Why did the engine speed increase after replacing the main controller and display?

Discover why the engine speed increased after replacing the main controller and display in our latest Kyotechs video. Explore insights on the 2218874 controller and learn how the change affects overall system performance. Get in-depth explanations and technical expertise to enhance your understanding. Watch now to ensure your equipment operates smoothly and efficiently with Kyotechs solutions.

In the complex system of the excavator, the main controller is like the "brain" of the device, and the display is an important window for human-computer interaction. When these two key components are replaced, the engine speed increases, which contains many factors.

First, there is a close control logic connection between the main controller and the engine. The main controller of the excavator is responsible for receiving signals from various sensors, including engine speed sensors, hydraulic system pressure sensors, etc., and accurately controls the operating status of the engine according to preset programs and algorithms. There are differences in the control strategies and parameter settings of the main controllers of excavators of different brands and models. When the newly replaced main controller is not accurately matched with the original equipment, it may cause abnormal engine speed. For example, the default speed control parameters of the new main controller may not match the optimal operating speed of the original equipment engine, causing the controller to send an incorrect speed command to the engine, thereby increasing the engine speed.

Second, the data communication between the main controller and the display may also affect the engine speed. The display is not only used to show the operator the various operating parameters of the equipment, such as engine speed, hydraulic oil temperature, etc., but also participates in the feedback process of some control instructions. After replacing the display, if there is a compatibility problem with the communication protocol between it and the main controller, data transmission may be incorrect or incomplete. After receiving the wrong feedback information, the main controller will mistakenly think that the engine is in an abnormal condition, and then adjust the speed to maintain the normal operation of the equipment. For example, if the display incorrectly feedbacks to the main controller that the engine load is too low, the main controller may increase the engine speed to increase the output power to meet possible work requirements.

Furthermore, the newly replaced main controller and display may change the operation mode recognition mechanism of the excavator. Modern excavators usually have multiple operation modes, such as economic mode, standard mode and strong mode, and the engine speed settings are different in different modes. The main controller switches the operation mode by identifying the operator's operating habits and the working status of the equipment. The new main controller and display may adjust the recognition algorithm of the operation mode, resulting in the equipment being misjudged as entering the operation mode with high speed requirements under the same operating conditions, thereby increasing the engine speed accordingly.

In addition, the calibration of the sensor cannot be ignored. The various sensors of the excavator play a key monitoring role in the operation of the equipment. They transmit the collected real-time data to the main controller. After replacing the main controller and display, if the relevant sensors are not recalibrated, the signals output by the sensors may deviate from the actual working conditions. For example, if the engine speed sensor is not calibrated accurately, it may transmit a signal higher than the actual speed to the main controller. In order to achieve the set speed target, the main controller will further increase the engine speed, thus forming a vicious circle.

In summary, the increase in engine speed after the excavator replaces the main controller and display is the result of the combined effect of multiple factors. During equipment maintenance and component replacement, maintenance personnel must fully consider these potential factors, ensure the compatibility of the newly replaced components with the original equipment, and accurately debug and calibrate the relevant parameters and sensors to ensure the stable operation and efficient work of the excavator.

If you want to know more, come in and consult us!

How to prove that the ECU works properly in the DPF engine?

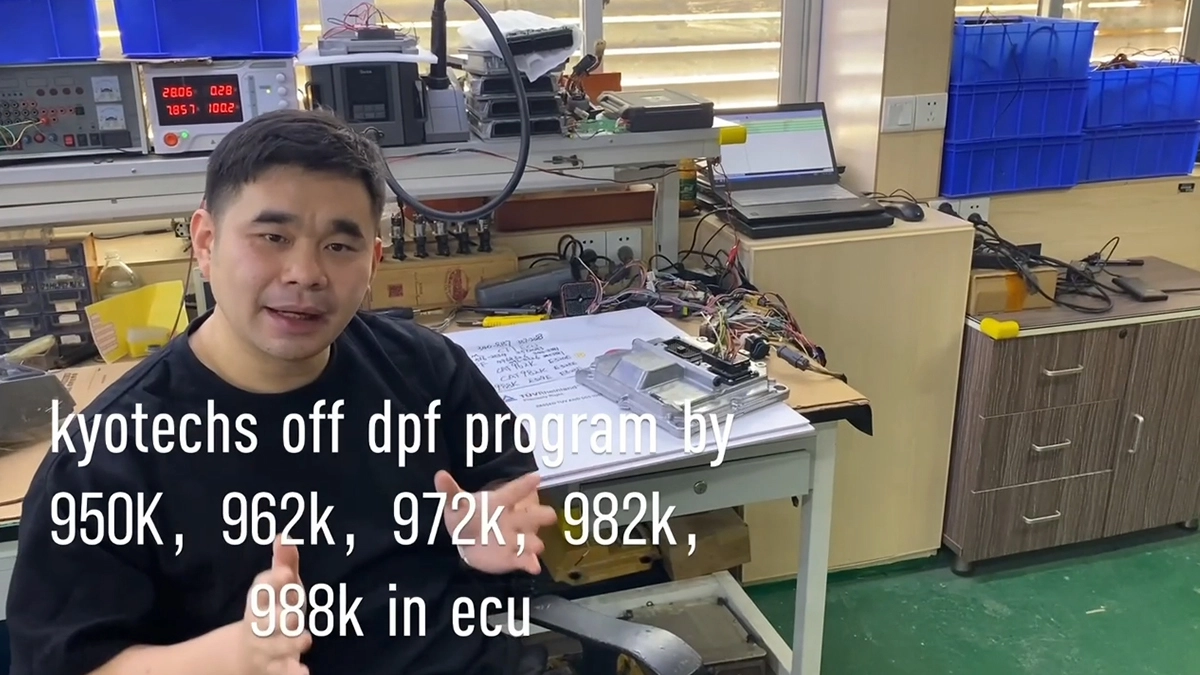

How to turn off the DPF program in the ECU?

How to delete the DPF program from the controller?

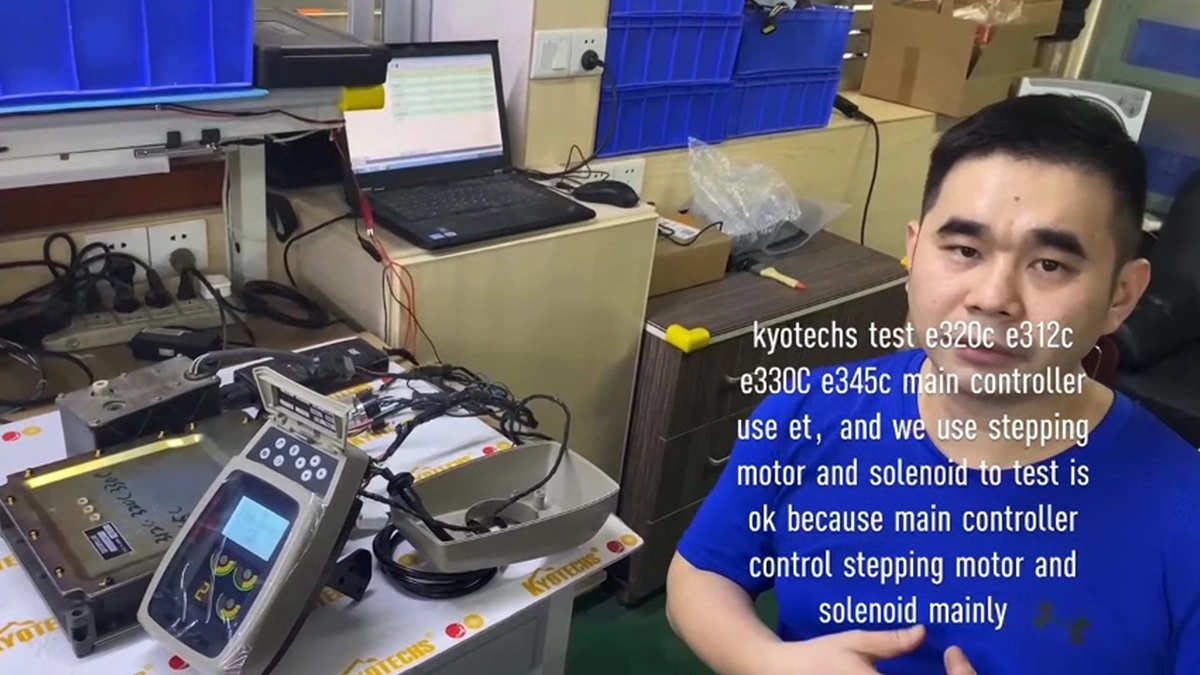

Can the main controller ET be tested with stepper motors and solenoid valves?

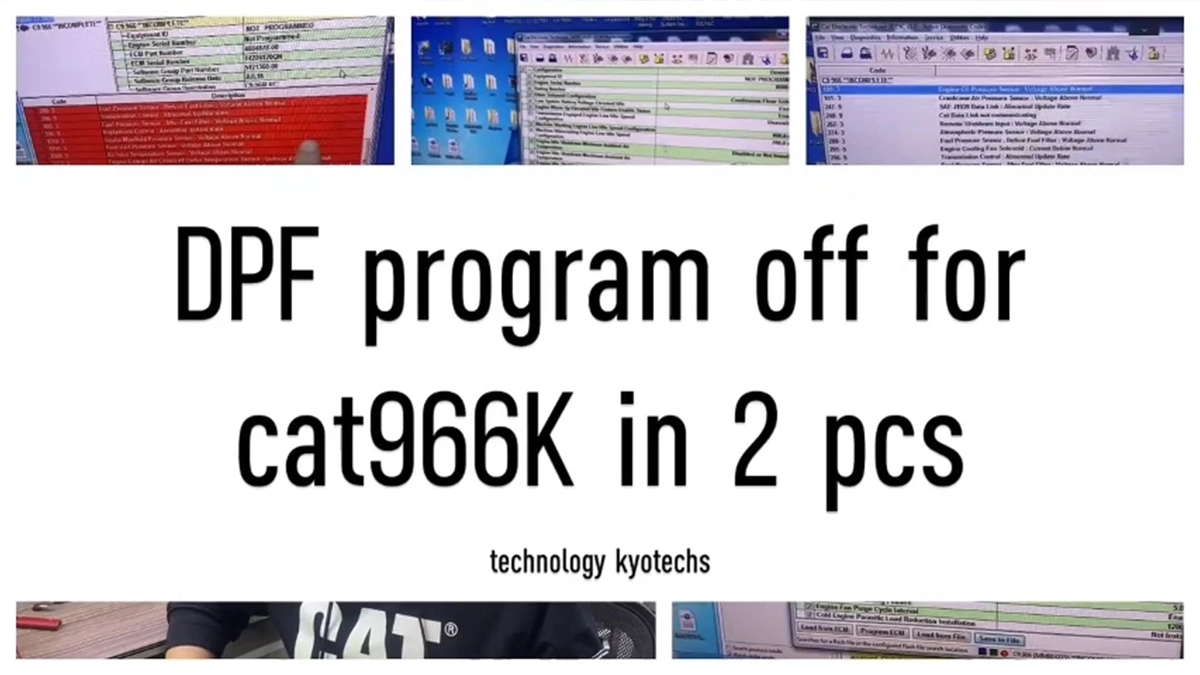

How to check if DPF program is turned off?

Excavator Spare Parts 515-0070 Travel Gearbox For Caterpillar E330D2

Excavator Spare Parts 480-6768 Travel Gearbox For Caterpillar E320D2

Excavator Spare Parts 353-0562 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 333-2907 Travel Gearbox For Caterpillar E324D

Excavator Spare Parts 296-6218 Travel Gearbox For Caterpillar E336D

Excavator Spare Parts 227-6949 Travel Gearbox For Caterpillar E318C E319C E320D

Excavator Parts 14724048 14744890 Swing Motor For Volvo EC350D

Excavator Spare Parts 259-7632 Control Valve For Caterpillar E320D E323D

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2025 KYOTECHS. All Rights Reserved.

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs