How to install software into the E324D ECU?

Preparation

Get the right software:

Contact the device manufacturer or its authorized agent to get a software package designed specifically for the E324D ECU. Make sure the software version matches your device model and ECU specifications to avoid problems such as device failure or performance degradation due to software incompatibility. At the same time, be sure to obtain software from official and reliable channels to prevent the use of pirated or unidentified software to avoid security risks and legal risks.

Prepare hardware equipment:

Prepare a computer that meets the software running requirements, ensure that the computer operating system is compatible with the installation software, and have sufficient memory, storage space and processing power. In addition, a dedicated data cable is required to connect the computer to the E324D ECU. Different models of ECU may correspond to data cables with different interfaces, so be sure to ensure that the cable is compatible.

Understand ECU information:

Be familiar with the basic information of the E324D ECU, such as the operating voltage (generally 24V, but allowed to fluctuate within the range of 9 - 32V), connector specifications (for example, 141Pins, specifically a combination of 16 + 36 + 89), etc. This information helps to correctly connect the device during the installation process to avoid damage to the ECU or other devices due to voltage mismatch or incorrect connector connection.

Installation steps

Connect the device:

Turn off the power of E324D excavator and computer, and use the dedicated data cable to connect the computer to the ECU interface of E324D. Make sure the connection is firm to avoid data transmission interruption caused by looseness during installation. After the connection is completed, turn on the computer and wait for the operating system to recognize the newly connected device.

Read the current program version:

Run the diagnostic tool software provided by the manufacturer on the computer. The software can establish a communication connection with the ECU of E324D and read the program version information currently running in ECU. Record this information so that you can compare the version difference before and after installing the new software and confirm whether the installation is successful.

Install the software:

Open the obtained software installation package and follow the prompts of the installation wizard step by step. During the installation process, you may be prompted to select options such as installation path. It is recommended to keep the default settings unless you have special requirements for software installation. During the installation process, the software may automatically perform some system configuration and file copy operations. Please be patient and do not interrupt the installation process.

Write software to ECU:

After installation, run the installed software. In the software interface, find the function option for writing software to ECU, which usually has a clear prompt or button. Click this option and the software will start writing new program data to the E324D ECU. This process may take several minutes. During this period, please ensure that the device connection is stable, the computer and ECU are in normal operation, and do not perform other operations that may interfere with data transmission.

Post-installation check

Verify the software version:

After writing, use the diagnostic tool to read the ECU program version of E324D again to confirm that the software has been successfully installed and the version has been updated to the expected new version. Compare the version information of the new version with that before installation to check whether there are any version inconsistencies or abnormalities.

Function test:

Start the E324D excavator and perform a series of functional tests, including but not limited to engine start, excavation operation, and monitoring of various equipment parameters. Check the operating status of the excavator under the new software, observe whether there are abnormal noises and vibrations, whether various functions respond normally, and whether the equipment performance has been improved. If any abnormalities are found, contact the technician in time for investigation and treatment.

Precautions

Static electricity protection:

During operation, static electricity generated by the human body may cause damage to electronic equipment such as ECU. Therefore, it is recommended that operators wear anti-static wristbands or release their own static electricity by touching grounded metal objects before operation to avoid irreversible damage to the equipment caused by static electricity.

Installation environment:

Select a clean, dry environment without strong electromagnetic interference for software installation. Strong electromagnetic interference may affect the stability of data transmission, resulting in installation failure or software writing errors. At the same time, avoid operating in high temperature, humid or dusty environments to avoid adverse effects on the equipment and installation process.

If you have any questions during this process, you can come to Kyotechs for consultation and we will answer all your questions

How to prove that the ECU works properly in the DPF engine?

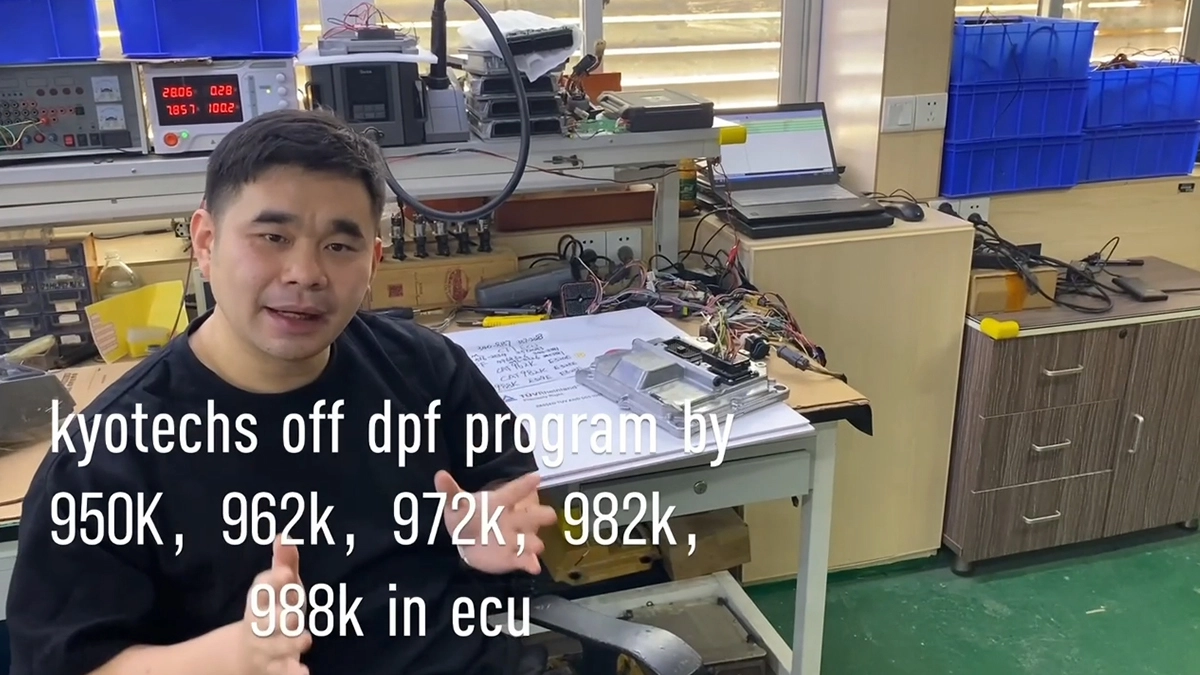

How to turn off the DPF program in the ECU?

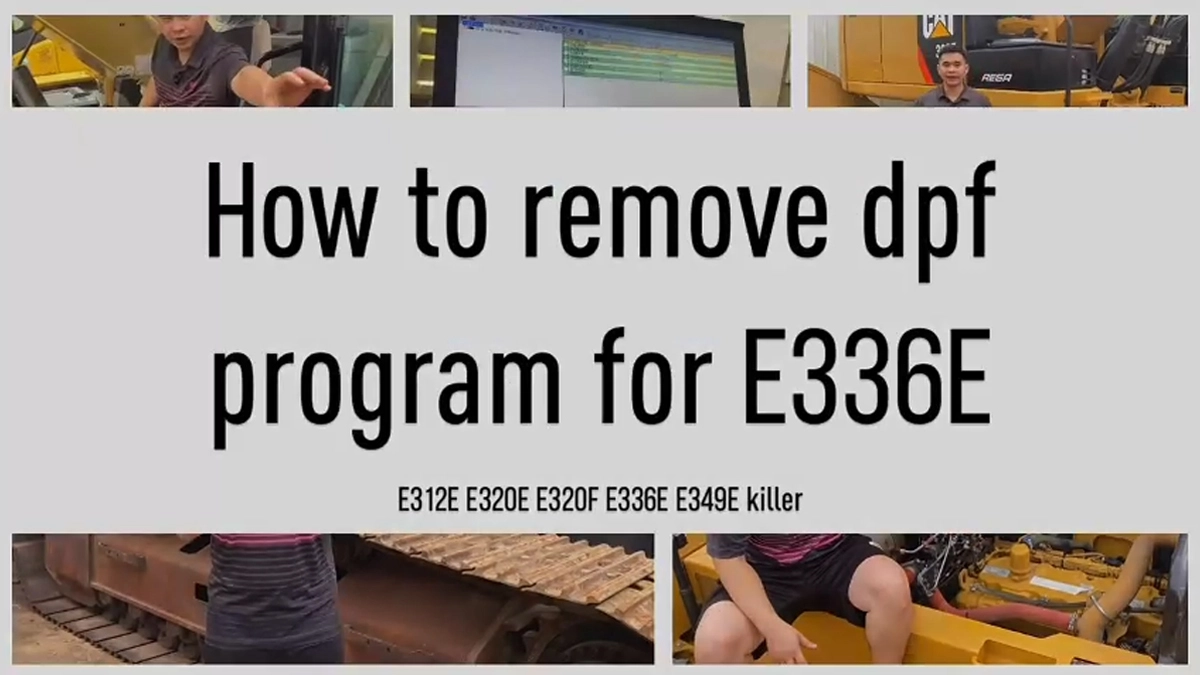

How to delete the DPF program from the controller?

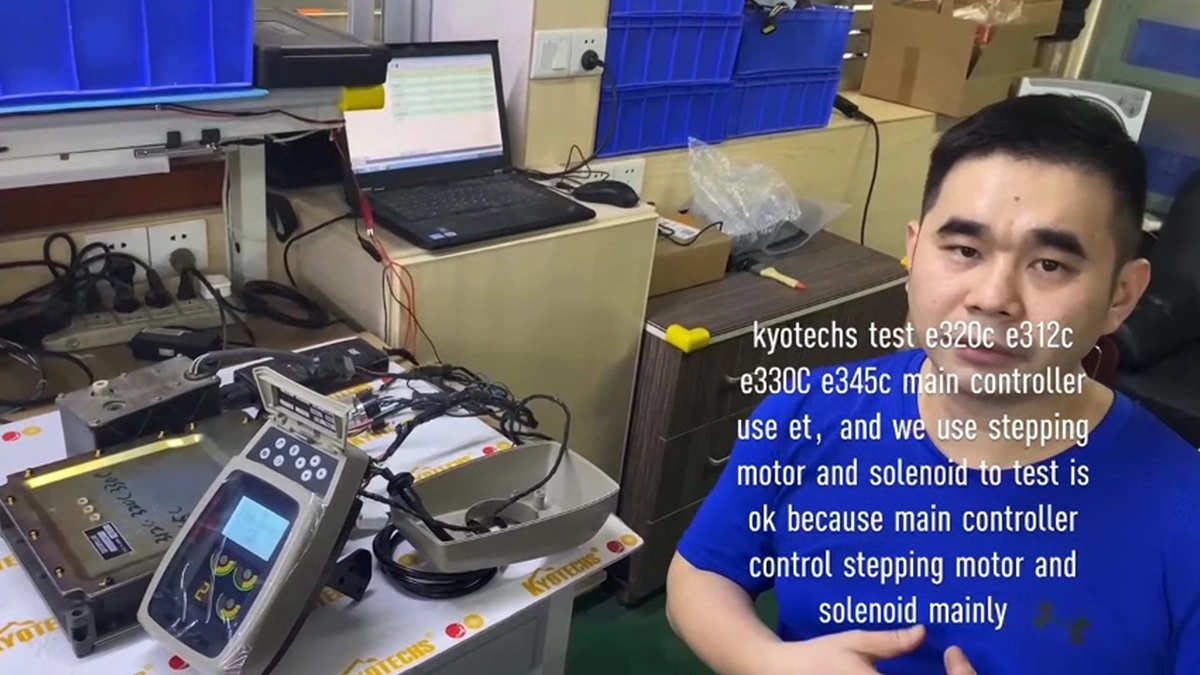

Can the main controller ET be tested with stepper motors and solenoid valves?

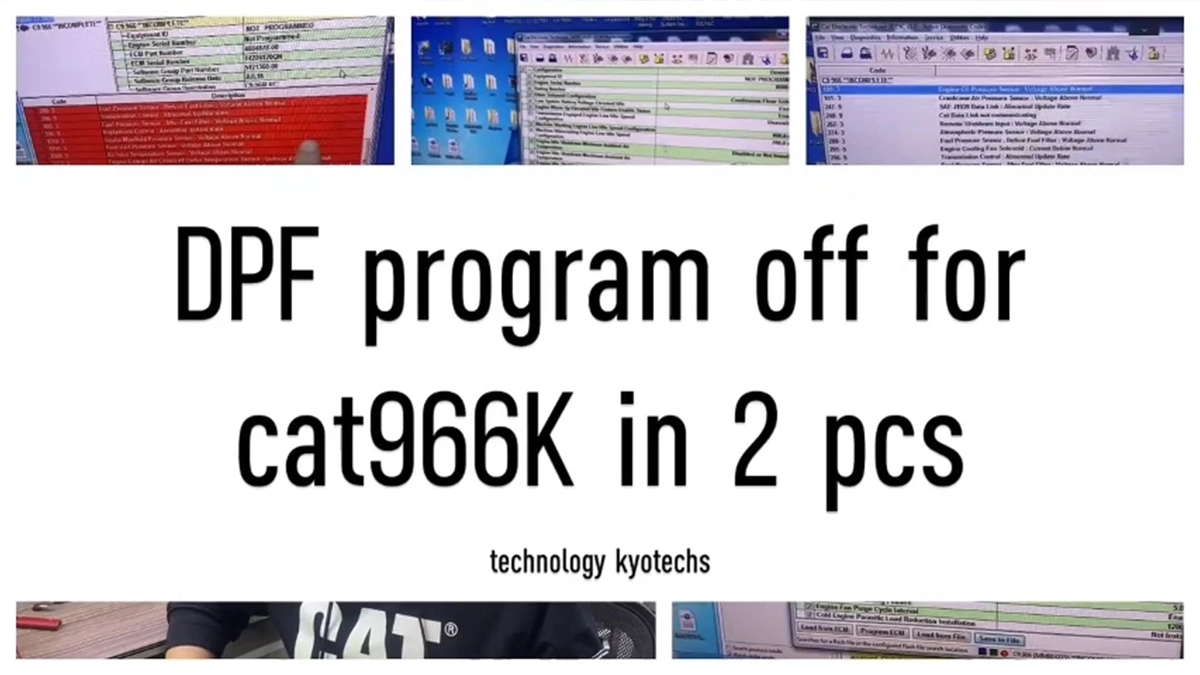

How to check if DPF program is turned off?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs