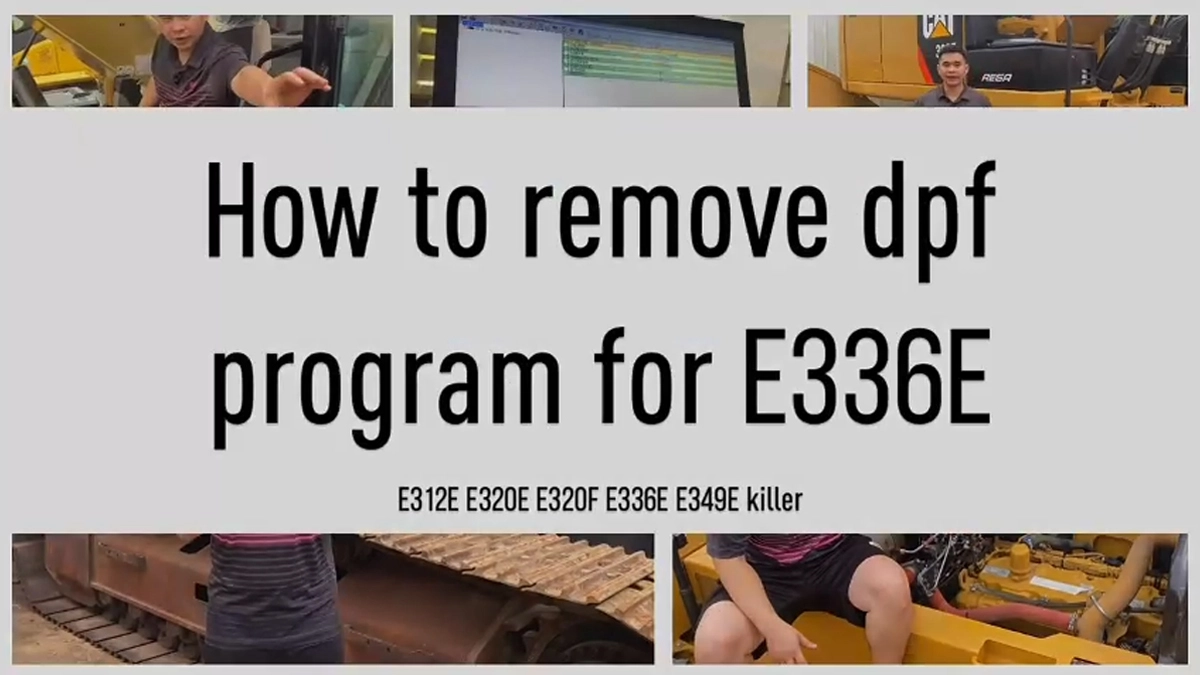

How to delete the DPF program from the controller?

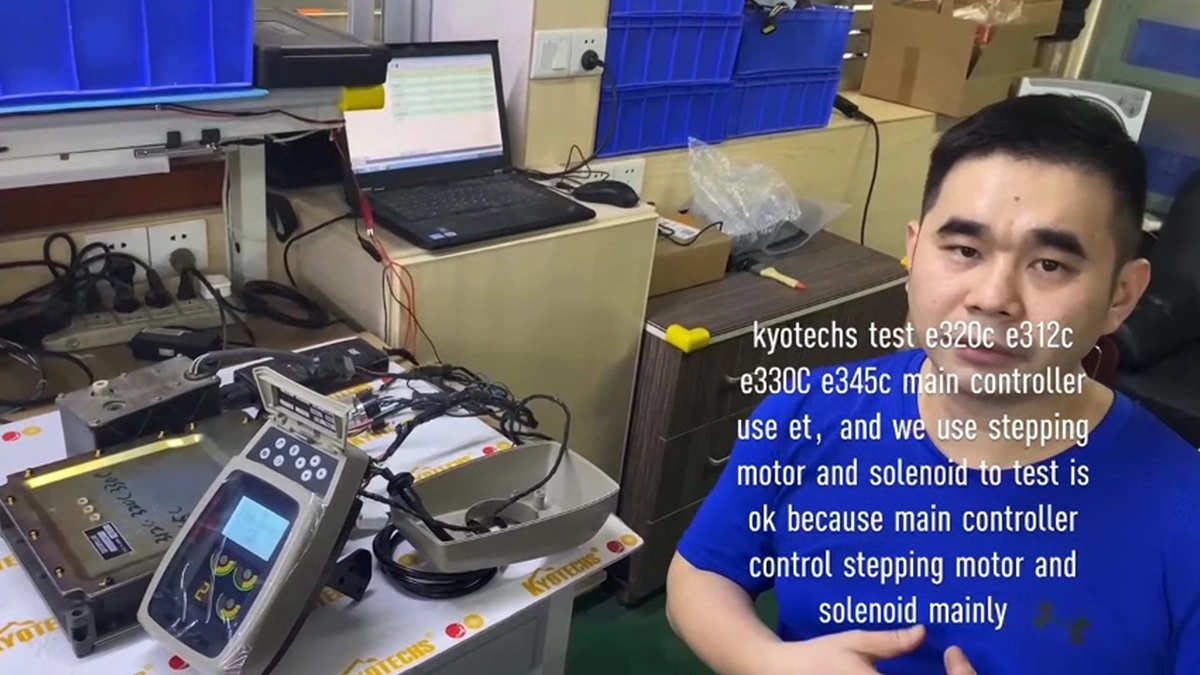

Can the main controller ET be tested with stepper motors and solenoid valves?

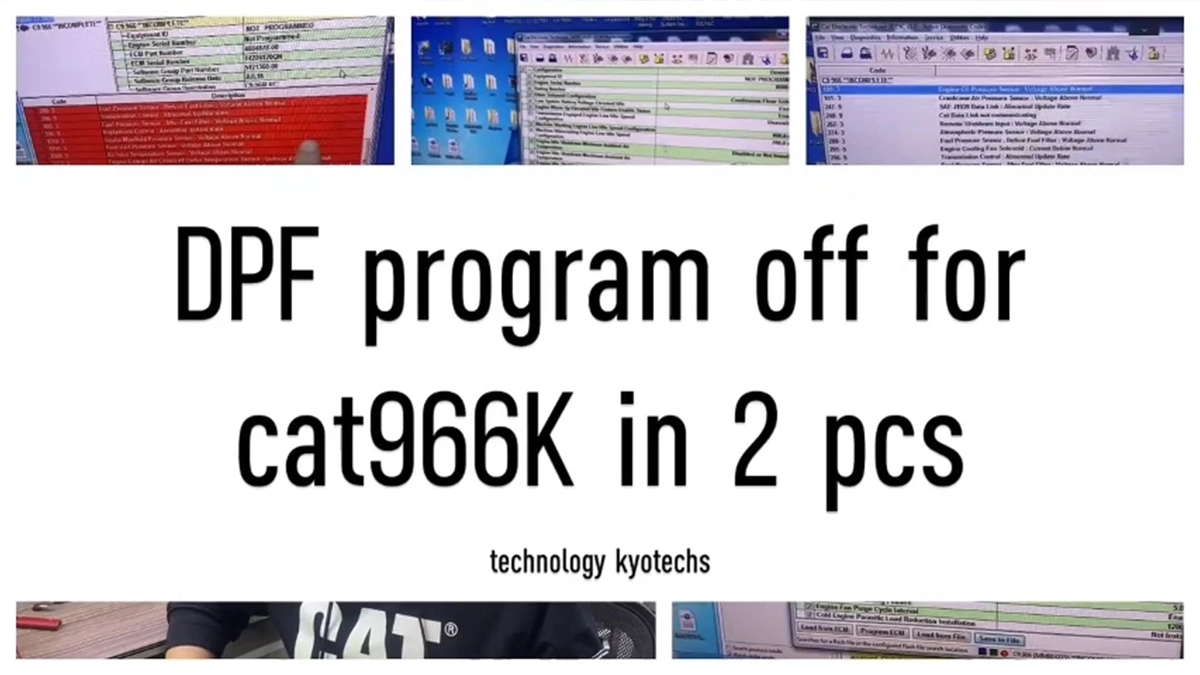

How to check if DPF program is turned off?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs