How to put software into E320D ECM with part numbers 2218874 3668821?

Discover how to upload software to the E320D ECM using Kyotechs part numbers 2218874 and 3668821 in this instructional video. Learn step-by-step procedures to ensure optimal performance and reliability. Ideal for technicians seeking precise solutions. Watch now to enhance your understanding and skills with our comprehensive guide.

Kyotechs teaches you how to put programs into the empty ECM of E320D E323D E325D E329D E336D E345D E374D E390D

In the maintenance and upgrade of excavators, correctly writing programs for the electronic control module (ECM) is a key link to ensure its normal operation and optimal performance. For Caterpillar's E320D, E323D, E325D, E329D, E336D, E345D, E374D, E390D and other models of excavators, Kyotechs provides you with detailed guidance on writing empty ECM programs with professional technology and rich experience.

What do you need to prepare in advance?

Hardware preparation

1. Programming equipment:

Kyotechs recommends using a professional programmer that matches these excavator models, such as [Specific Model Programmer]. This programmer has high-speed and stable data transmission capabilities, and can accurately write programs to the ECM while ensuring the safety and integrity of the writing process.

2. Connection cable:

Prepare an appropriate connection cable to ensure that the programmer and the excavator's ECM can be reliably connected. The quality of the cable is crucial. Poor-quality cables may cause data transmission interruptions or errors, affecting the program writing effect. Before use, carefully check whether the cable is damaged or short-circuited.

3. Power supply guarantee:

To ensure stable power supply throughout the entire writing process, it is necessary to ensure that the excavator's battery is fully charged, or use a reliable external regulated power supply to power the excavator. Unstable power supply may cause program loss or damage during the writing process, or even damage the ECM.

4. Anti-static equipment:

Since ECM is a precision electronic component, it is sensitive to static electricity. During operation, be sure to wear an anti-static wristband and use an anti-static workbench mat to prevent static electricity from causing irreversible damage to the ECM.

Software preparation

1. Program file:

Get the latest program file of the ECM of the corresponding excavator model from the official channel of Kyotechs. Ensure the integrity and correctness of the program file to avoid writing failure or abnormal operation of the excavator due to program file errors. Different models of excavators have different ECM programs, so be sure to download the correct program file.

2. Programming software:

Install the programming software that comes with the programmer, which is responsible for controlling the data interaction between the programmer and the ECM. Before installing the programming software, check whether the computer system meets the software's operating requirements, such as the operating system version, memory size, etc. After the installation is complete, initialize the software to ensure that it can recognize the programmer normally.

What are the steps?

1.Connect the device

Connect the programmer to the ECM interface of the excavator through the adapter cable. During the connection process, make sure that the interface is correctly and firmly connected to avoid poor data transmission due to loose connection. After the interface is connected, check the indicator light status of the programmer to confirm whether the connection is normal.

Connect the programmer to the computer through USB or other data transmission interface. Make sure that the computer can correctly identify the programmer, such as you can see in the device manager that the relevant driver of the programmer has been correctly installed.

2.Start the programming software

Open the programming software installed on the computer. After the software is started, select the corresponding excavator model and the ECM program file to be written in the software interface. Carefully check whether the selected model and program file are correct. If the wrong selection is made, it may cause program writing errors and affect the normal use of the excavator.

Set the programming parameters, such as programming speed, verification method, etc., according to the prompts of the programming software. In general, it is recommended to use the default settings to ensure the stability and reliability of the programming process. However, in some special cases, such as for a specific ECM version or when encountering compatibility issues, it may be necessary to adjust the parameters appropriately according to the guidance of the technical documentation.

3.Start writing the program

Click the "Start Programming" button in the programming software interface, and the programming software will start writing the program to the ECM. During the writing process, be sure to keep the device stable to avoid being affected by vibration, electromagnetic interference and other factors. At the same time, pay close attention to the progress bar and status prompts on the programming software interface to understand the real-time progress of the program writing.

The writing process may take a certain amount of time, depending on the size of the program file and the performance of the programmer. During this period, do not close the programming software, disconnect the device, or perform other operations on the excavator. If an error message appears during the writing process, such as "Data Verification Failed" or "Connection Interrupted", the writing operation should be stopped immediately and the error message should be checked and resolved. Common problems may include loose connection cables, damaged program files, ECM hardware failures, etc.

4.Verification and confirmation

After the program is written, the programming software will automatically verify the written program to ensure the accuracy and completeness of the program. The verification process also requires patience. After the verification is passed, the software interface will display the prompt message "Programming Successful".

To further confirm that the program has been written correctly and the ECM can work properly, the program information in the ECM can be read through the programming software and compared with the original program file. At the same time, perform a simple functional test on the excavator, such as starting the engine, operating the working device, etc., to observe whether the operating status of the excavator is normal. If any abnormality is found, the program writing process should be rechecked in time or other possible problems should be checked.

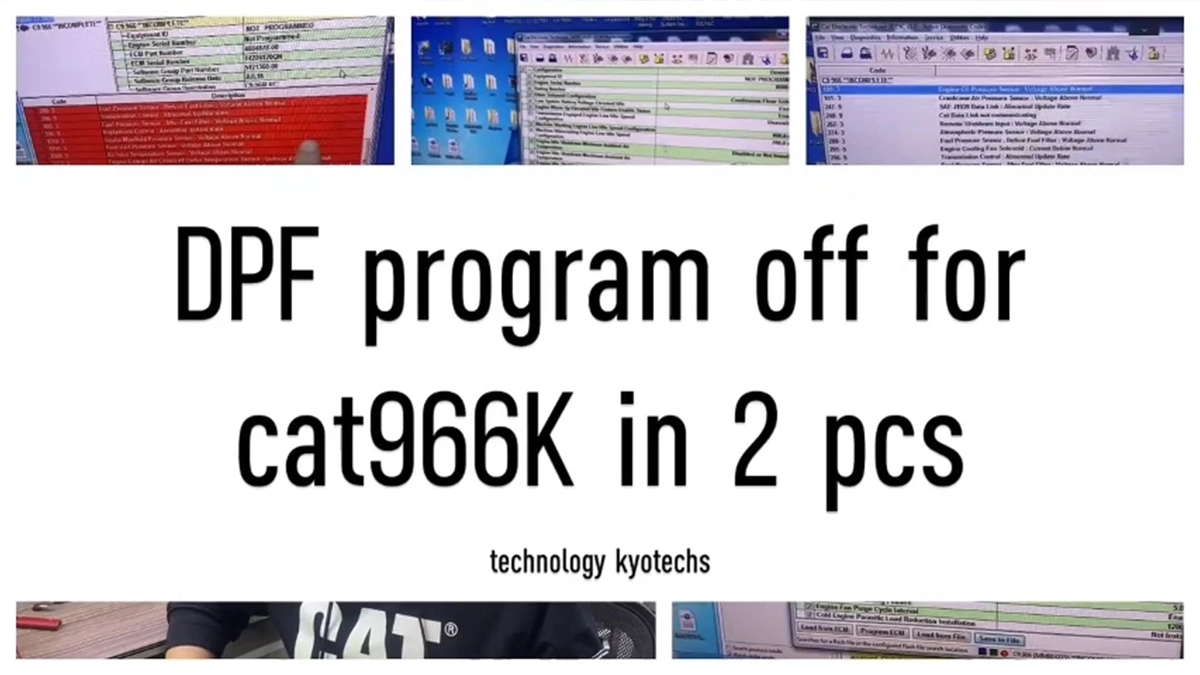

How to prove that the ECU works properly in the DPF engine?

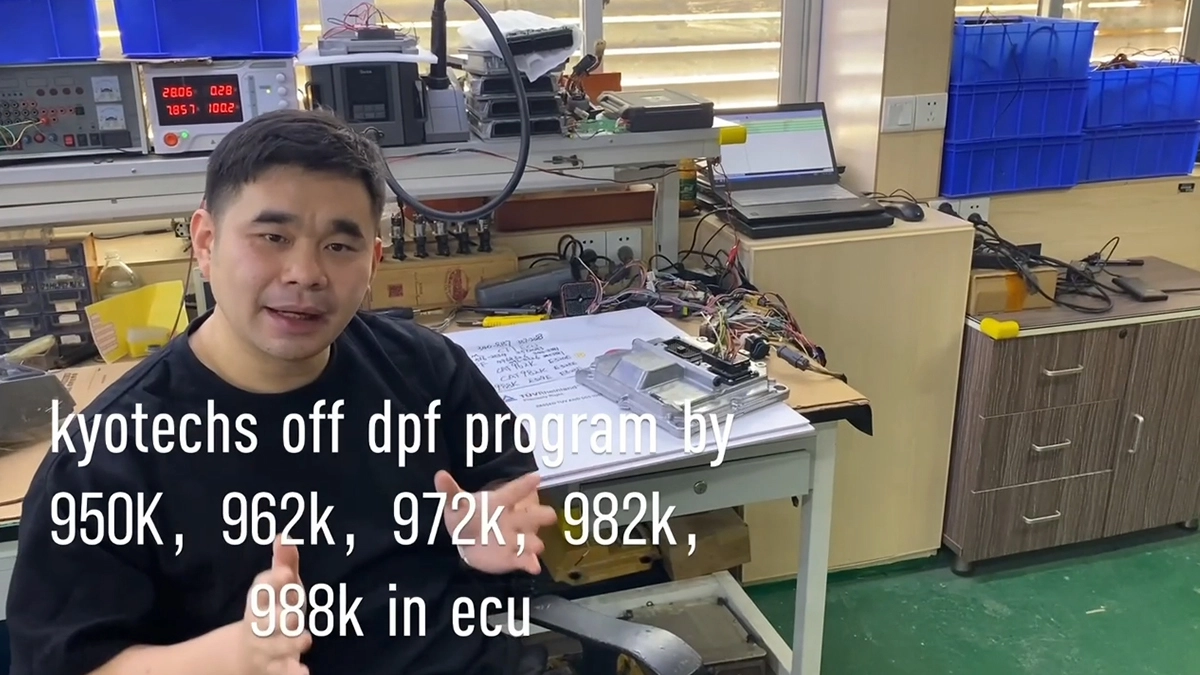

How to turn off the DPF program in the ECU?

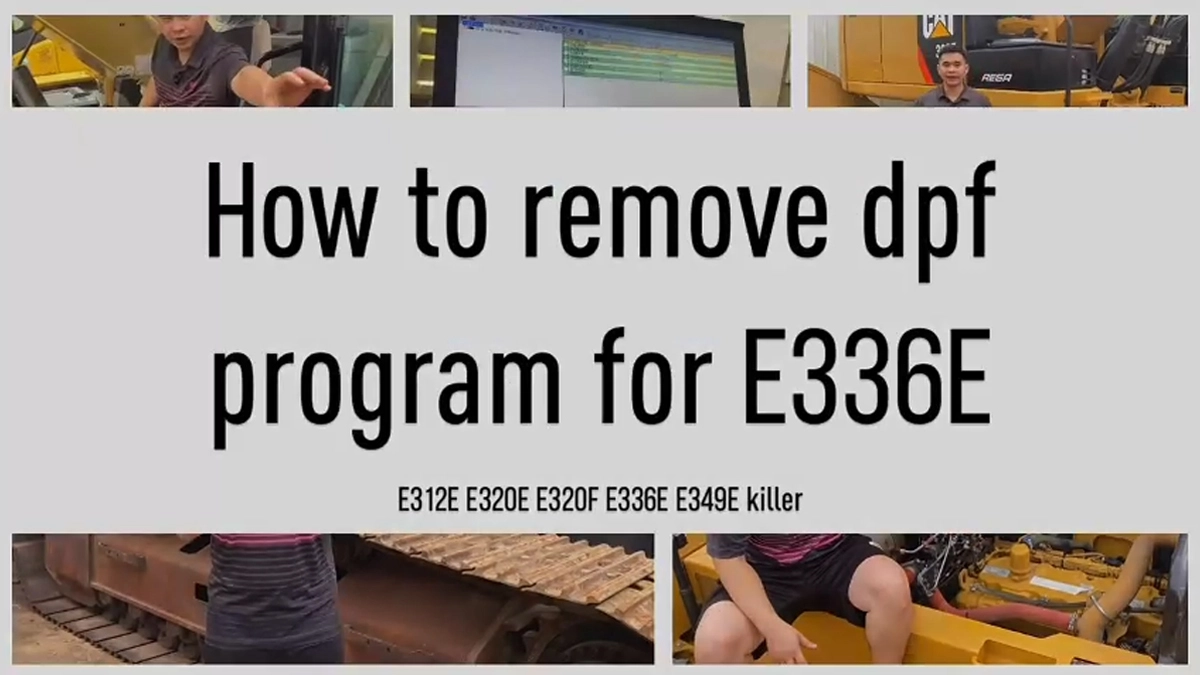

How to delete the DPF program from the controller?

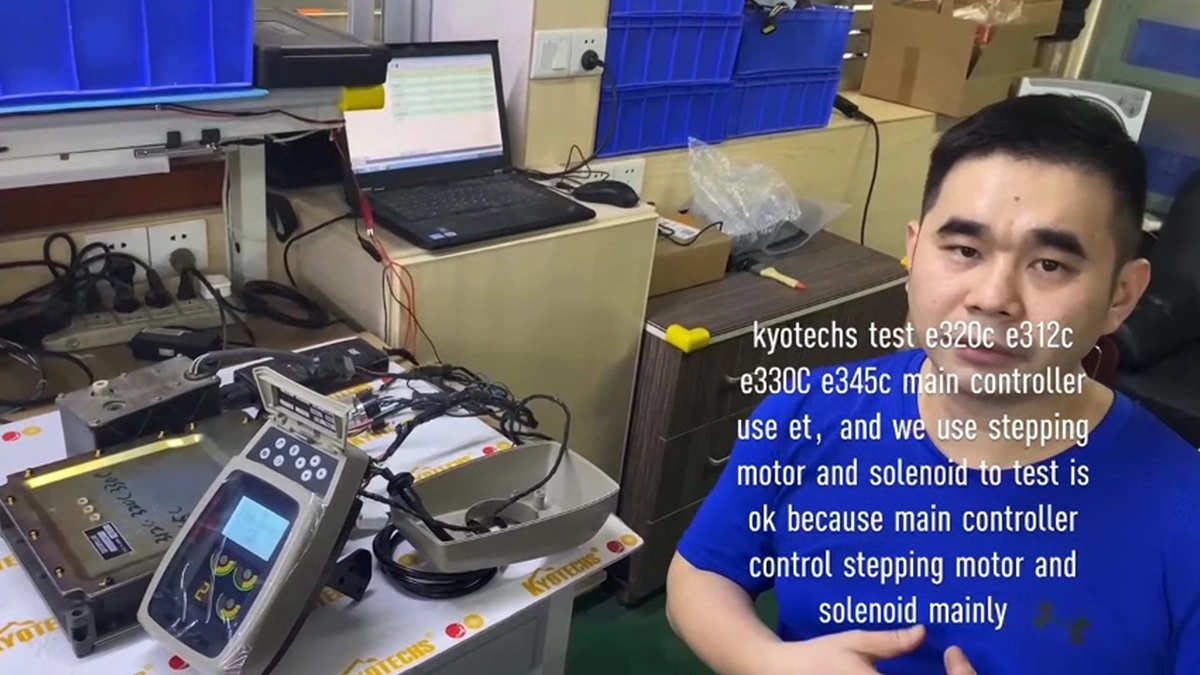

Can the main controller ET be tested with stepper motors and solenoid valves?

How to check if DPF program is turned off?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs