How to install ECU software for CAT C13 E345C?

Discover how to install ECU software for the CAT C13 E345C with our expert guide from Kyotechs. This video provides step-by-step instructions, ensuring your C13 engine and E345C ECU perform optimally. Enhance your machinery's efficiency and reliability today by following our detailed tutorial. Watch now to seamlessly update your CAT's ECU software.

Let Kyotechs engineer Mark teach you how to do it below

1. Get the right software

Get the latest compatible ECU software version for CAT C13 E345C from Caterpillar official authorized channels. Using unofficial or incompatible software may cause engine failure, performance degradation or even damage to the ECU.

Make sure the software files are stored in a safe and easily accessible location, such as using a USB flash drive formatted in FAT32, because some ECU reading devices may not support other file systems.

2. Check the device status

Check whether the ECU itself has physical damage, such as cracked housing, bent pins or corrosion. If there is damage, repair or replace the ECU first.

Make sure the engine is stopped and the negative battery cable is disconnected to prevent electrical shorts or damage to electronic components during installation.

3. Prepare necessary tools

Prepare special diagnostic tools, such as Caterpillar's Electronic Technician Tool (ET). This tool is a key device for communicating and programming with the ECU. Please ensure that its hardware is intact, the software version is up to date and compatible with the target ECU.

Prepare basic hand tools such as wrenches and screwdrivers for removing and installing parts that may prevent access to the ECU.

Ensure that the power supply is reliable to avoid power outages during installation that may cause program interruptions and ECU damage.

What equipment needs to be connected?

1. Locate the ECU

Consult the CAT C13 E345C engine maintenance manual to understand the specific installation location of the ECU. Usually the ECU is installed in a relatively dry, safe, and easy-to-wire location in the engine compartment.

2. Connect the diagnostic tool

Use a suitable communication cable to connect the diagnostic tool (such as ET) to the diagnostic interface of the ECU. Ensure that the connection is firm to avoid looseness or poor contact that may cause communication interruption.

Connect the diagnostic tool to the computer, turn on the power switch of the diagnostic tool, and start the relevant diagnostic software.

What necessary software should be installed?

1. Establish communication

Select the correct engine model (CAT C13 E345C) and ECU type in the diagnostic software, set up communication according to the software prompts, and establish a communication connection between the diagnostic tool and the ECU.

If communication fails, please check whether the connection cable is normal, whether the diagnostic interface is damaged, and whether the software settings are correct.

2. Back up the original data

Before installing the new ECU software, be sure to use the diagnostic software to back up the existing data in the ECU. This data includes engine operating parameters, fault codes, etc., so that it can be restored to the original state if there is a problem during the installation process.

3. Install new software

Select the "Software Update" or "Programming" function in the diagnostic software, and then specify the new ECU software file stored in the USB flash drive or other storage device.

Follow the software prompts step by step to start the software installation process. During the installation process, the diagnostic software will write the new software code to the memory of the ECU. This process may take several minutes to tens of minutes. Do not interrupt the power supply or perform other operations during this period.

4. Verify the installation results

After the software is installed, the diagnostic software will perform a self-test to check whether the new software is successfully written to the ECU. If the self-test passes, the software installation is successful.

Reconnect the negative battery cable, start the engine, observe the engine running status, and check for abnormal sounds, jitters, fault indicator lights, etc.

If you encounter any problems during this process, please feel free to contact us.

How to prove that the ECU works properly in the DPF engine?

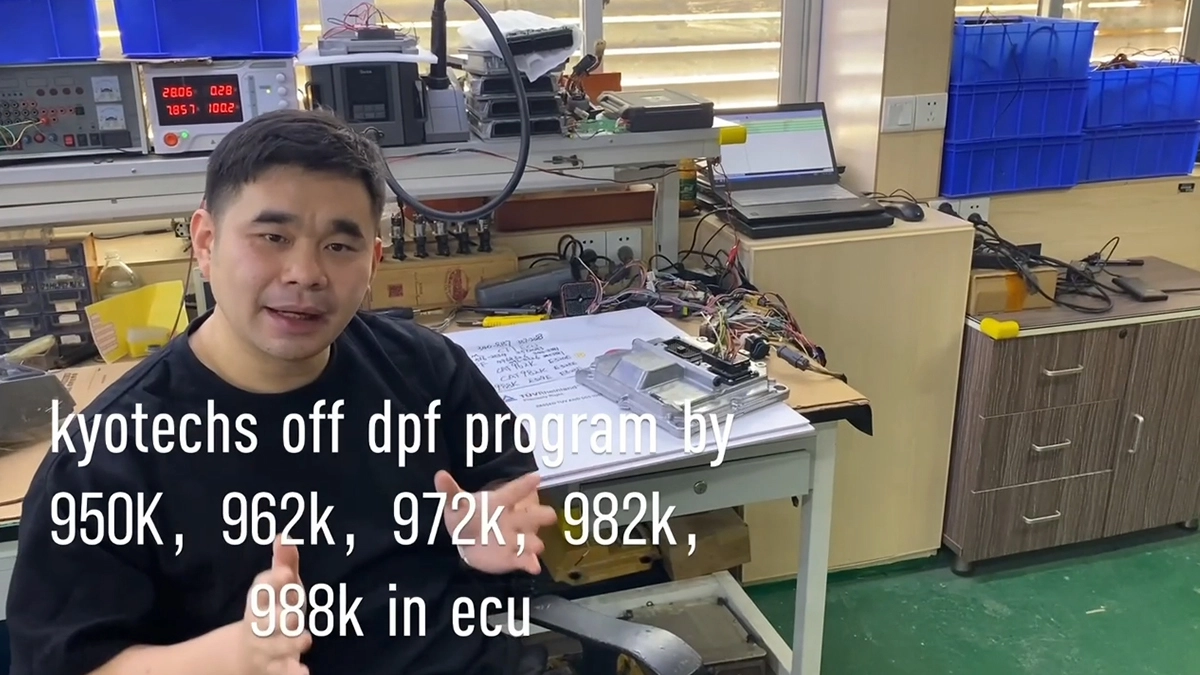

How to turn off the DPF program in the ECU?

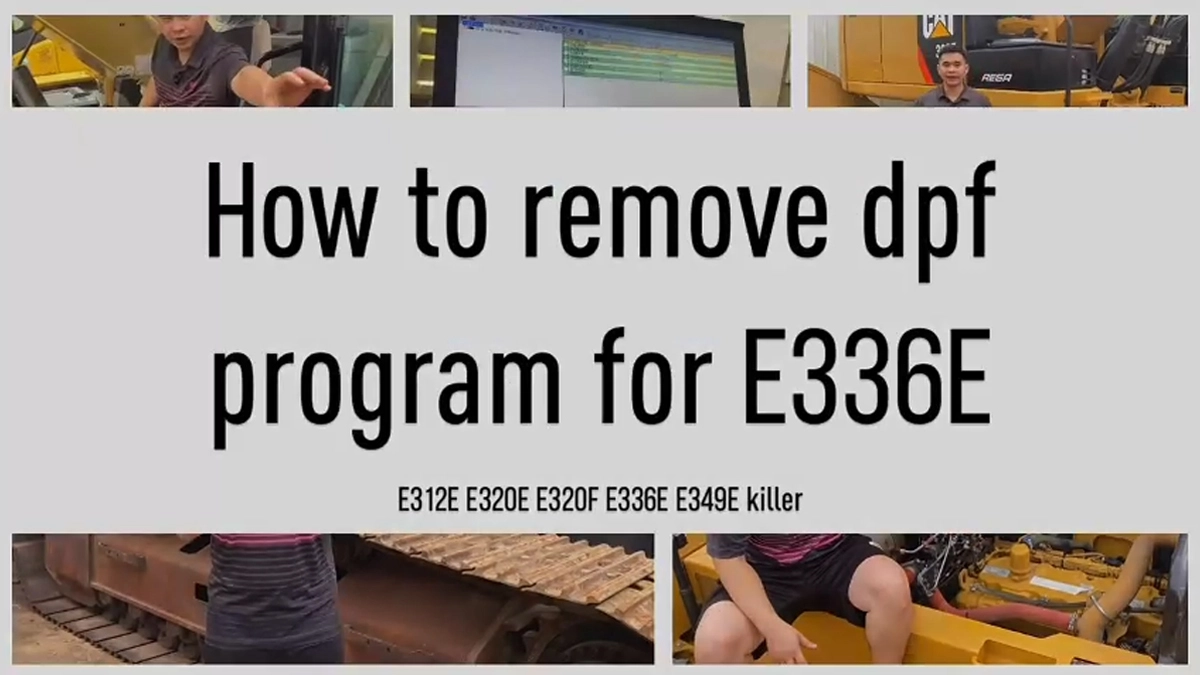

How to delete the DPF program from the controller?

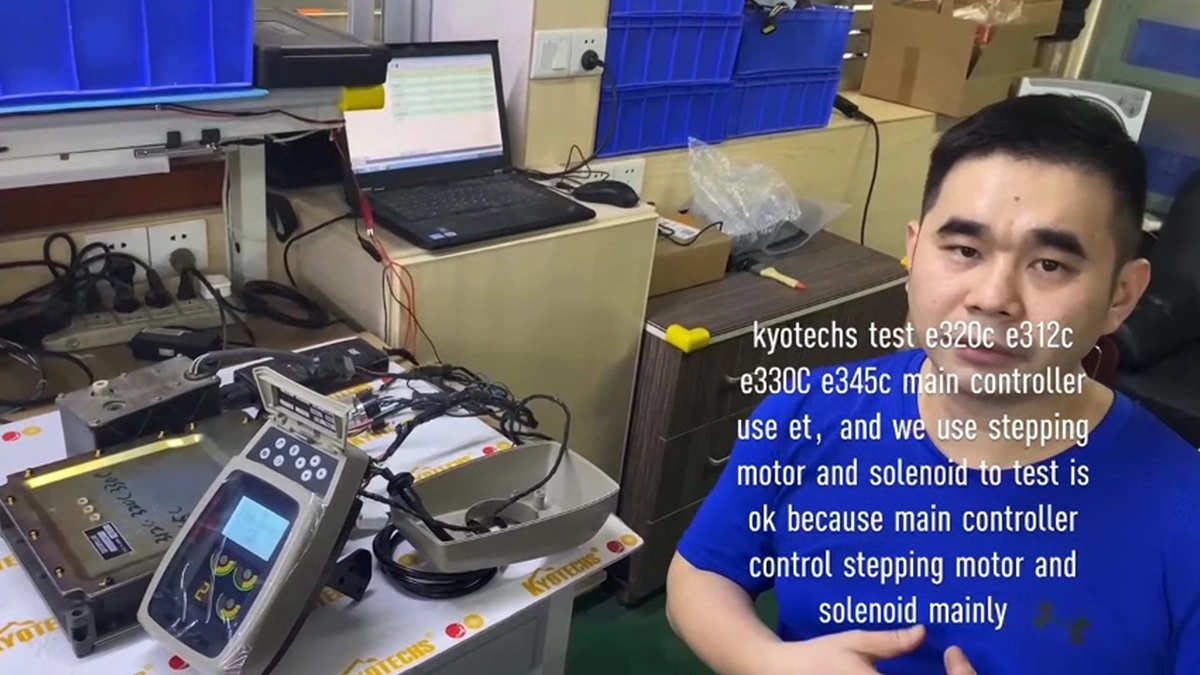

Can the main controller ET be tested with stepper motors and solenoid valves?

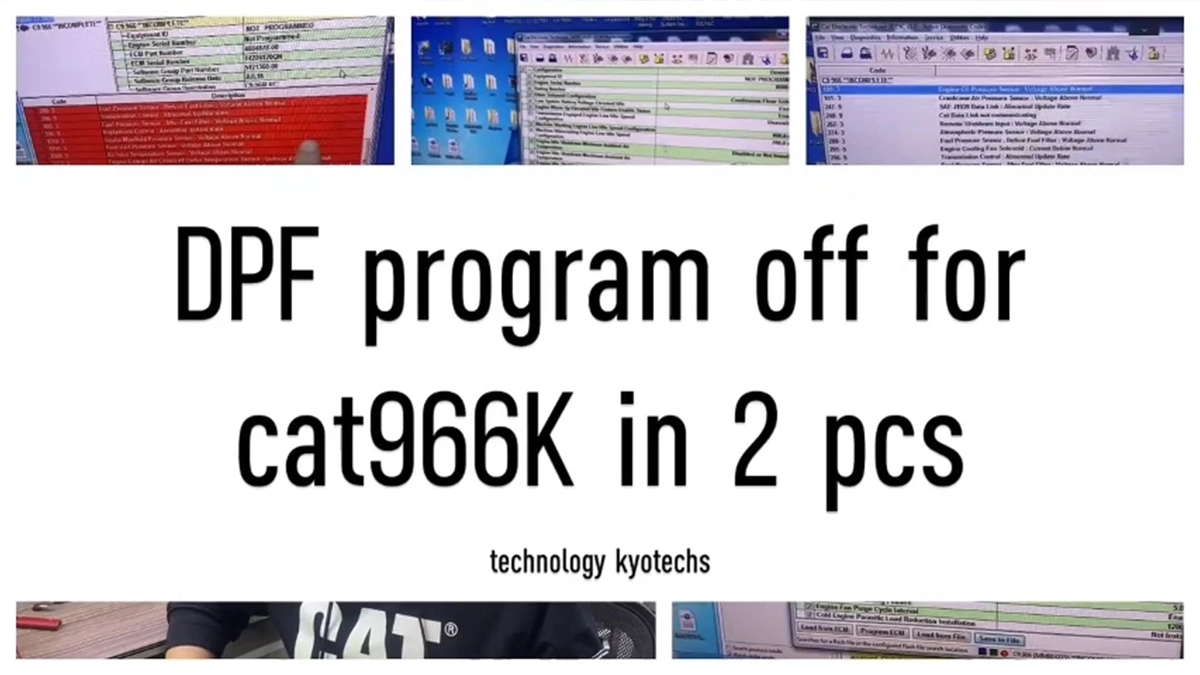

How to check if DPF program is turned off?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs